Cosmetic

A technology for cosmetics and volatile oil, applied in the field of cosmetics, can solve the problems of difficult-to-emulsify cosmetics and the like, and achieve the effects of excellent coating and finishing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

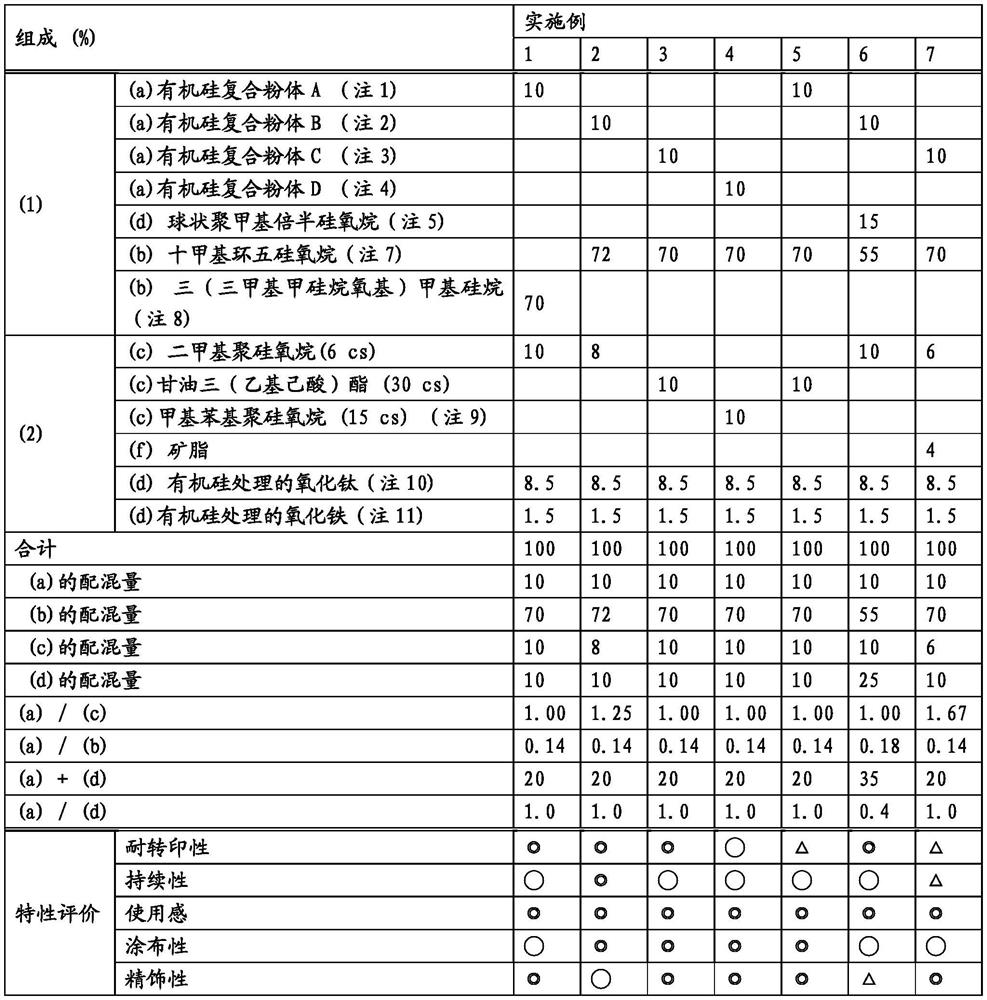

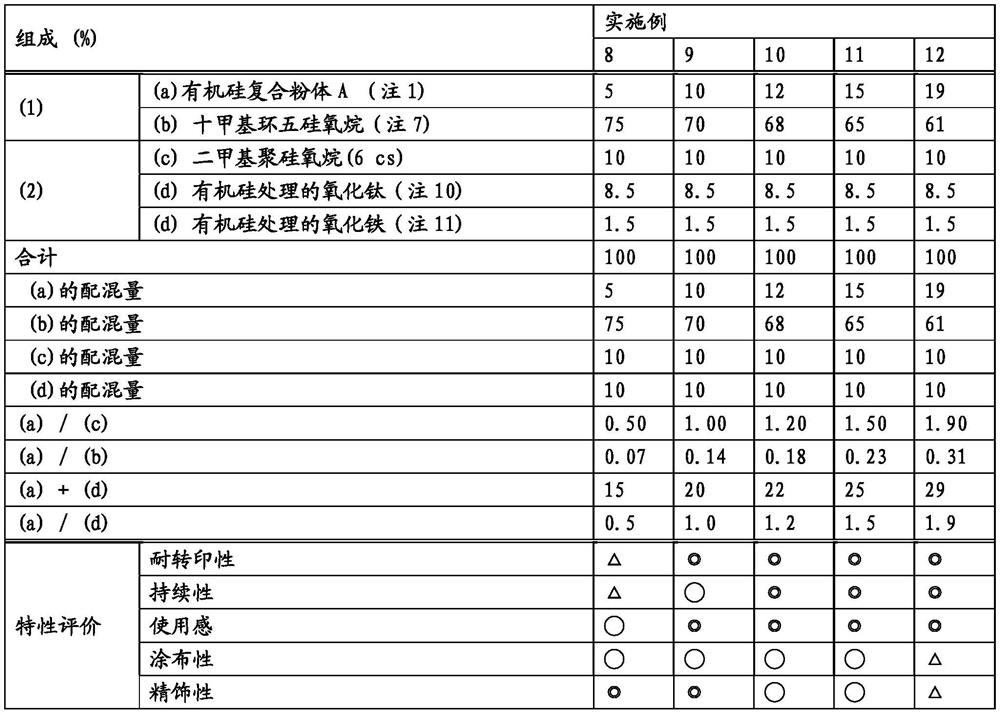

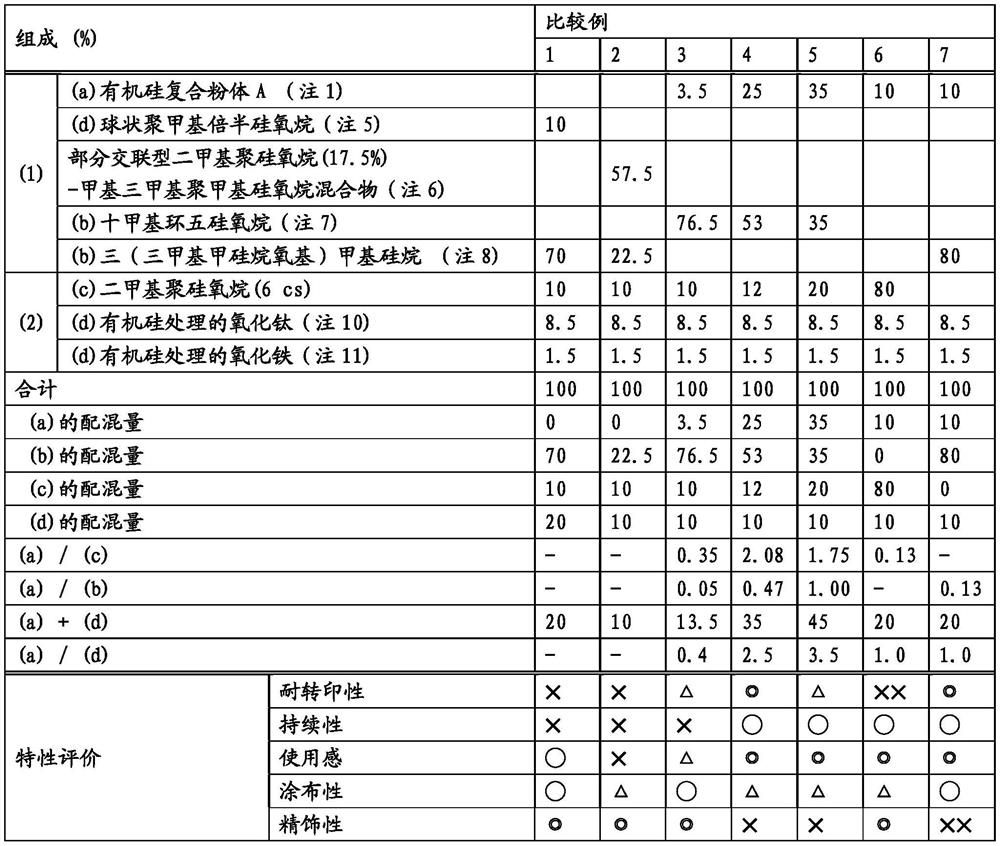

Embodiment 1~12

[0117]

[0118] A: Component (2) was uniformly mixed with 3 rollers.

