Metallized fiber grating stress sensor suitable for cold-rolled sheet shape detection

A technology of stress sensor and optical fiber grating, which is applied in the field of metal cold rolling processing equipment, optical fiber and optical devices, can solve the problems of insufficient stress sensitivity of the sensor, small displacement, and limited application range, etc., so as to expand the applicable range of the equipment and simplify the processing technology , reducing the effect of desensitization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with embodiment the present invention is described in further detail:

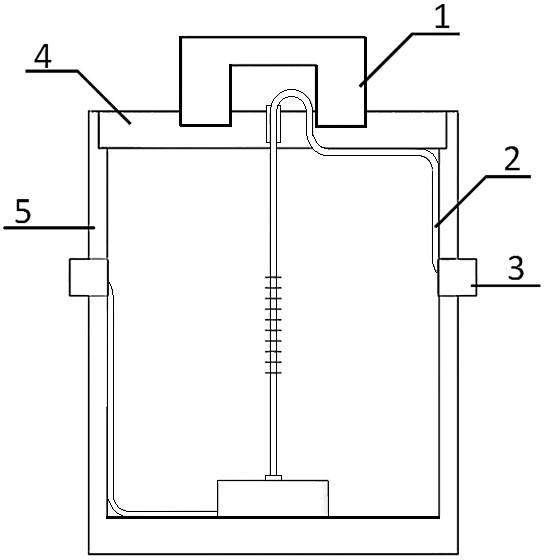

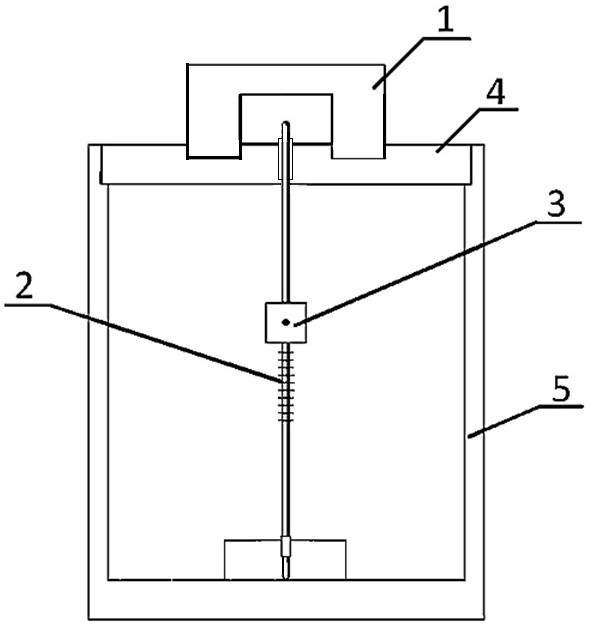

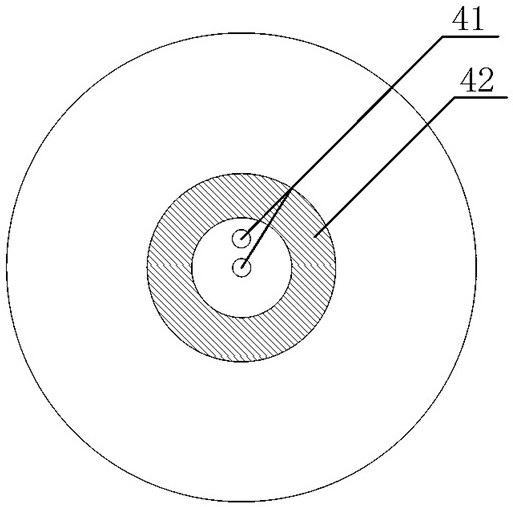

[0028] Such as Figure 1 to Figure 5 As shown, a metallized optical fiber grating stress sensor suitable for cold-rolled sheet shape detection, the sensor of the present invention is a hollow structure, mainly composed of a cylindrical base 5, an elastic metal disc 4, a pressure contact cap 1, and a metallized optical fiber grating 2 and flange joint 3. Such as figure 1 or image 3 or Figure 5 As shown in , the step formed by the cylindrical base outer wall 51 and the cylindrical base inner wall 52 of the cylindrical base 5 can closely accept and fix the elastic metal disc 4; the annular groove 42 on the upper surface of the elastic metal disc 4 It can be tightly fitted with the pressure contact cap 1; the through hole 41 on the elastic metal disc 4 is connected to the through hole 54 in the center of the small cylinder at the bottom of the cylindrical base 5, and the groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com