Method for detecting non-carbon carbon paper CB surface and CF surface colour development by reference paper

A carbonless copy paper, paper detection technology, applied in the use of pressure replication, measuring devices, instruments, etc., can solve problems such as the inability to determine the quality of the CB surface or the CF surface, and the inability to guide production. Instability factors, the effect of eliminating influencing factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

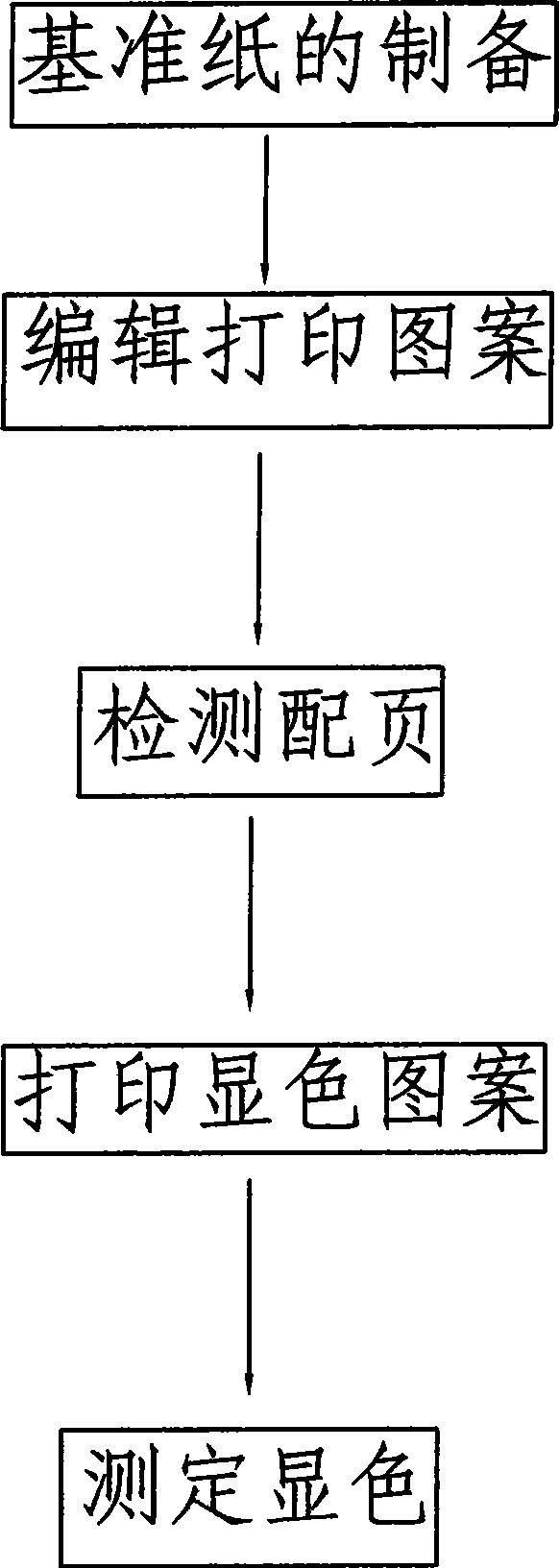

Image

Examples

Embodiment 1

[0037] The six-part carbonless copy paper used as a bill, the method for detecting the qualification of the CB side and the CF side of the carbonless copy paper in production, and using the reference paper to detect the color development of the CB side and the CF side of the carbonless copy paper, comprises the following steps:

[0038] The first step: the preparation of reference paper,

[0039] A, preparation benchmark CB paper: with 400 parts of water, 40 parts of wheat starch spacers, 5 parts of tapioca adhesives, 120 parts of pressure-sensitive melamine formaldehyde resin microcapsules with a solid content of 40%, fatty alcohol polyether defoamer 1 Parts are mixed evenly to make CB paint, and the CB paint is coated at 40g / m 2 On the front side of base paper, the coating weight is 5g / m 2 , cut the coated CB paper into A4 size to make benchmark CB paper;

[0040] B. Preparation of benchmark CF paper: 400 parts of water, 3 parts of sodium pyrophosphate dispersant, 100 part...

Embodiment 2

[0052] Six-up carbonless copy paper, testing the qualification of the CB and CF sides of the carbonless copy paper in production, and using reference paper to detect the color development of the CB and CF sides of the carbonless copy paper, including the following steps:

[0053] The first step: the preparation of reference paper,

[0054] A, preparation benchmark CB paper: with 500 parts of water, 50 parts of wheat starch spacers, 8 parts of tapioca adhesives, 130 parts of pressure-sensitive melamine formaldehyde resin microcapsules with a solid content of 40%, fatty alcohol polyether defoamer 3 Parts are mixed evenly to make CB paint, and the CB paint is coated at 40g / m 2 On the front side of base paper, the coating weight is 6g / m 2 , cut the coated CB paper into A5 size to make benchmark CB paper;

[0055] B. Preparation of benchmark CF paper: 500 parts of water, 5 parts of sodium pyrophosphate dispersant, 110 parts of 500-purpose kaolin, 60 parts of 500-purpose calcium c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com