Oil cylinder constant-pressure pre-tightening device and method for main bearing of heading machine

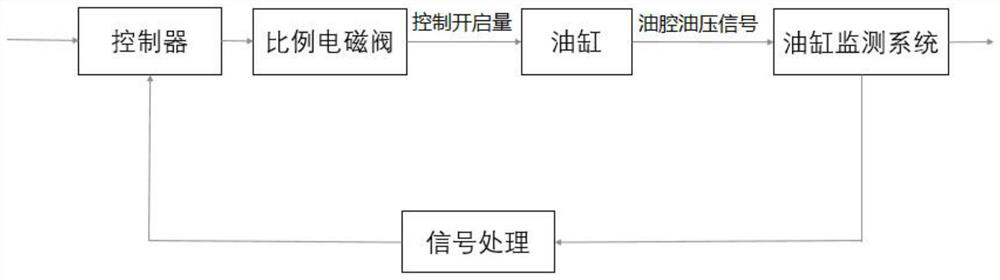

A technology of constant pressure preload and main bearing, applied in the field of roadheader bearings, can solve the problem of unstable working state of the rotating mechanism, and achieve the effects of easy installation and disassembly, simplified structure and high loading accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

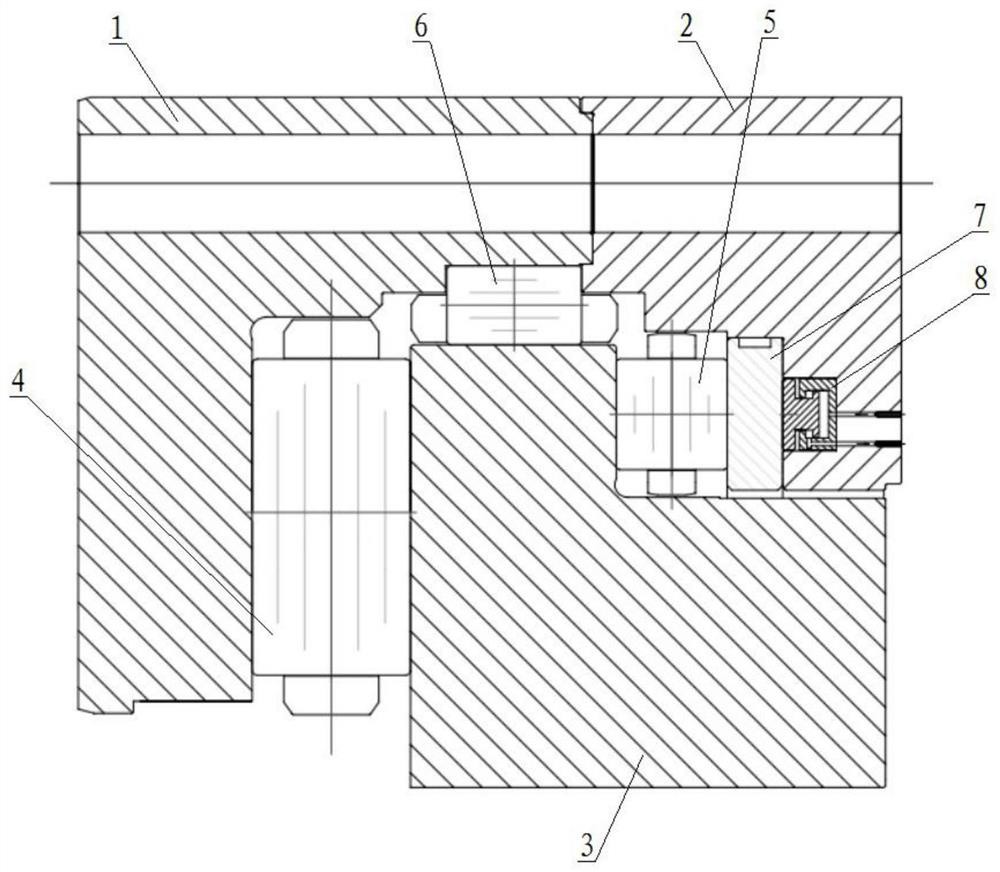

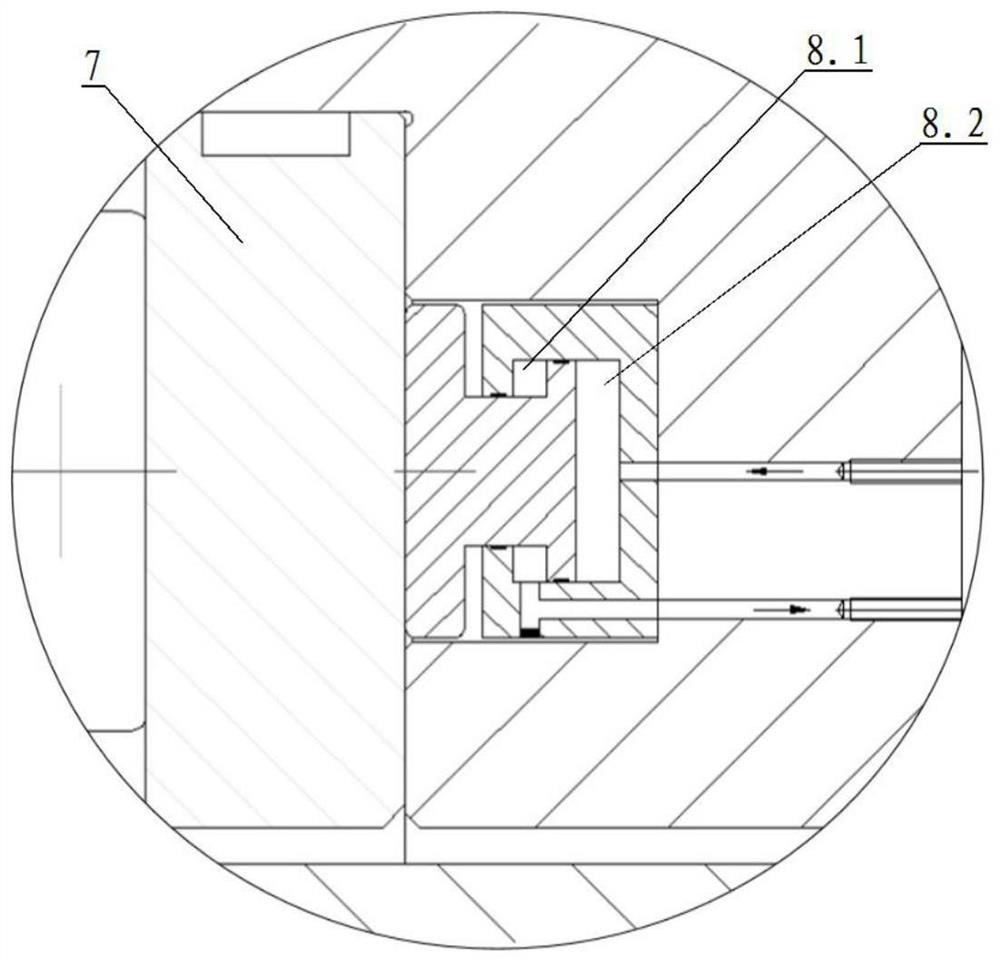

[0026] see Figure 1 ~ Figure 3 , an oil cylinder constant pressure preloading device used on the main bearing of a roadheader, including a floating ring 7 and an oil cylinder 8 .

[0027] The main bearing of the roadheader is in the form of a classic three-row roller bearing, including an inner ring 3 and an outer ring. The outer ring is divided into a first outer ring 1 and a second outer ring 2 in the axial direction, and the second outer ring 2 Compared with the first outer ring 1, which is arranged closer to the working surface (such as the cutter head), the auxiliary thrust roller 5 is arranged between the second outer ring 2 and the inner ring 3, and between the first outer ring 1 and the inner ring 3 The main push roller 4 is set, and the rolling axes of the auxiliary push roller 5 and the main push roller 4 are perpendicular to the central axis of the entire bearing, and a radial roller 6 is also arranged between the outer ring and the inner ring 3, and the radial rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com