A device and method for testing the cooperative bearing performance of an anchor cable system

A test device and technology of anchor cables, applied in the field of collaborative load-bearing performance test devices, can solve problems such as design problems of anchor cable parameters in large-deformation tunnels, achieve convenience in the design of anchor cable parameters, simple structure, and ensure accuracy and accuracy sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

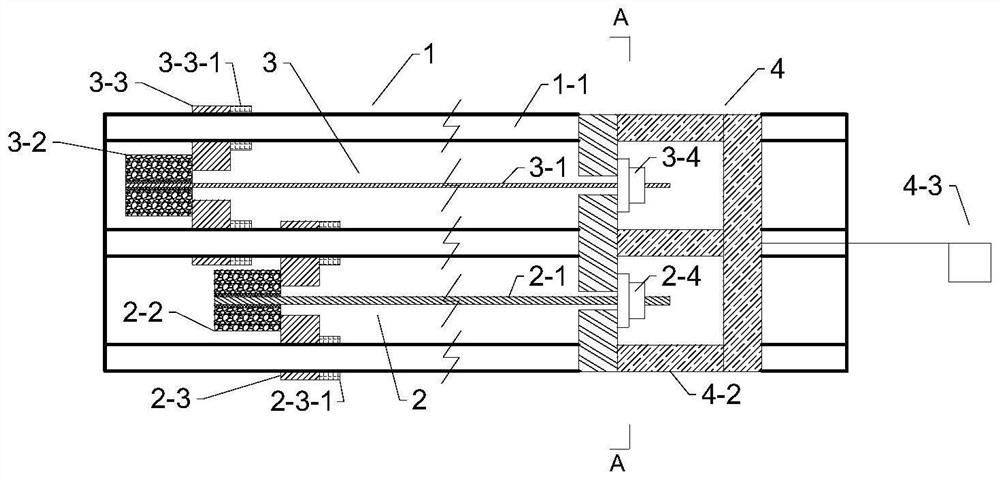

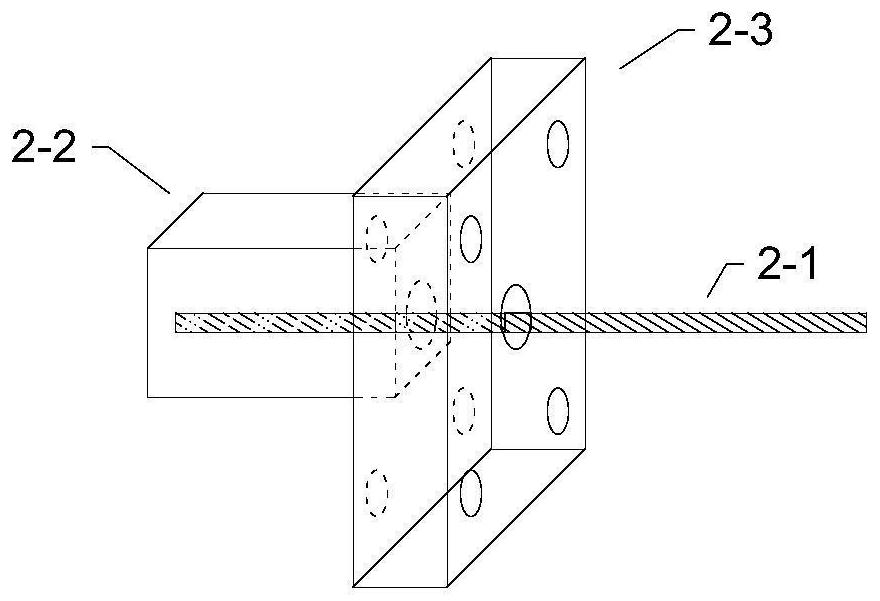

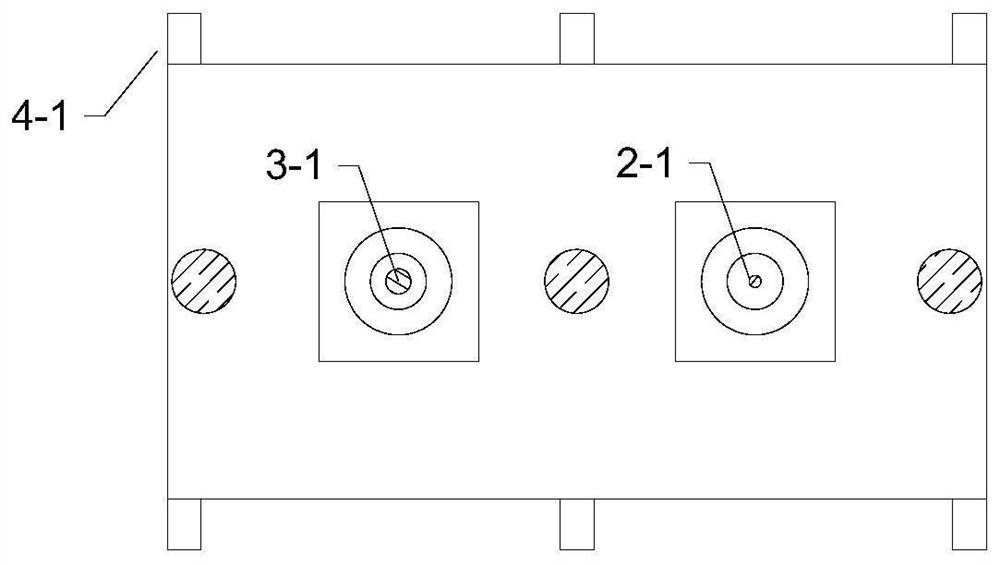

[0043] Embodiment 1, the horizontal spacing of the guide rail 1-1 is 0.5m, the vertical spacing of the guide rail 1-1 is 0.5m, the length of the guide rail 1-1 is 10m, and the rigidity of the guide rail 1-1 is the anchor rod 2-1 and the anchor cable 10 times the rigidity of anchor rod 3-1; the rigidity of anchor rod limiter 2-3 is 10 times that of anchor rod 2-1; the rigidity of anchor cable limiter 3-3 is that of said anchor cable 3-1 10 times the stiffness; the stiffness of the traction frame 4-2 needs to meet the two conditions of 10 times the stiffness of the anchor rod 2-1 and more than 10 times the stiffness of the anchor cable 3-1.

[0044] In specific implementation,

[0045] 1) A tunnel support is designed with a bolt length of 2.6m, a diameter of 25mm, and an anchorage length of 1.8m, using a 150×150×8mm butterfly tray with a pre-tightening force of 80kN; an anchor cable length of 6.3m, a diameter of 17.8mm, and an anchorage length of 1.7 m, preload 100kN. Comparin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com