Threshold calculation with weight

一种阈值、计算机的技术,应用在计算、计算机零部件、永久直观显示的装置等方向,能够解决无法发现印刷产品、变化、印刷结果质量变化等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

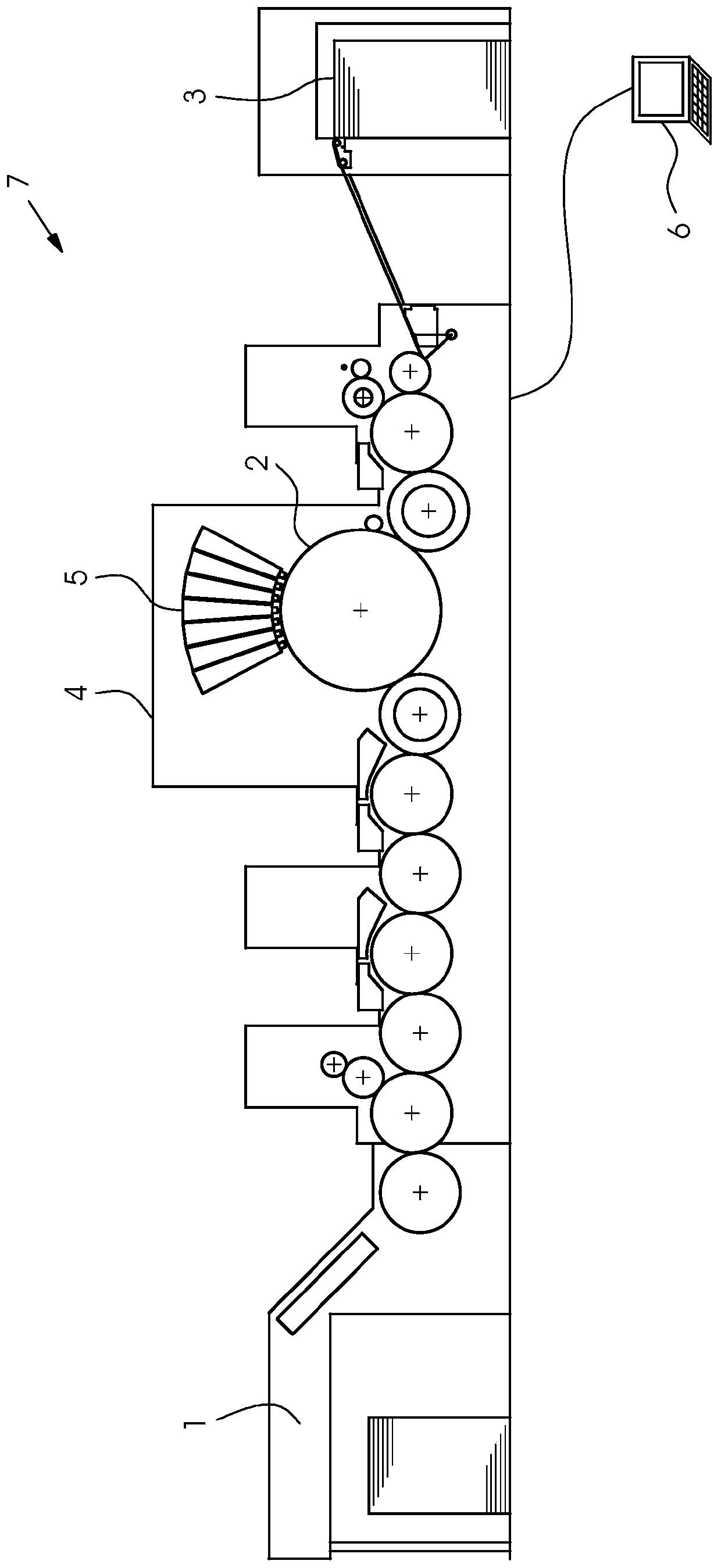

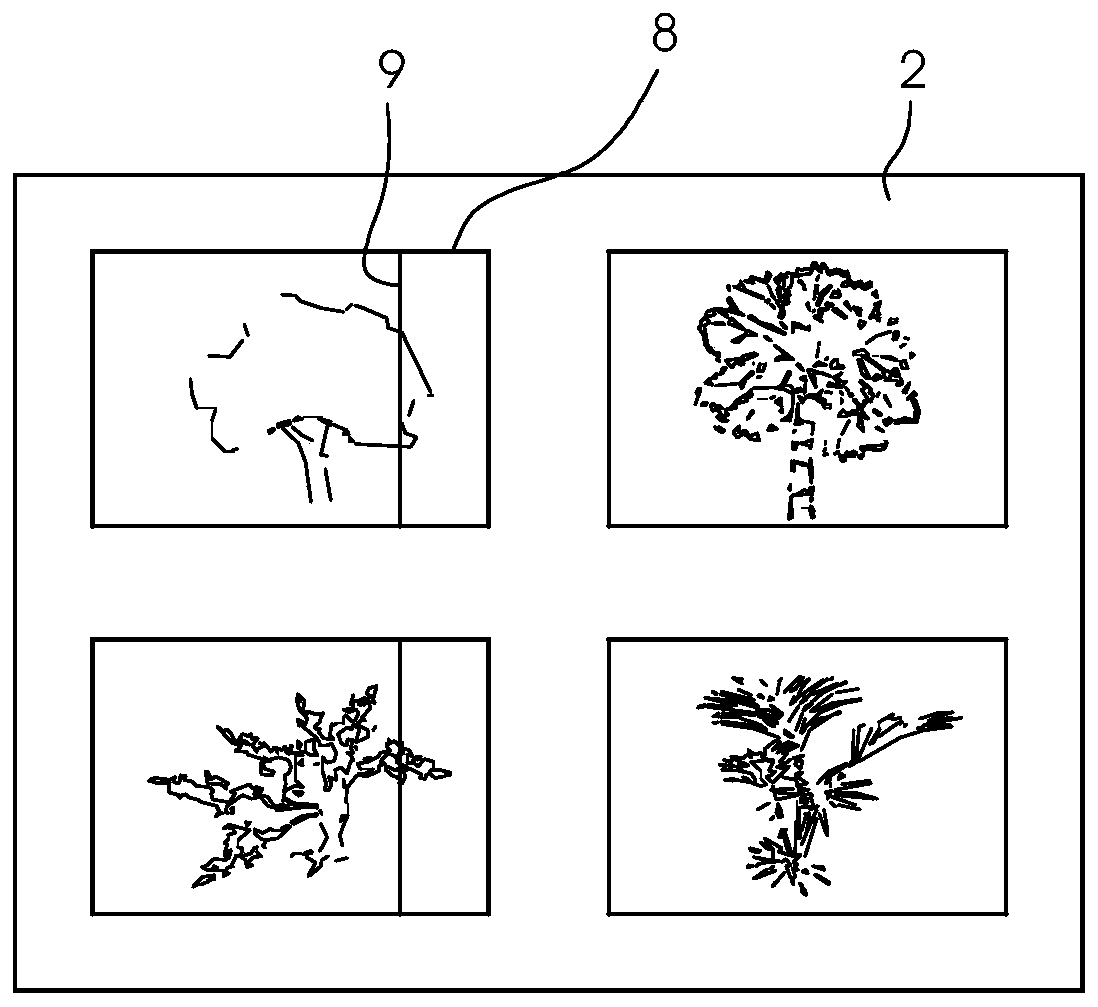

[0028] The field of application of this preferred embodiment variant is inkjet printing machines 7 . exist figure 1 An example of the basic structure of such a machine 7 is shown in , which consists of a feeder 1 up to a receiver 3 for feeding printed substrates 2 into a printing unit 4 in which the printed substrates are placed Printing is performed by the print head 5 . This is a sheet inkjet printing press 7 controlled by a control computer 6 . As already described, individual ones of the printing nozzles 5 in the printing unit 4 may fail during operation of the printing press 7 . The result is then "white lines" 9 or, in the case of multicolor printing, distorted color values. An example of such a "white line" 9 in a printed image 8 is at figure 2 shown in .

