Quick-brewing constant-temperature feeding bottle and powder storage box

A feeding bottle and constant temperature technology, applied to feeding bottles, bottle/can parts, clothing, etc., can solve the problems of concave surface of the flexible sleeve, troublesome operation, difficult to clean, etc., achieve rapid heating, easy to carry, and prevent burns Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

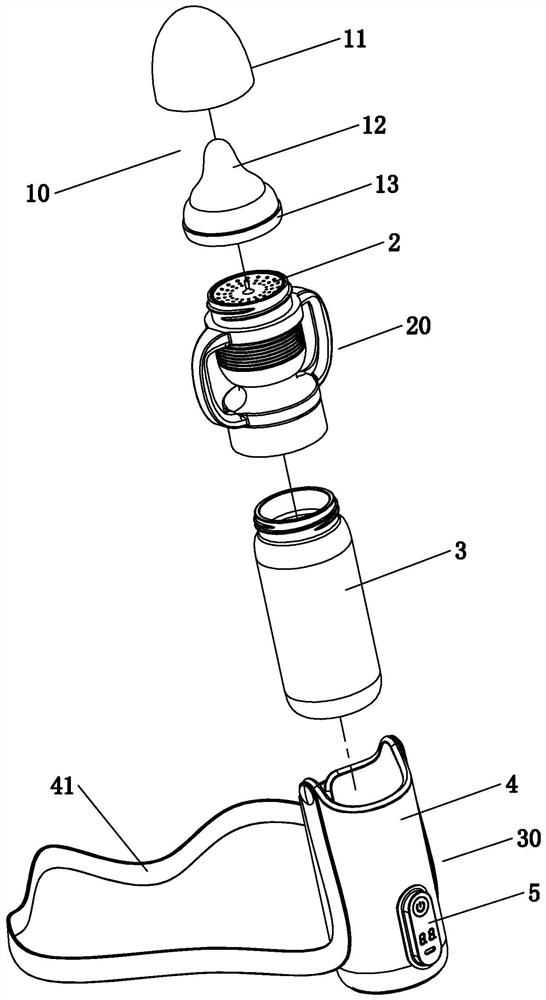

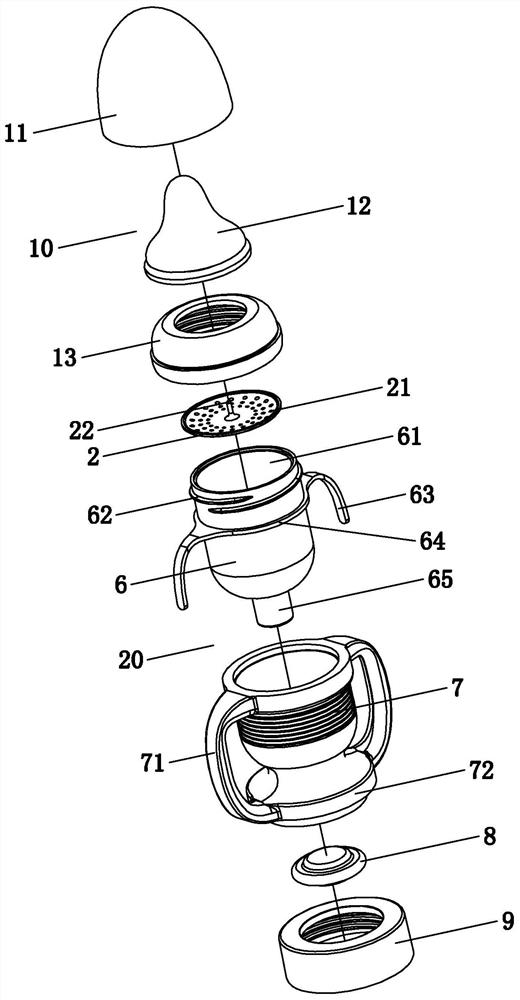

[0041] Embodiment one, see Figure 1 to Figure 9 As shown, a quick flushing constant temperature feeding bottle includes a heating bottle cover, a feeding bottle and a powder storage box 20, the heating bottle cover includes a bottle cover body 4, a heating element and a control module 5, the heating element and the control module 5 are electrically connected, and the heating element And the control module 5 is arranged on the bottle cover body 4, the feeding bottle includes a bottle body 3 and a cover body assembly 10, the powder storage box 20 is arranged between the bottle body 3 and the cover body assembly 10, and the bottle body 3 is arranged on the bottle cover body 4; the powder storage box 20 includes a powder storage box body 6 and a sealing plug 8. A powder storage bin 61 is arranged inside the powder storage box body 6. The top of the powder storage bin 61 is open and connected to the cover assembly 10. The powder storage box The bottom of the main body 6 is provide...

Embodiment 2

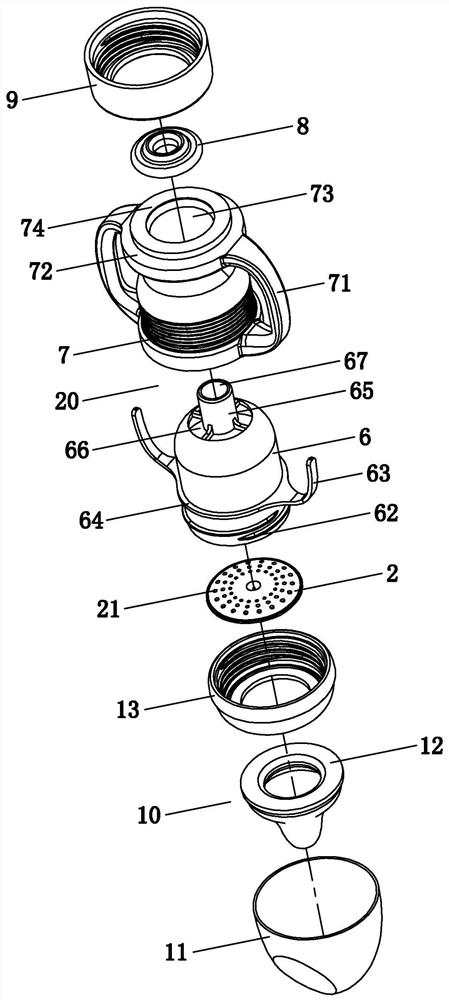

[0055] Embodiment two, see Figure 10 to Figure 14 As shown, a powder storage box 20 includes a powder storage box body 6, a cover assembly 10 and a sealing plug 8. A powder storage bin 61 is arranged inside the powder storage box body 6. The top of the powder storage bin 61 is open and integrated with the cover body. The bottom of the powder storage box body 6 is provided with a powder outlet 73, the powder outlet 73 communicates with the outside world and the powder storage bin 61, the sealing plug 8 is arranged in the powder outlet 73, and is sealed with the powder outlet 73 An elastic compression sleeve 72 is provided between the bottom of the powder storage box body 6 corresponding to the powder storage bin 61 and the powder outlet 73 , and the inner side of the elastic compression sleeve 72 is provided with a push rod 65 , and the push rod 65 points to the sealing plug 8 .

[0056] The upper end of the ejector rod 65 is connected to the bottom of the powder storage bin 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com