Side-core-pulling injection mold

An injection mold and side core-pulling technology, applied in the field of side-core-pulling injection molds, can solve the problems of inconvenient application, inability to adjust interval time, poor versatility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

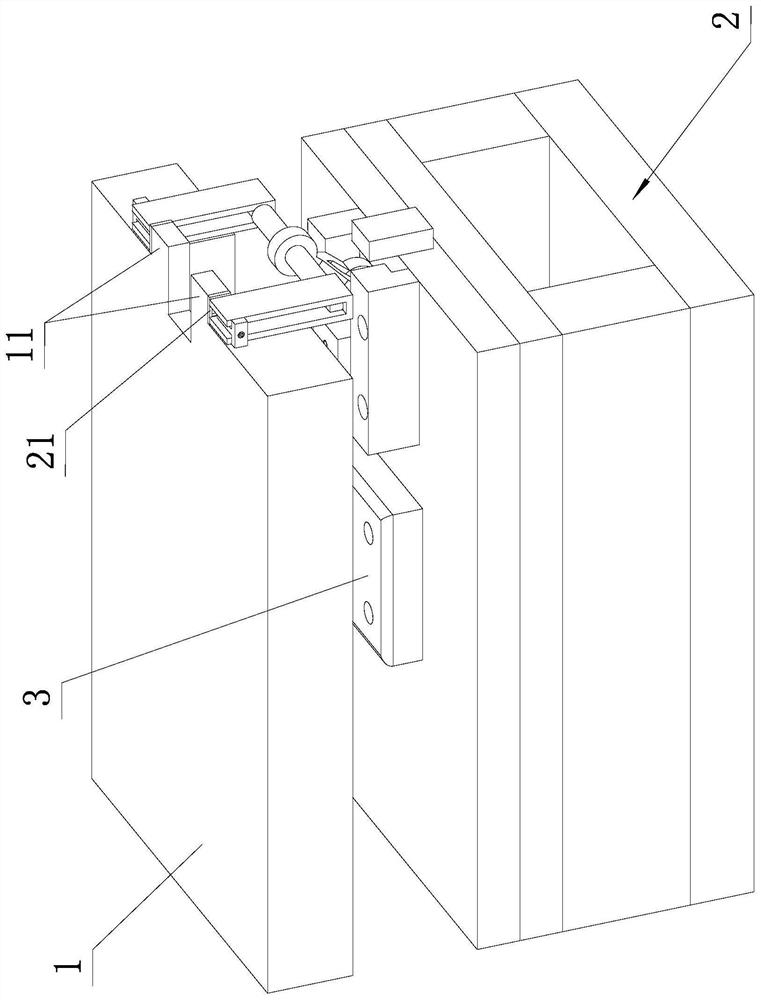

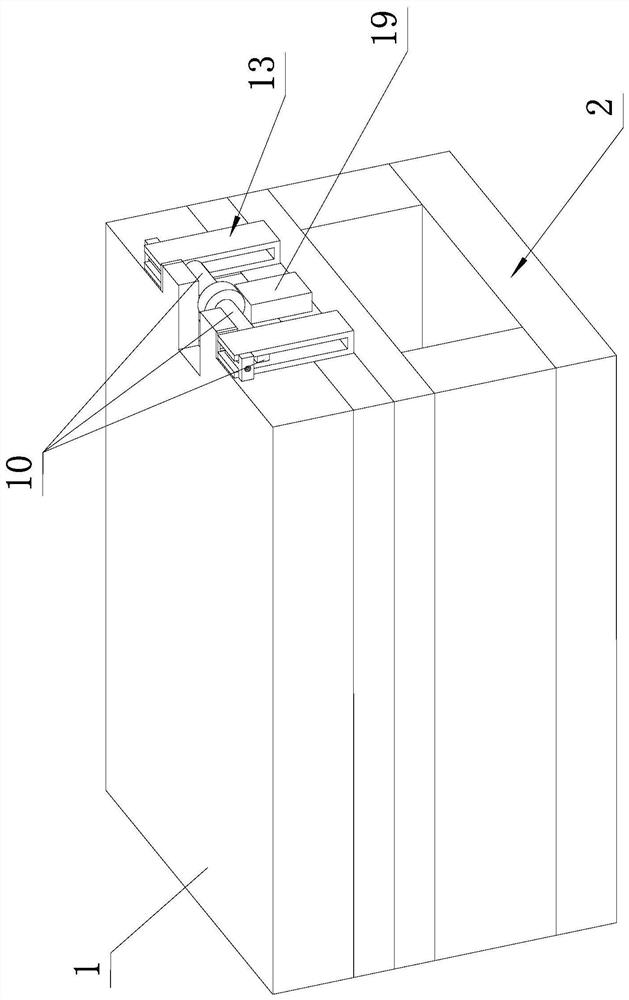

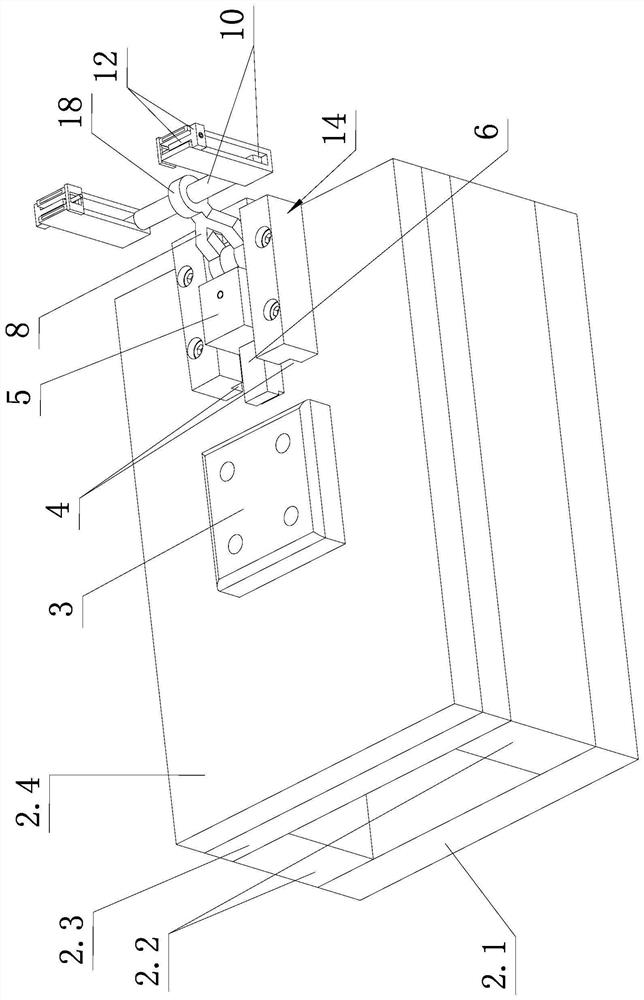

[0024] Such as Figure 1 to Figure 5 As shown, the side core-pulling injection mold of the present invention includes a fixed mold 1 and a movable mold 2, the movable mold 2 is provided with a lower cavity, the lower cavity is fixed with a core 3, and the fixed mold 1 is provided with an upper cavity , after closing the mold, the upper and lower cavities are closed to form a complete cavity. More specifically, the fixed mold is formed by screwing the upper fixed mold seat plate and the lower fixed template, and the upper cavity is located on the lower surface of the fixed template. The movable mold 2 of the present embodiment is formed by screwing the movable mold seat plate 2.1, the spacer 2.2, the backing plate 2.3 and the movable template 2.4 from bottom to top; the core 3 is screwed and fixed on the backing plate 2.3 and the passive templa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com