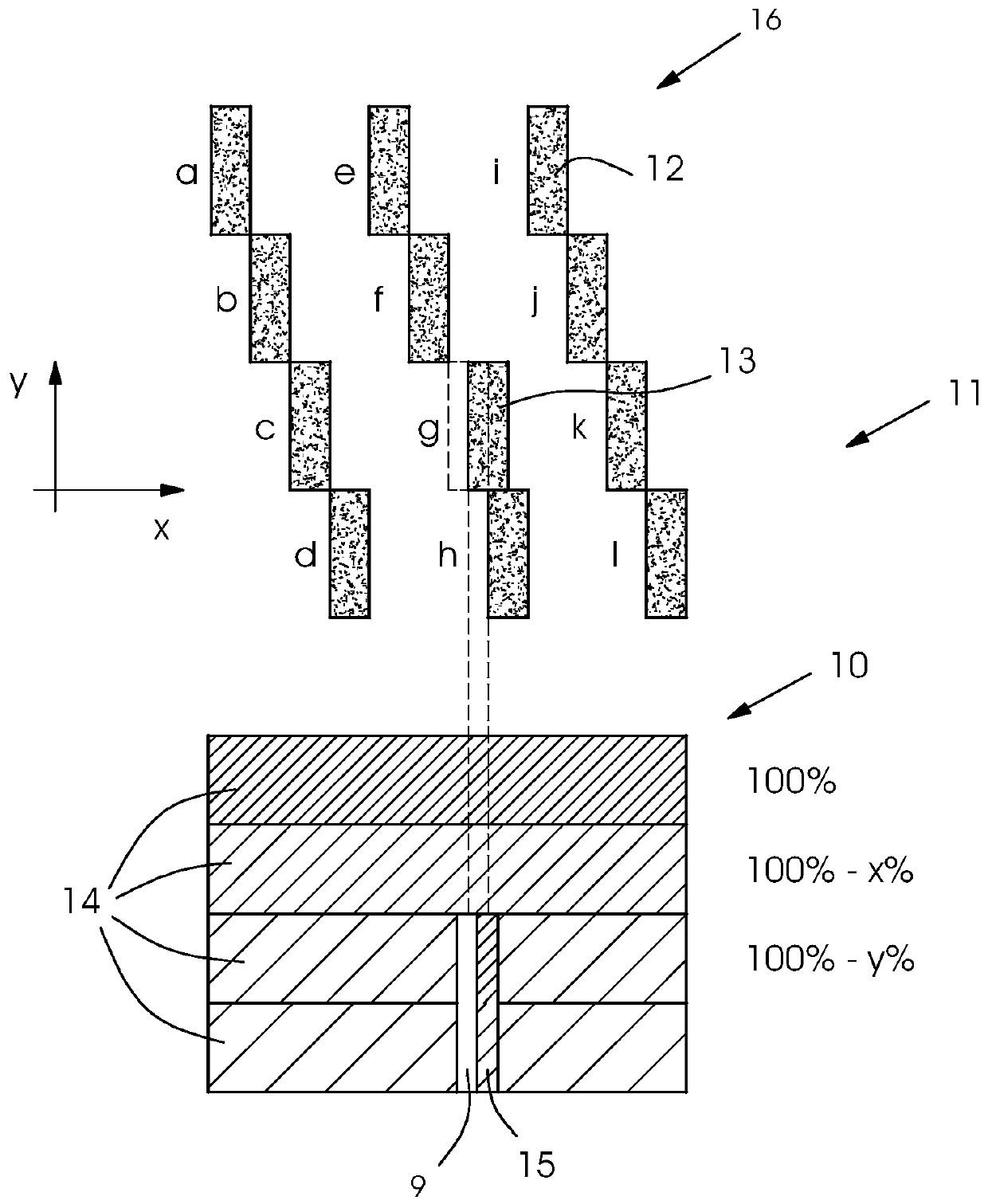

[0029] Figure 5 The sequence of the method according to the invention is shown in a preferred embodiment variant. Firstly, a combined printed nozzle test pattern 11 is printed, with an area covering element ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com