Relative Horizontal Displacement Sensor Between Layers of Optical Fiber Bragg Grating for Road

A technology of displacement sensor and optical fiber grating, which is applied in the field of displacement sensor, can solve the problems of inability to measure, affect the service life of the road, and make it difficult to move, and achieve the effects of good anti-electromagnetic interference performance, wide application range, and low optical fiber transmission loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings: the present embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation is provided, but the protection scope of the present invention is not limited to the following embodiments.

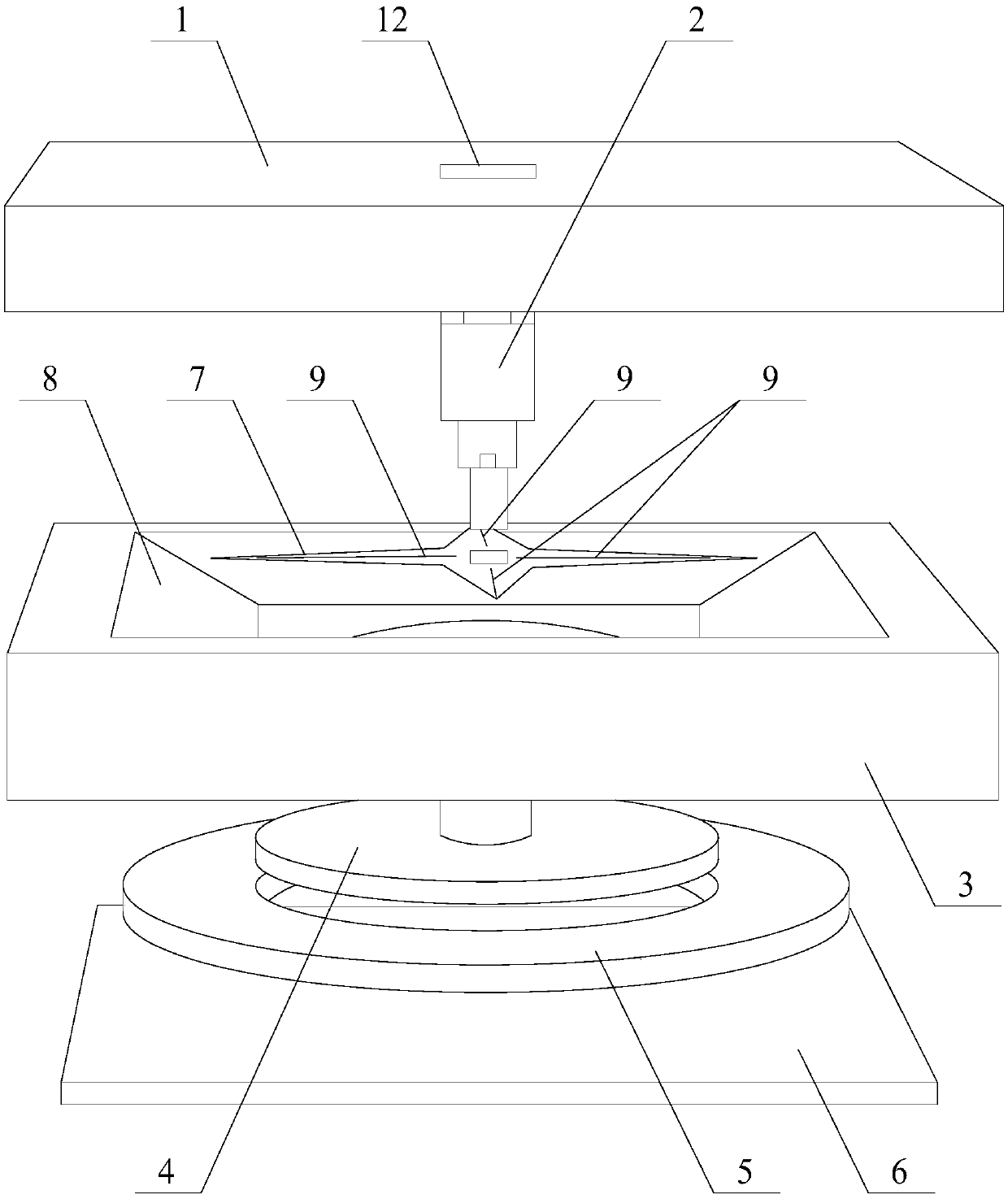

