Well closing pressure measuring method for low pressure low permeation oil field oil water well

An oil-water well and low-permeability technology, applied in wellbore/well components, measurement, earthwork drilling and production, etc., can solve the problems of long period, shortened oil-water well pressure measurement period, and low data accuracy, so as to achieve reliable results, The effect of shortening the wellbore storage time and shrinking the wellbore storage space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Pressure measurement results of Well Yang 37-17: 2 days of running the test instrument and production, and the shut-in time after the packer was set was 122 hours. It can be seen from the double logarithmic curve stored in the pressure gauge that the test data of the well has been collected completely. Radial flow appeared 40 hours after shutting in the well, and the total logging time was 8 days, while the average testing time of conventional well testing in this block was 15 days. The well test results achieved the expected results.

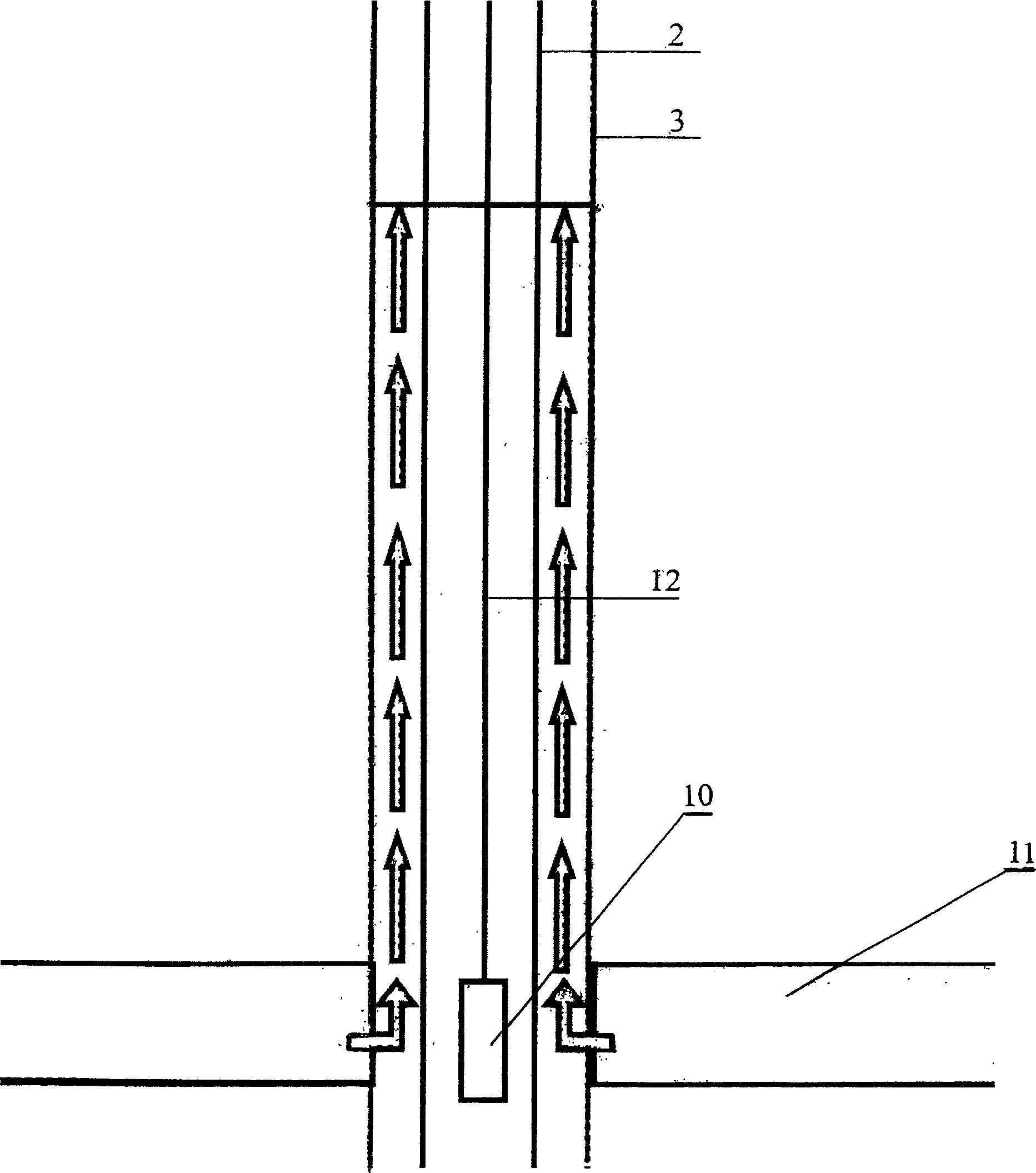

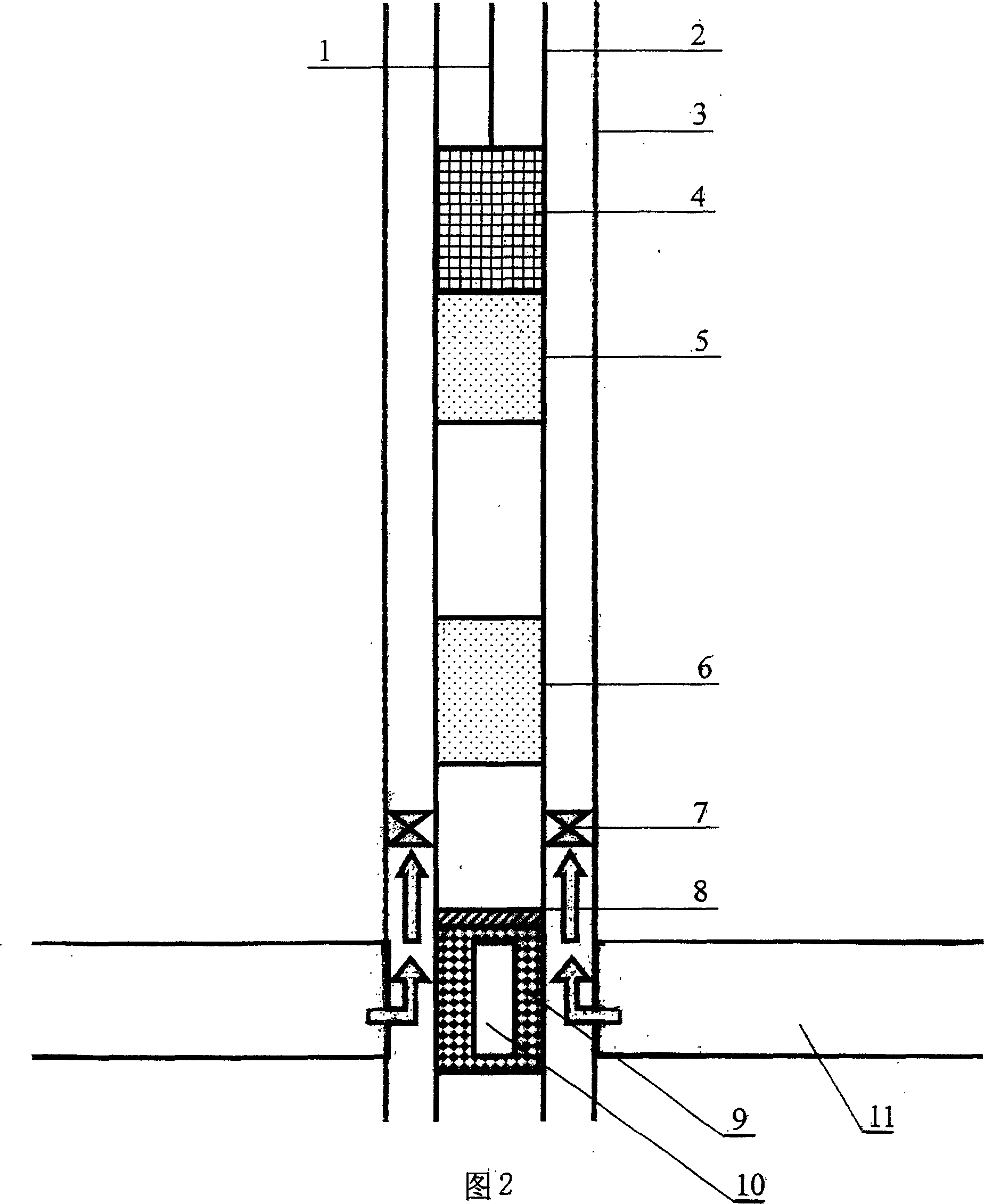

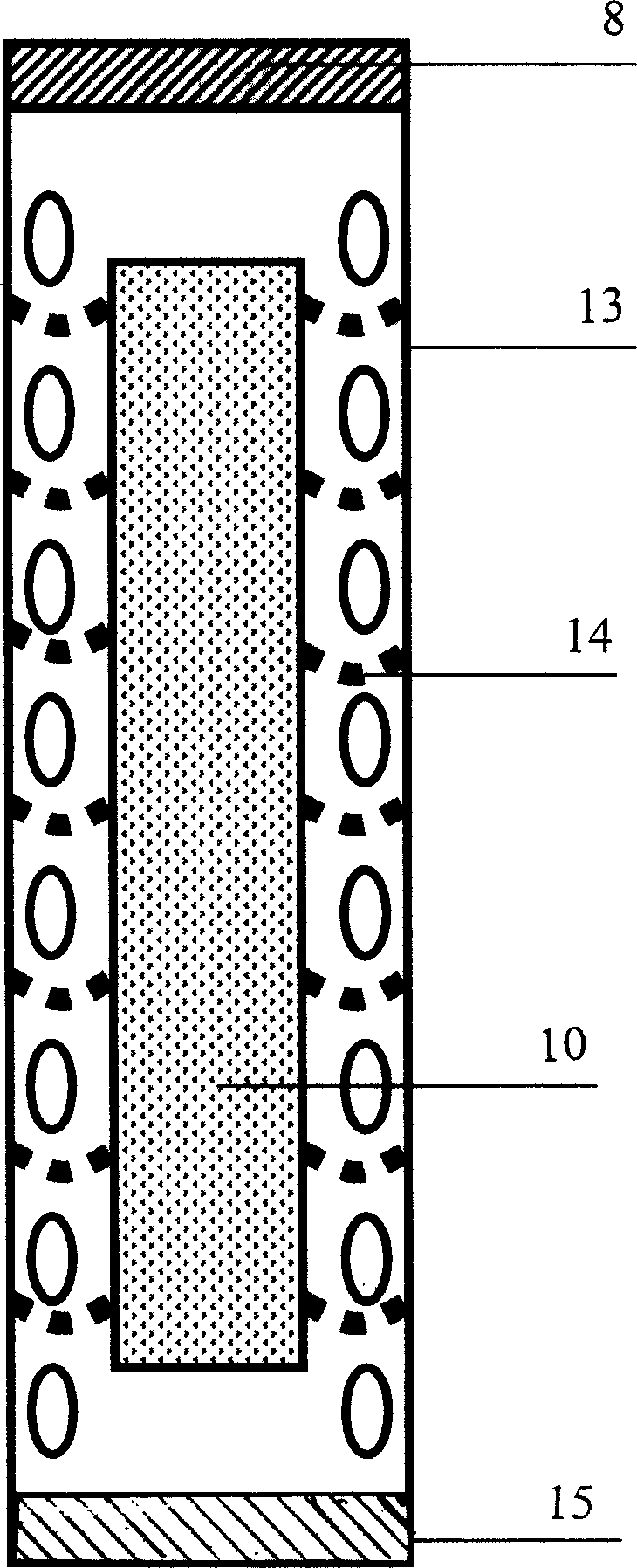

