Planar transformers, power converters and circuit boards

A planar transformer and circuit board technology, applied in the direction of transformer/inductor coil/winding/connection, transformer/inductor components, circuits, etc., can solve the problem of difficulty in obtaining common mode current suppression effect, and achieve the best EMI performance , The effect of suppressing common mode current and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

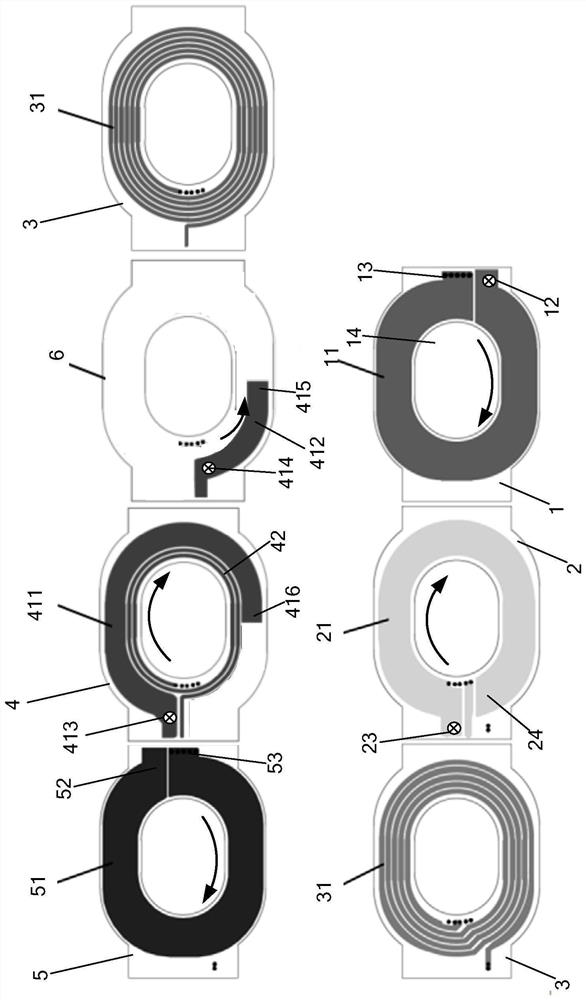

[0028] Such as figure 1 and 2 As shown, an embodiment of the planar transformer of the present invention is a secondary primary secondary structure, which includes a secondary coil layer 1, a shielding layer 2, and a plurality of primary coil layers 3 that are all located on the PCB board from bottom to top. , shielding layer 6, shielding layer 4 and secondary coil layer 5, the planar transformer is also provided with secondary static point end 12 and secondary moving point end 52, shielding layer 4 and shielding layer 6 are arranged on secondary coil layer 5 and primary Between the coil layers 3 , the shielding layer 2 is arranged between the secondary coil layer 1 and the primary coil layer 3 .

[0029] The secondary coil layer 1 includes the secondary coil 11, the secondary coil layer 5 includes the secondary coil 51, the shielding layer 2 includes the shielding coil 21, the shielding layer 4 includes a first shielding coil section 411 of N1 turns, and the shielding layer ...

Embodiment 2

[0040] Another preferred embodiment of the planar transformer of the present invention, it and figure 2 The embodiment is basically the same, the main differences include: the position of the shielding layer 2 is placed between the secondary coil layer 5 and the primary coil layer 3, and the shielding layer 4 and the shielding layer 6 are placed between the secondary coil layer 1 and the primary coil layer between 3.

[0041] In addition, the shielding layer 4 and the shielding layer 6 of this embodiment do not have an auxiliary coil, but the shielding layer 2 has an auxiliary coil.

[0042] The planar transformer designed by the present invention is suitable for an adapter or a charger whose output voltage is 5V-24V, or outputs a fixed voltage (5V / 12V / 15V / 19V / 20V / 24V) within this voltage range, or a variable voltage ( 5V-9V / 5V-11V / 5V-12V / 5V-15V / 5V-20V) power converter, adapter or charger.

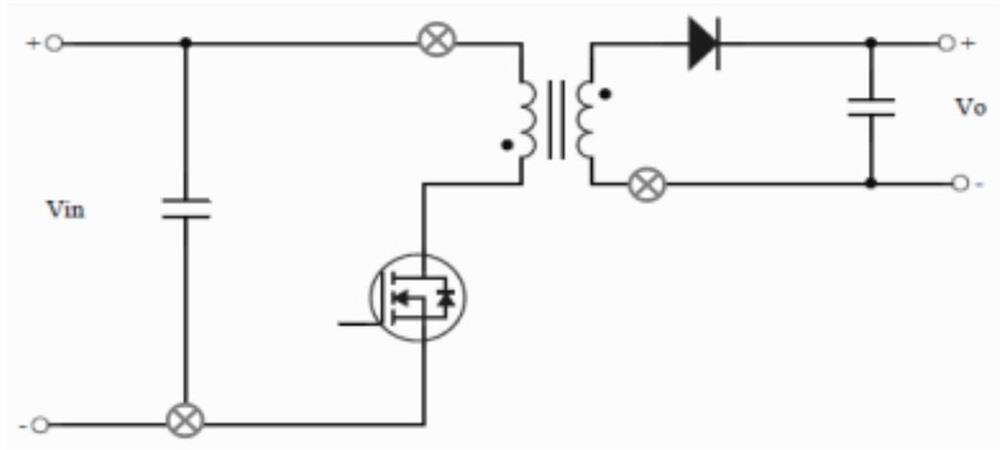

[0043] The present invention also provides a circuit board with a power conversion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com