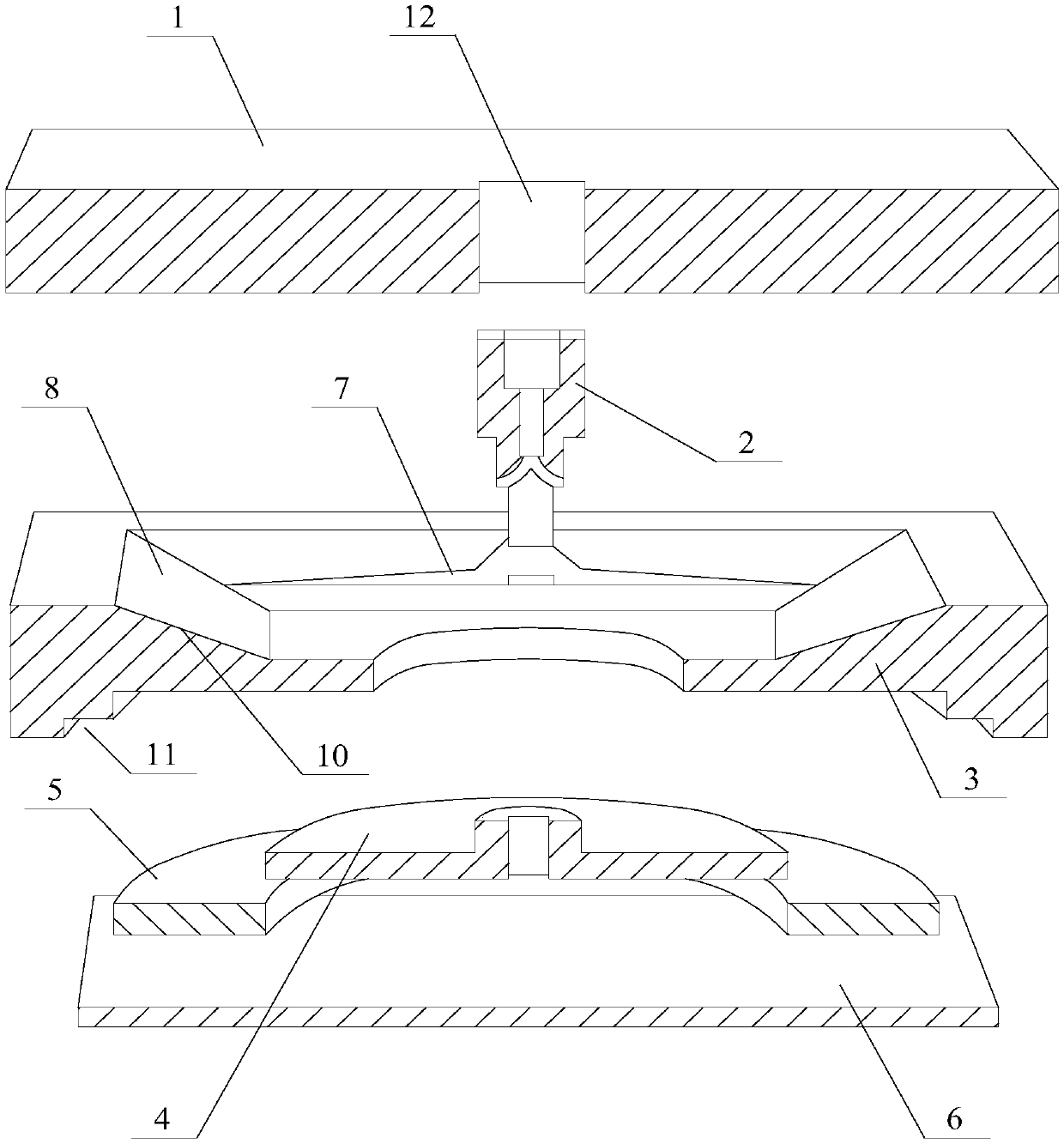

[0020] Such as figure 1 and figure 2 As shown, a relative horizontal displacement sensor between layers of road fiber gratings involved in this embodiment includes: a top cover 1, a central column 2, a bottom plate 3, a fixing ring 4, a silicone pad 5, a fixing plate 6, and equal strength beams 7. Optical fiber grating 9 and glass sheet 10, the bottom of the bottom plate 3 is provided with a fixed plate groove 11, the fixed plate 6 is arranged in the fixed plate groove 11 at the bottom of the bottom plate 3, the upper part of the bottom plate 3 is provided with a chute 8, the chute 8 is provided with a glass sheet 10, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com