Organic photoelectric detector based on optical microcavity effect and preparation method thereof

A photodetector and optical microcavity technology, which is applied in photovoltaic power generation, electrical solid-state devices, semiconductor/solid-state device manufacturing, etc., can solve the problems of low detection rate, difficult separation of long-wavelength excitons, and low external quantum efficiency, achieving The effect of unique structure and good detection ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

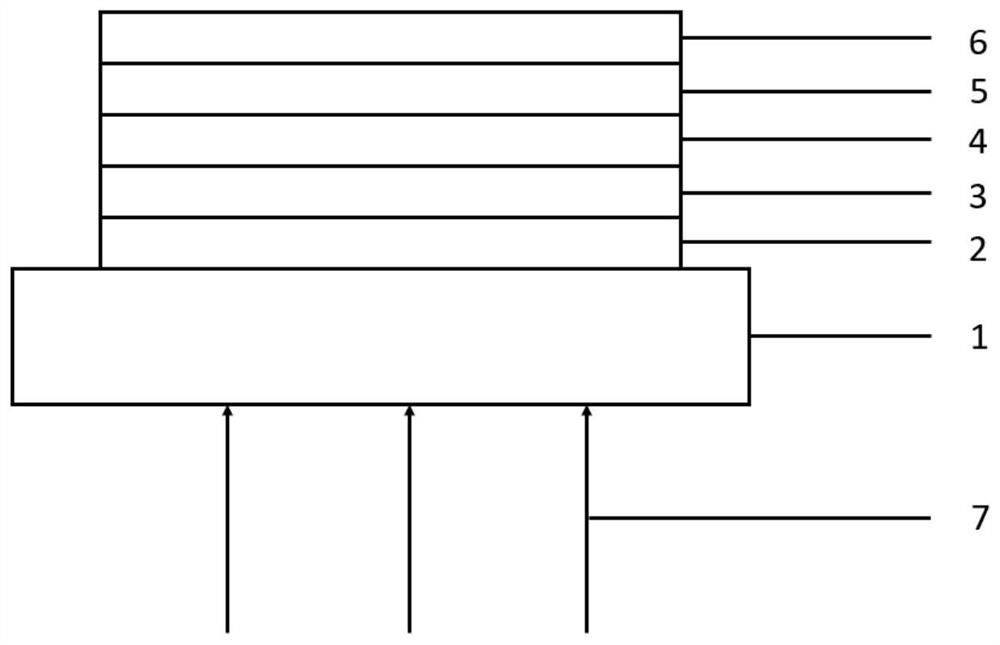

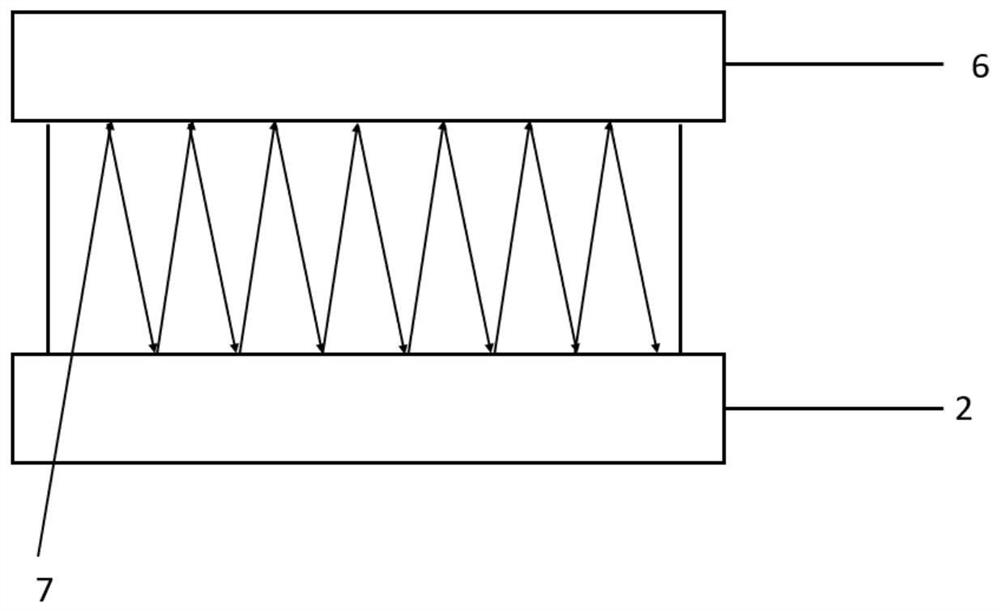

[0035] Clean the glass substrate 1: put the glass substrate 1 into detergent, acetone, deionized water, and isopropanol in sequence, ultrasonically clean it for 15 minutes each time, and then dry it with an inert gas. Then the glass substrate 1 is transferred to the vacuum evaporation equipment, and the vacuum degree is less than 3.0×10 -3 A layer of Au electrode was vapor-deposited in Pa environment. Then put the transparent conductive electrode layer 2 into an ozone machine for UV treatment for 10 minutes. The mixture of PEIE and benzothiazocyanine dye was spin-coated on the transparent conductive electrode layer 2 after ozone treatment, the rotation speed was controlled at 4000rpm, the time was 20s, and then annealing was performed, the annealing temperature was controlled at 150°C, and the time was 15min. . Preheat the glass substrate 1 and the organic donor-receptor solution on which the double-narrow-band modulation layer 3 has been spin-coated at 100° C., spin-coat th...

Embodiment 2

[0038] Clean the glass substrate 1: put the glass substrate 1 into detergent, acetone, deionized water, and isopropanol in sequence, ultrasonically clean it for 15 minutes each time, and then dry it with an inert gas. Then the glass substrate 1 is transferred to the vacuum evaporation equipment, and the vacuum degree is less than 3.0×10 -3 A layer of Au electrode was vapor-deposited in Pa environment. Then put the transparent conductive electrode layer 2 into an ozone machine for UV treatment for 10 minutes. The mixture of PEIE and benzothiazocyanine dye was spin-coated on the transparent conductive electrode layer 2 after ozone treatment, the rotation speed was controlled at 4000rpm, the time was 20s, and then annealing was performed, the annealing temperature was controlled at 150°C, and the time was 15min. . Preheat the glass substrate 1 and the organic donor-receptor solution on which the double-narrow-band modulation layer 3 has been spin-coated at 100° C., spin-coat th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com