Patents

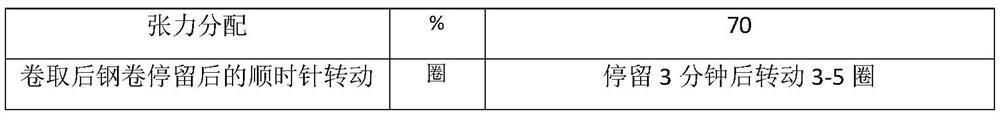

Literature

49results about How to "Make sure it's tight" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

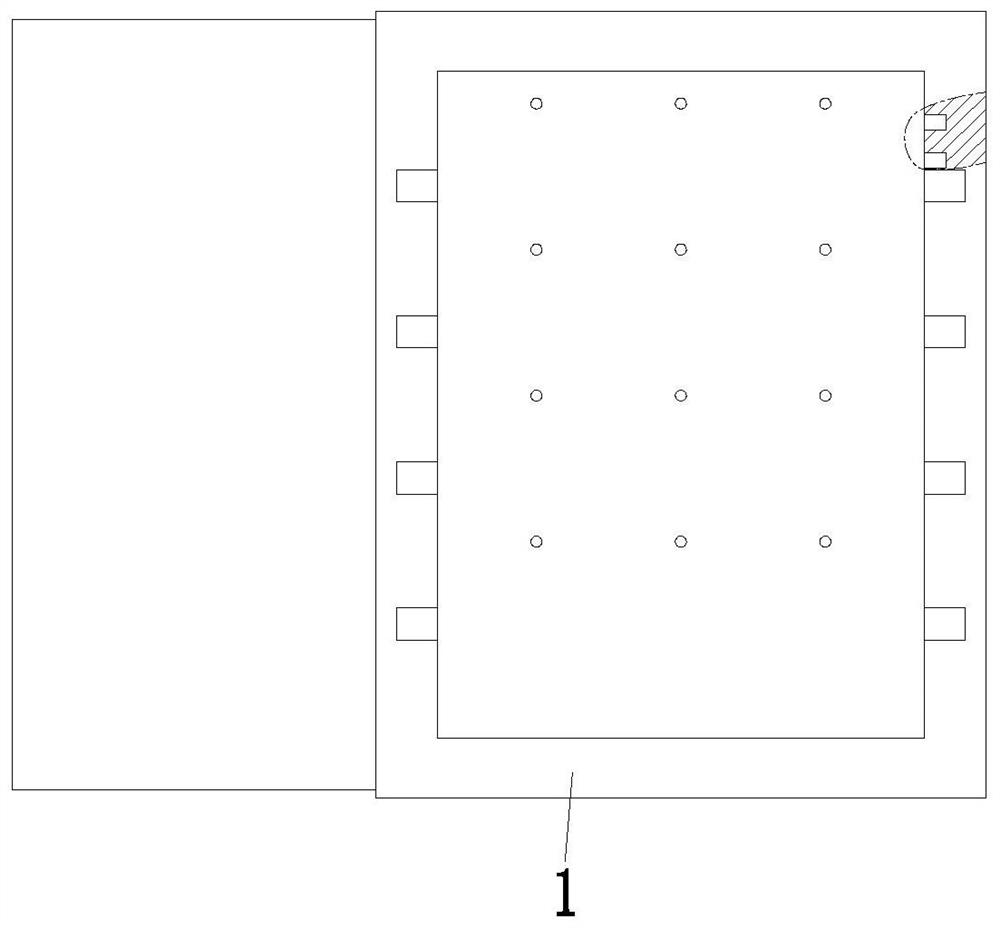

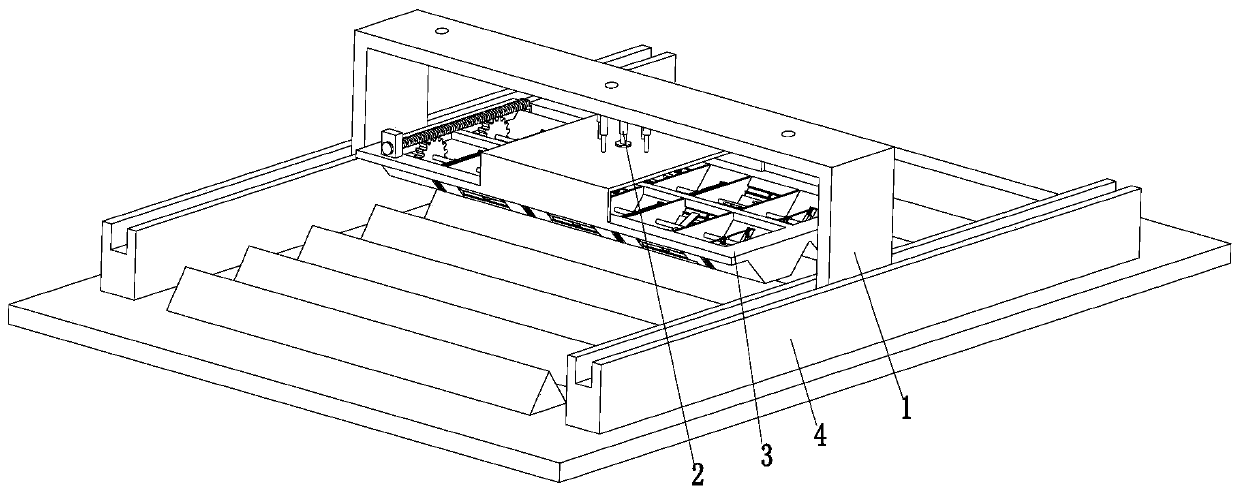