[0119] B: A was added to component (1), and mixed uniformly to obtain a non-aqueous foundation.

[0120]

[0121] A: Component (2) was uniformly mixed with DISPER.

[0122] B: Add A to component (1), and mix uniformly.

[0123] C: Component (3) was added to B and emulsified to obtain a water-in-oil type foundation.

[0124] (1) Characteristic evaluation

[0125] For the cosmetics of Examples and Comparative Examples, a panel of 10 people evaluated the transfer resistance of the cosmetics (they do not adhere to the face towel when wiped with a towel after 20 minutes of application), and the durability (the cosmetics are not attached to the towel after 3 hours of application). Appearance), use feeling (not sticky), coating properties (good spreadability), finishing properties (no floating, powdery, excessive dry feeling). Evaluation was performed based on the evaluation criteria shown in Table 1, and ...

Embodiment 20

[0172] oil foundation

[0173]

[0174] A: Components 1-4 are uniformly mixed.

[0175] B: Components 12 to 17 were uniformly mixed with a roller.

[0176] C: Add components 5-11 to A, and mix uniformly.

[0177] D: Add B to C and mix uniformly to obtain an oil foundation.

[0178]

[0179] Compounding amount of (a): 14.0%

[0180] (a) / (c): 1.56

[0181] (Note 1) KSP-411 (manufactured by Shin-Etsu Chemical Co., Ltd.)

[0182] (Note 2) KF-6038 (manufactured by Shin-Etsu Chemical Co., Ltd.)

[0183] (Note 3) KP-545 (manufactured by Shin-Etsu Chemical Co., Ltd.)

[0184] (Note 4) KF-9021 (manufactured by Shin-Etsu Chemical Co., Ltd.)

[0185] (Note 5) AEROSIL R972 (manufactured by Japan AEROSIL Co., Ltd.)

[0186] (Note 6) KF-6106 (manufactured by Shin-Etsu Chemical Co., Ltd.)

[0187] (Note 7) KF-56A (manufactured by Shin-Etsu Chemical Co., Ltd.)

[0188] (Note 8) Use KF-9901 (manufactured by Shin-Etsu Chemical Co., Ltd.) to perform hydrophobic surface treatment o...

Embodiment 21

[0191] Casting Foundation (Solid Foundation)

[0192]

[0193] A: Components 7 to 12 were uniformly mixed with a roller.

[0194] B: Components 1 to 6 were uniformly mixed at 85°C.

[0195] C: A was added to B, and it mixed uniformly, and it filled in the mold at 80 degreeC, and obtained the casting foundation.

[0196]

[0197]

[0198] Compounding amount of (a): 18.0%

[0199] (a) / (c): 1.88

[0200] (Note 1) KSP-101 (manufactured by Shin-Etsu Chemical Co., Ltd.)

[0201] (Note 2) KMP-590 (manufactured by Shin-Etsu Chemical Co., Ltd.)

[0202] (Note 3) KF-6038 (manufactured by Shin-Etsu Chemical Co., Ltd.)

[0203] (Note 4) KSG-19 (manufactured by Shin-Etsu Chemical Co., Ltd.)

[0204] (Note 5) KF-56A (manufactured by Shin-Etsu Chemical Co., Ltd.)

[0205] (Note 6) KF-6105 (manufactured by Shin-Etsu Chemical Co., Ltd.)

[0206] (Note 7) AES-3083 (manufactured by Shin-Etsu Chemical Co., Ltd.) was used to treat the surface of the powder with hydrophobization. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oil absorption | aaaaa | aaaaa |

| oil absorption | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com