An organic photodetector based on optical microcavity effect and its preparation method

A photodetector, optical microcavity technology, applied in photovoltaic power generation, electric solid state device, semiconductor/solid state device manufacturing, etc. Good detection ability, unique structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

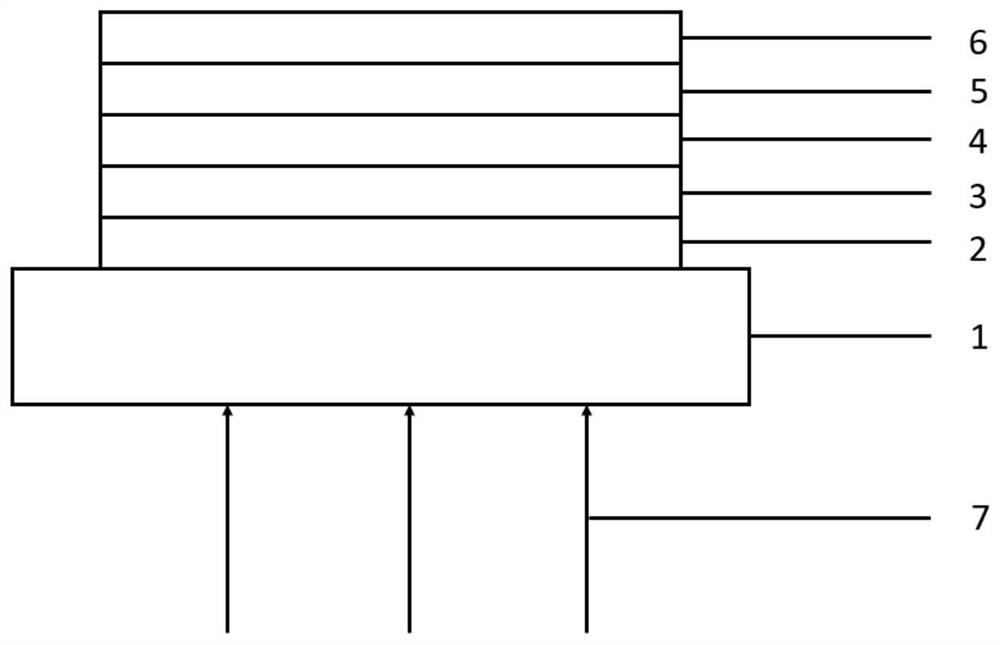

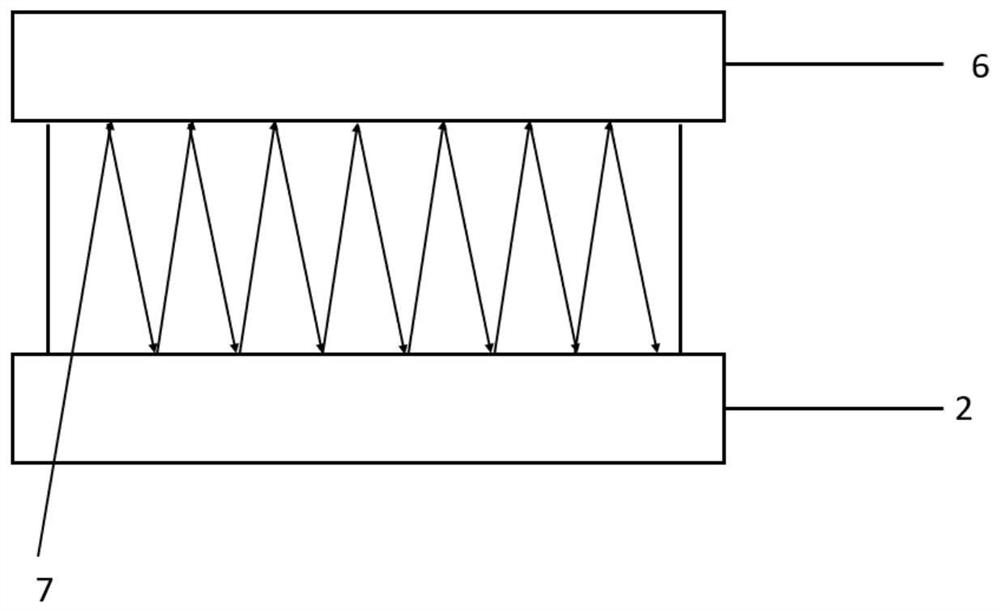

[0035] Cleaning the glass substrate 1: put the glass substrate 1 into detergent, acetone, deionized water, and isopropanol in sequence, ultrasonically clean for 15 minutes each time, and then blow dry with an inert gas. Then transfer the glass substrate 1 to the vacuum evaporation equipment, and the vacuum degree is less than 3.0×10 -3 A layer of Au electrode was evaporated in a Pa environment. Then, the transparent conductive electrode layer 2 was put into an ozone machine for UV treatment for 10 min. The mixture of PEIE and benzothiazole cyanine dye was spin-coated on the transparent conductive electrode layer 2 after ozone treatment, and the rotational speed was controlled to be 4000 rpm and the time was 20 s. . The glass substrate 1 and the organic donor-acceptor solution that have been spin-coated with the double-narrowband modulation layer 3 were preheated at 100 °C, and the acceptor solution was spin-coated on the surface of the double-narrowband modulation layer 3 wi...

Embodiment 2

[0038] Cleaning the glass substrate 1: put the glass substrate 1 into detergent, acetone, deionized water, and isopropanol in sequence, ultrasonically clean for 15 minutes each time, and then blow dry with an inert gas. Then transfer the glass substrate 1 to the vacuum evaporation equipment, and the vacuum degree is less than 3.0×10 -3 A layer of Au electrode was evaporated in a Pa environment. Then, the transparent conductive electrode layer 2 was put into an ozone machine for UV treatment for 10 min. The mixture of PEIE and benzothiazole cyanine dye was spin-coated on the transparent conductive electrode layer 2 after ozone treatment, and the rotational speed was controlled to be 4000 rpm and the time was 20 s. . The glass substrate 1 and the organic donor-acceptor solution that have been spin-coated with the double-narrowband modulation layer 3 were preheated at 100 °C, and the acceptor solution was spin-coated on the surface of the double-narrowband modulation layer 3 wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com