[0028] Yang 37-17 well testing process: refer to attached drawing 2. The reservoir depth is 1046 meters and the thickness is 6.3 meters. First, pull out all production strings in Well Yang 37-17. Next, run into the piezometer string. From bottom to top, the pressure measuring string is oil pipe (2), shockproof tube (9), packer (7), screen pipes (6, 5), oil well pump (4) and sucker rod (1). Pressure gauge (10) is arranged in the shoc...

Embodiment 2

[0031]Pressure measurement results of Well Tian 22-24: From the comparison of pressure double logarithm-derivative curves, it can be seen that the downhole shut-in technology greatly reduces the influence of wellbore storage effect, reduces the continuous flow section, and greatly shortens the test time. The time for directional flow to appear is shortened from 300 hours for conventional well testing to 100 hours, and the average testing time for conventional well testing in this block is 20 days. The test cycle has been greatly reduced.

[0032] The pressure measurement process of Well Tian 22-24 is the same as that of Example 1, and the pipe string structure is the same. The difference is: first, the pressure gauge (10) is lowered into different depths depending on the depth of the reservoir (11). The depth is 1363 meters and the thickness is 14.8 meters. The 2nd, in the 5th step of the pressure measurement process, the time from shutting in the well to pulling out the pres...

Embodiment 3

[0034] Test results in Well 40-31: The average testing time for conventional well testing in this block is 25 days. After 337.5 hours of conventional testing, it is still in the wellbore storage stage, and the pressure rise rate is very slow. However, after shutting down the well, the pressure rises rapidly, and the shape of the curve changes significantly after 170 hours of pressure measurement, and the relevant data can be interpreted by using software.

[0035] The pressure measurement process in Well 40-31 is the same as that in Example 1, and the pipe string structure is the same. The difference is: first, the piezometer (10) is lowered into different depths depending on the depth of the reservoir (11), and the well reservoir (11) ) with a depth of 1605 meters and a thickness of 24.6 meters. The 2nd, in the 5th step of the pressure measurement process, the time from shutting in the well to pulling out the pressure gauge (10) is 6 days. Other pressure measurement process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com