Maximum principal stress sensor of road fiber grating

A maximum principal stress, fiber grating technology, applied in instruments, measurement force, measurement of force by measuring the change of optical properties of materials when they are stressed, etc., can solve problems such as single stress and strain measurement, and achieve a wide range of applications, It is convenient for on-site construction and has good insulation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

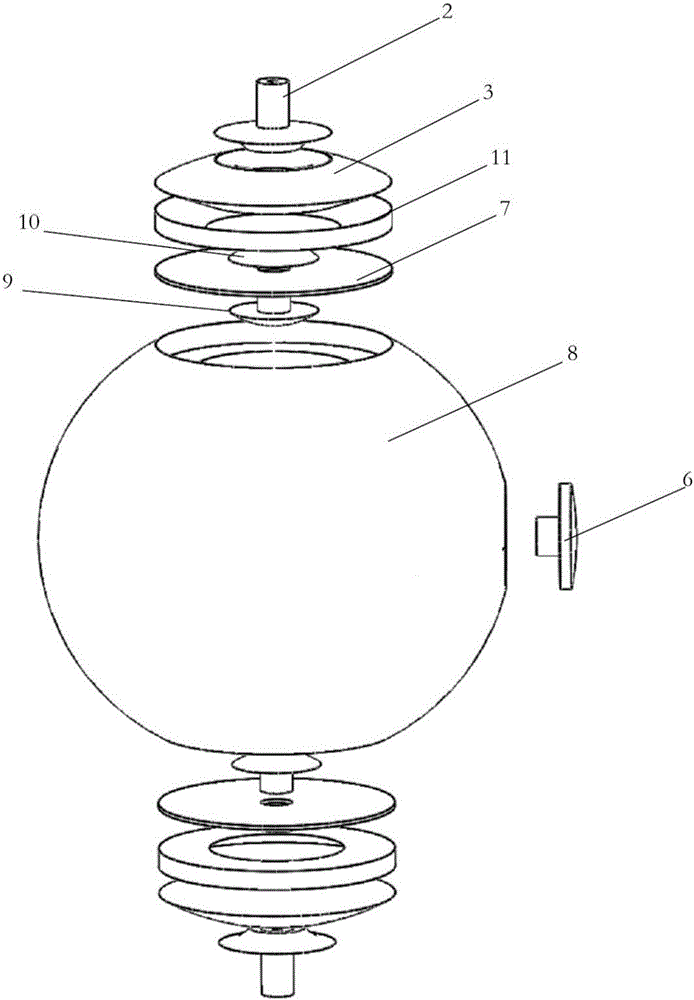

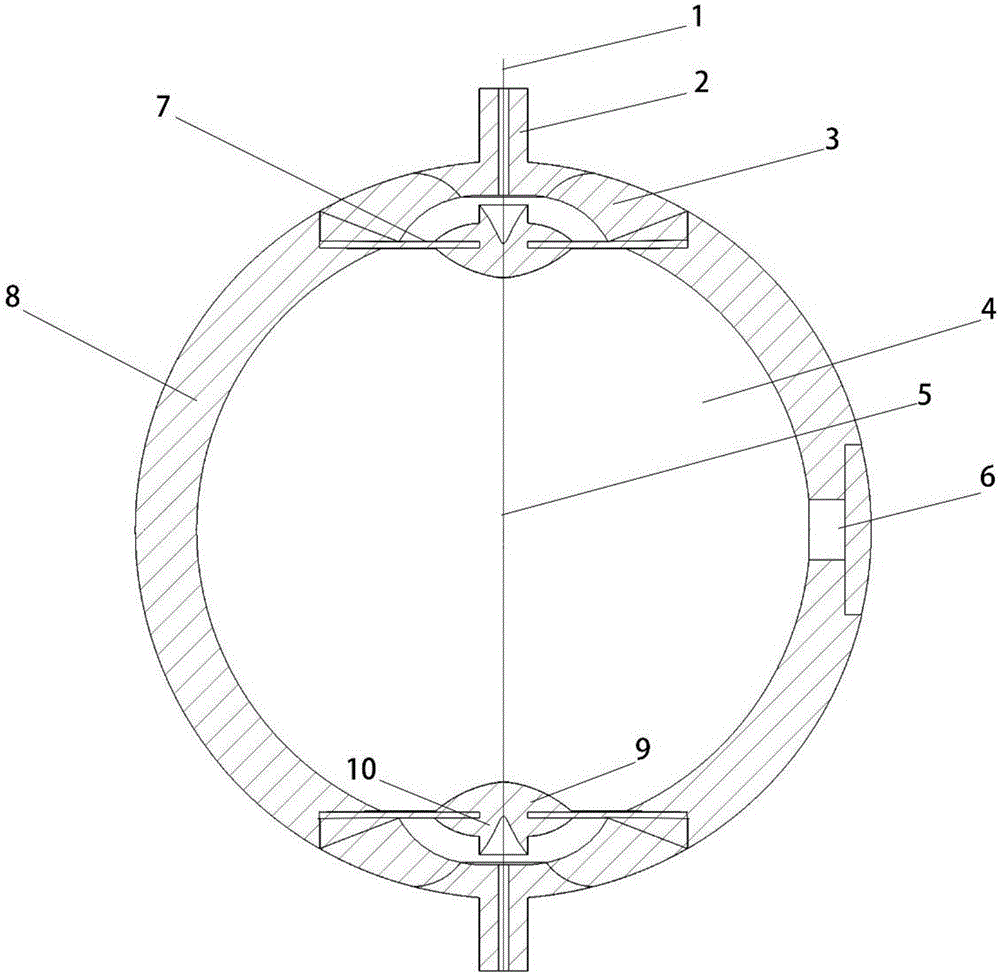

[0023] Depend on figure 1 or figure 2 A fiber grating maximum principal stress sensor for road is shown, which includes a compensating fiber grating 1, a hydraulic chamber 4, a stressed fiber grating 5, an elastic diaphragm 7, a spherical shell 8, an optical fiber fixing ring 9, an optical fiber fixing nail 10, a fixing Ring 11, the two ends of the stressed fiber grating are fixed on the two elastic diaphragms by the fiber fixing ring and the fiber fixing nail, and the external packaging structure of the stressed fiber grating can be added according to actual needs, for example, for some If the structure needs to reduce the test sensitivity, it can be achieved by increasing the package diameter of the middle fiber grating, or increasing the package modulus; similarly, for some structures at low stress levels, when the test sensitivity needs to be increased, it can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com