rotary piston pump

A rotary piston pump and rotary piston technology, applied in the direction of rotary piston pumps, rotary piston machines, rotary piston/swing piston pump components, etc., can solve problems such as wear, loss, and leaky transportation, and achieve Effects of optimized layout, slow moving out movement, and reduced flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

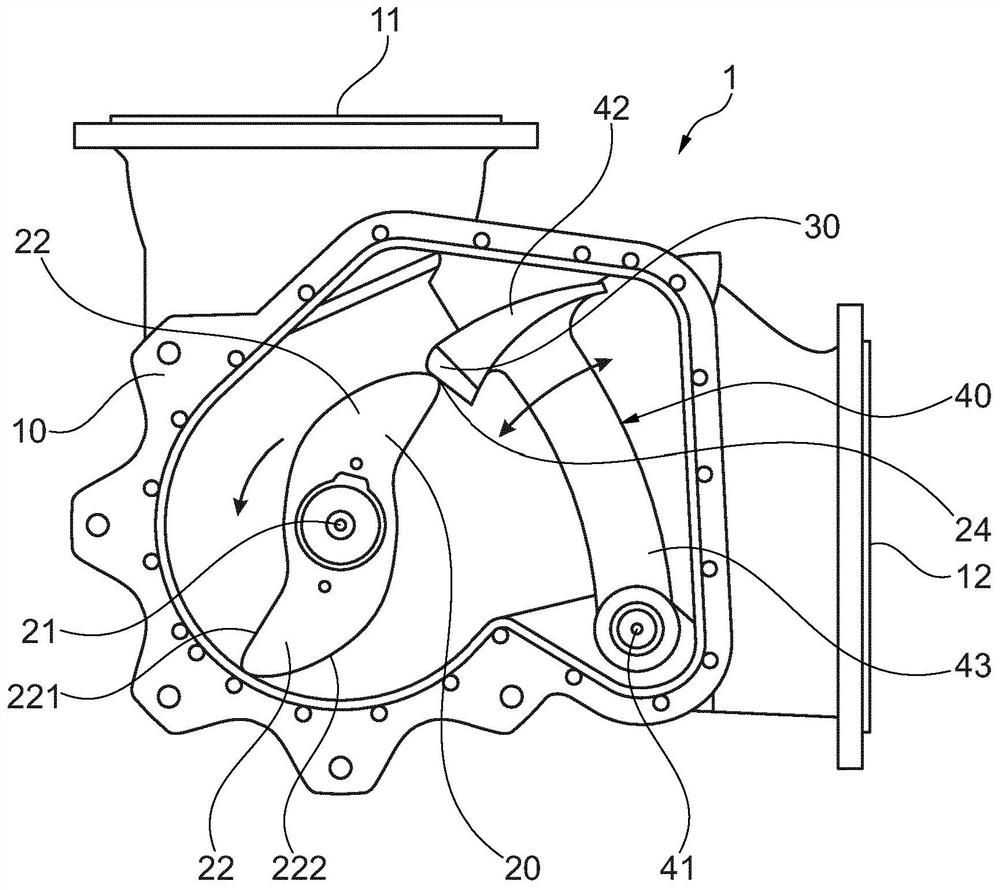

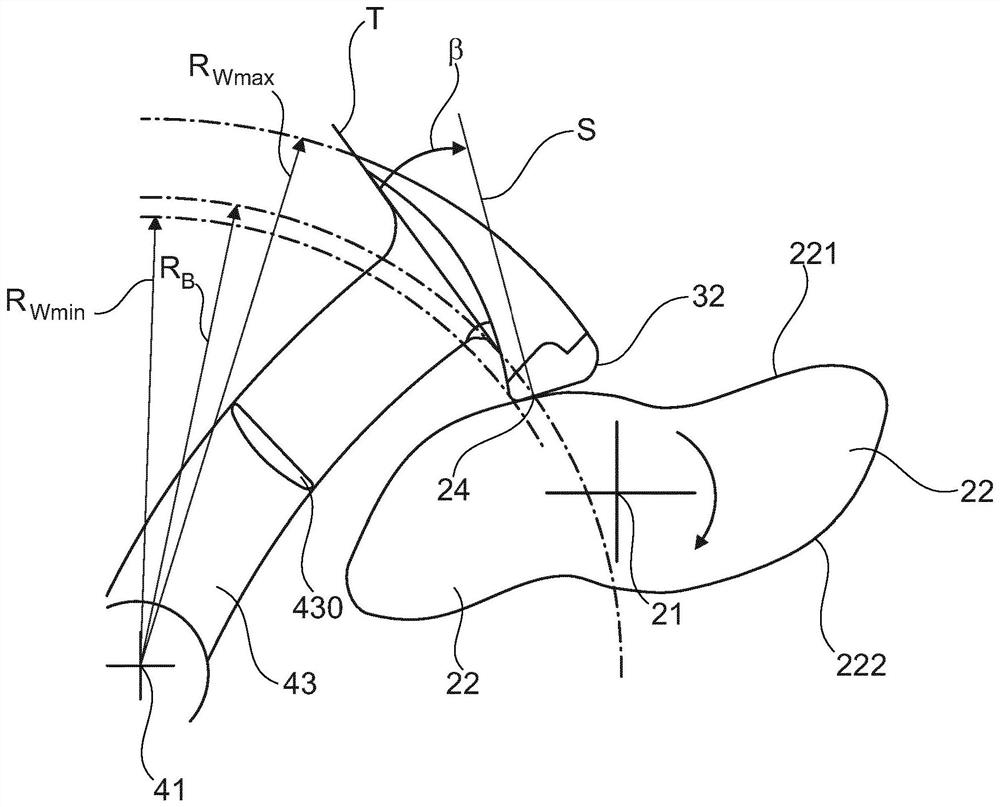

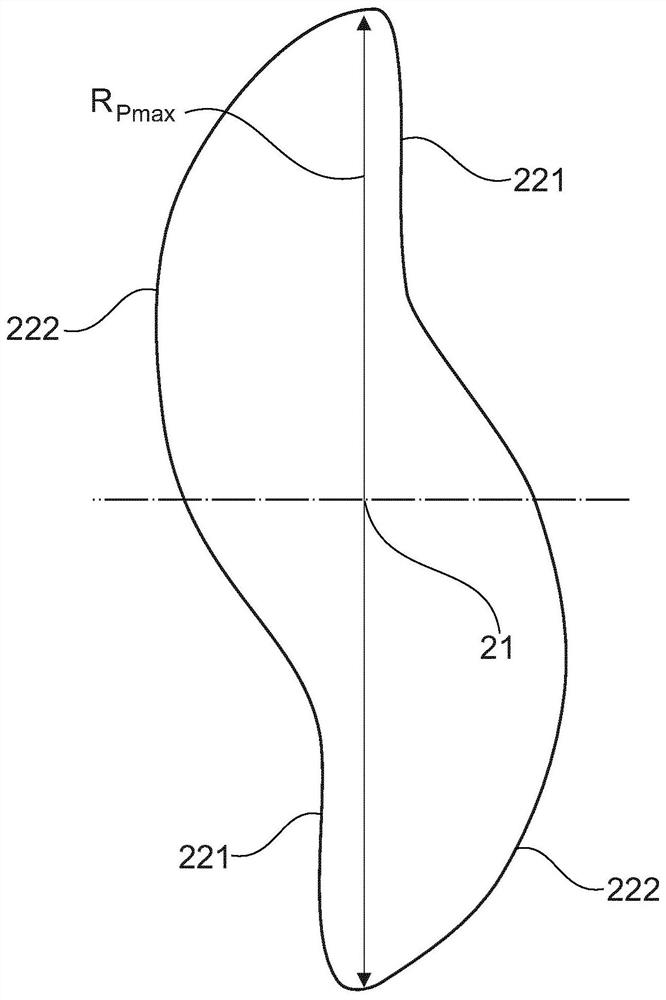

[0030] figure 1 A rotary piston pump 1 is shown in a schematic cross-section with a housing 10 with an inlet 11 on the upper side and an inlet 11 oriented substantially perpendicular to the inlet 11 . figure 1 The outlet 12 is arranged on the right. Inside the housing 10 , the rotary piston 20 is rotatably mounted about a rotational axis 21 . A particularly viscous medium, especially slurries in the production of sugar, is conveyed from the inlet 11 to the outlet 12 by means of a rotary piston 20 which has two transport wings 22 on opposite sides. Here, the rotational direction of the rotary piston 20 is counterclockwise, as indicated by the arrow. The rotary piston 20 with the two transport wings 22 partially rolls on the cylindrical housing wall and forms a separation between the inlet side and the outlet side together with the sealing element 30 and the sealing body 42 of the shut-off wing 40 . During the rotation of the rotary piston 20 it runs on the outer contour of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com