A method for eliminating short process to produce 1.175mm high-strength steel coiled oval coil

A high-strength steel, short-process technology, applied in the direction of manufacturing tools, tension/pressure control, metal rolling, etc., can solve problems affecting production efficiency, product degradation or scrapping, increasing manpower and material resources, etc., to achieve the elimination of oval The effect of shape roll defects, promotion of tissue phase transformation, and simple and easy method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

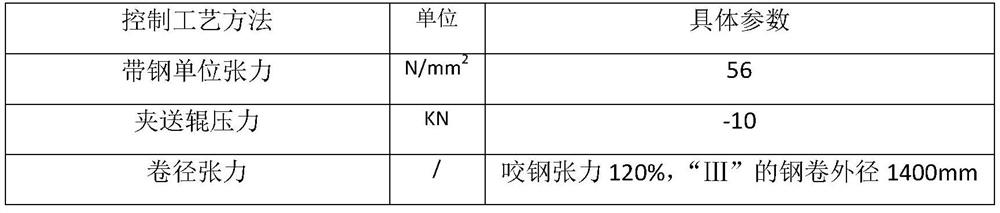

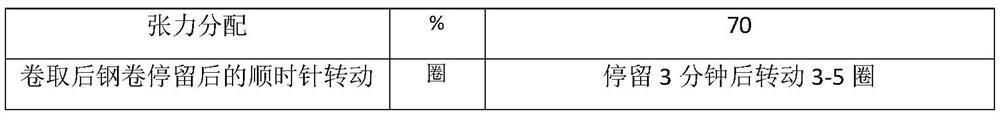

[0031] WJX750-NH was produced on December 4, 2018, size: 1.175mm*1115mm.

[0032] control process method unit Specific parameters Strip unit tension N / mm 2

[0033] Effect: 20 coils of steel were produced, totaling 308.35 tons, and the non-elliptical rate of coils was 100%.

example 2

[0034] Example 2: WJX750-NH was produced on December 10, 2018, June 7, 2019, and June 12, 2019, size: 1.175mm*1175mm.

[0035] control process method unit Specific parameters Strip unit tension N / mm 2

[0036] Effect: 30 coils of steel were produced, totaling 531.68 tons, and the non-oval rate of coils was 100%.

Embodiment 3

[0038] On March 30, 2019, and April 10, 2019, WJX750-NH was produced. Size specification: 1.175mm*1195mm.

[0039]

[0040]

[0041] Effect: 24 coils of steel were produced, totaling 378.94 tons, and the non-oval rate of coils was 100%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com