Bearing pre-tightening device

A technology for bearings and bearing housings, which is applied in the field of bearing preloading, and can solve problems such as lag error, high preloading costs, and poor control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

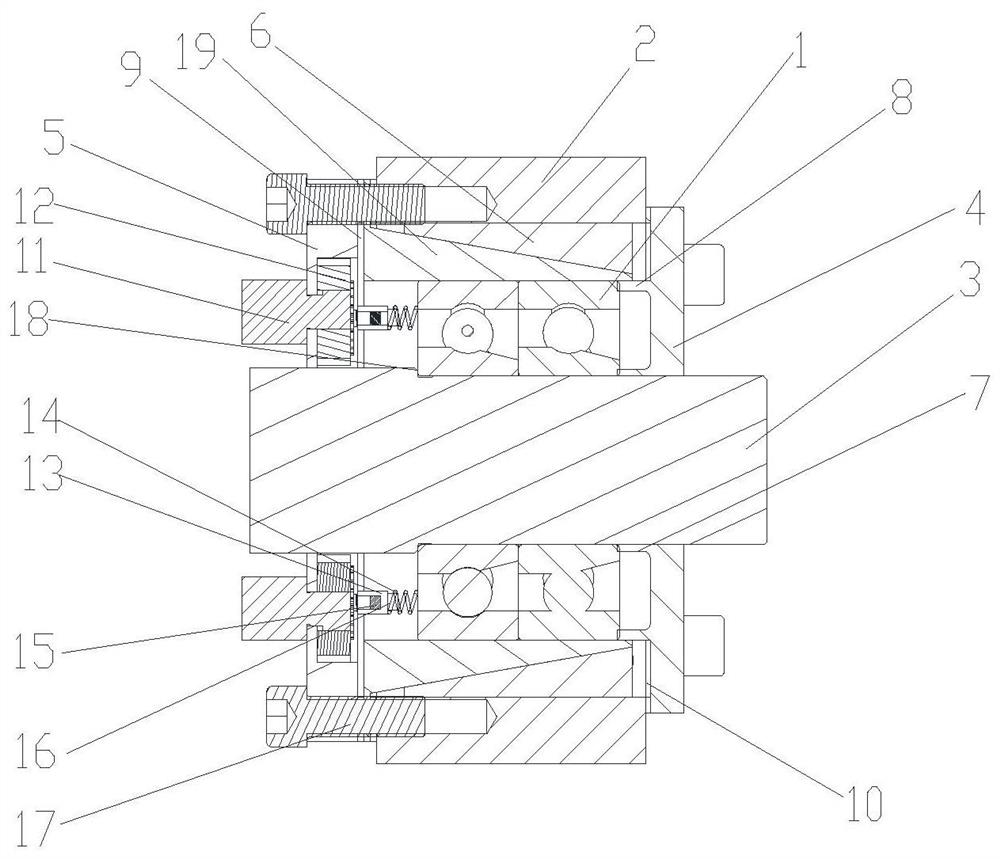

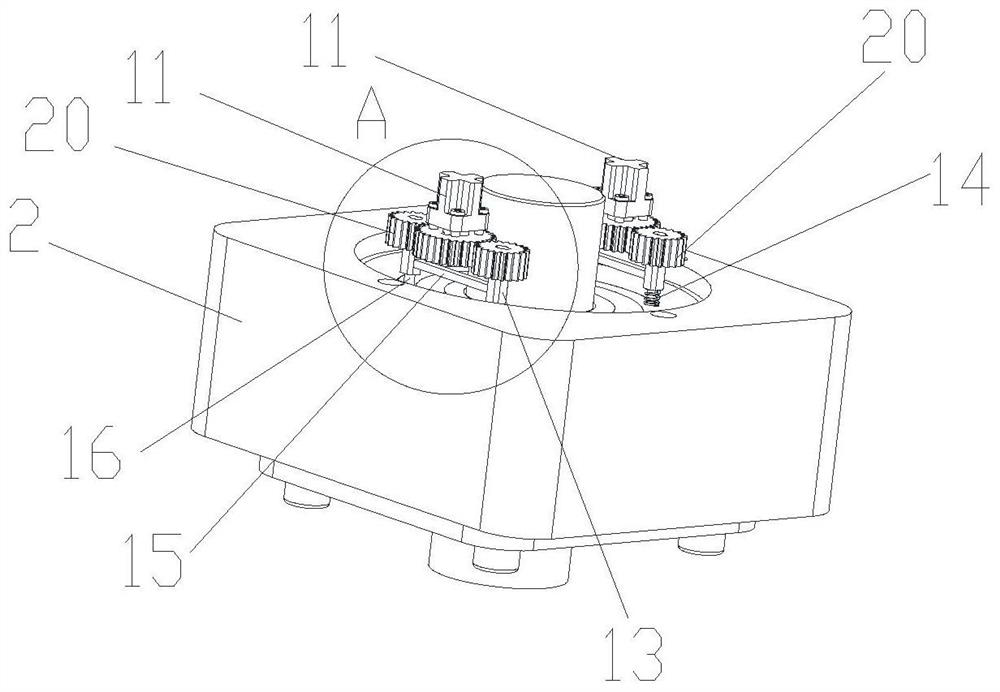

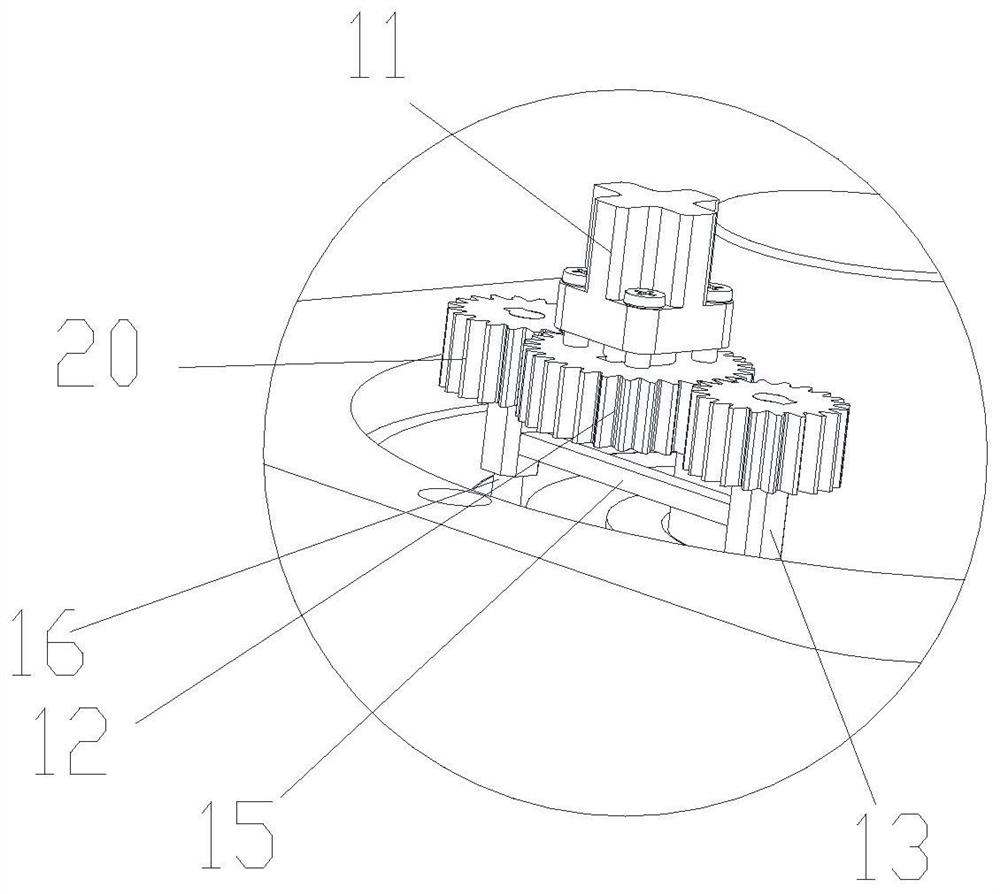

[0021] As shown in the figure, a bearing pretightening device includes a bearing 1, a bearing seat 2, a slanted sleeve 19, a collar 6, a stepped shaft 3 and a cover plate, the inner ring of the bearing 1 is installed in cooperation with the stepped shaft 3, The outer ring of the bearing 1 is installed in interference fit with the inner ring of the slanted sleeve 19, and the outer side of the slanted sleeve 19 is installed in cooperation with the inner ring of the collar 6. The outer surface of the slanted sleeve 19 is tapered, and the The shape of the inner ring of the collar 6 corresponds to the shape of the outer surface of the inclined sleeve 19, the outer ring of the collar 6 is slidably arranged in the bearing seat 2, and the cover plates are fixed on both sides of the bearing seat 2 , the cover plate cooperates with the stepped shaft 3 to axially fix the inner ring of the bearing 1, and the cover plate is also used to resist the outer ring of the bearing 1 near the smalle...

Embodiment 2

[0026] The only difference from the first embodiment above is that the cover plate is divided into a front cover plate 5 and a rear cover plate 4, the front cover plate 5 is located at the larger end of the outer side of the inclined sleeve 19, and the pre-tensioning mechanism is arranged at On the front cover 5, a first protrusion 7 for resisting the inner ring of the bearing 1 is provided on the front cover 5, and a first protrusion 7 for resisting the outer ring of the bearing 1 is provided on the rear cover 4. The second protrusion 8. The rear cover 4 is arranged near the end of the outer surface of the inclined sleeve 19 with a smaller size, the rear cover 4 is provided with a second protrusion 8 for resisting the outer ring of the bearing 1, and the front cover 5 is provided with a first protrusion 7 For resisting the inner ring of the bearing 1 , the step 18 of the stepped shaft 3 is arranged close to the rear cover 4 , and the step 18 of the stepped shaft 3 cooperates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com