Constant-temperature constant-strain type fiber bragg grating standard device

A fiber grating and standard device technology, applied in the direction of instruments, etc., can solve the problems that the optical fiber grating sensor demodulator cannot be calibrated, and the changing mode is different, so as to achieve the effect of eliminating wavelength drift and eliminating influencing factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

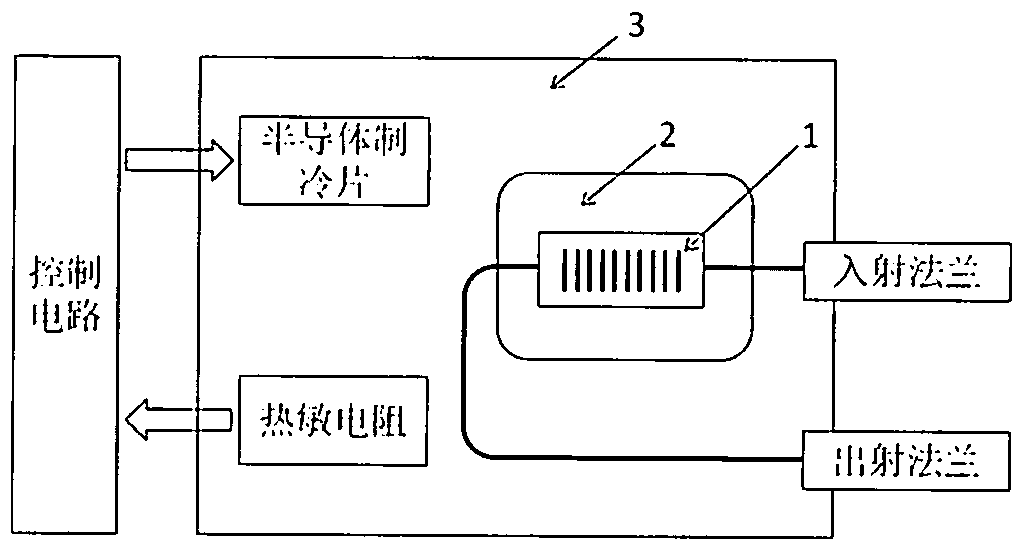

[0012] Such as figure 1 As shown, the constant temperature constant strain type optical fiber grating standard device provided by the present invention includes: optical fiber grating (1), fixed sleeve (2), incident flange, outgoing flange, temperature control substrate (3), semiconductor refrigeration sheet, thermistor and control circuit. The fiber grating 1 is fixed in the fixing sleeve 2, and the fixing sleeve 2 mainly plays the role of protecting the optical fiber and isolating strain, so that the fiber grating (1) works under a constant strain condition. The fixed sleeve (2), the thermistor and the semiconductor refrigeration sheet are fixed on the temperature control substrate (3). The resistance value of the thermistor changes with the temperature, and the temperature information is fed back to the control circuit, and the control circuit adjusts the semiconductor cooling chip to heat up and cool down accordingly, so that the surface temperature on the temperature con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com