Corrugated paper rolling equipment

InactiveCN108861878ANot easy to roll tightDamage will notWebs handlingPulp and paper industryUltimate tensile strength

Owner:泉州金百利包装用品有限公司

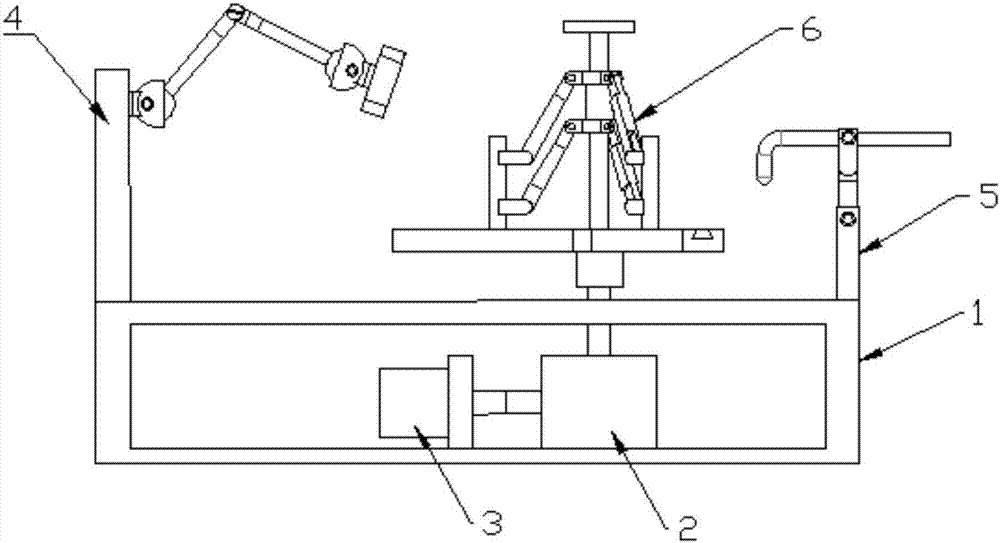

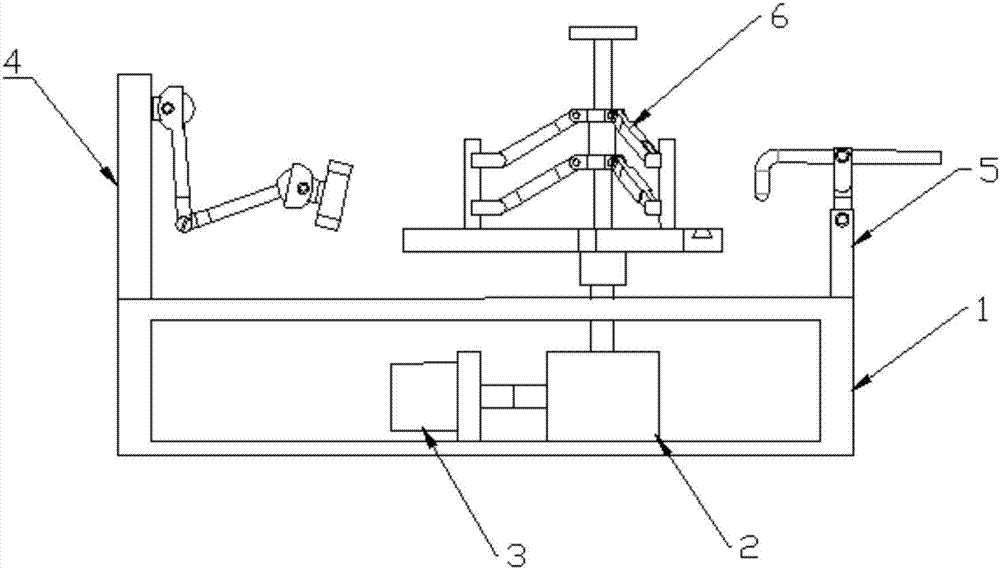

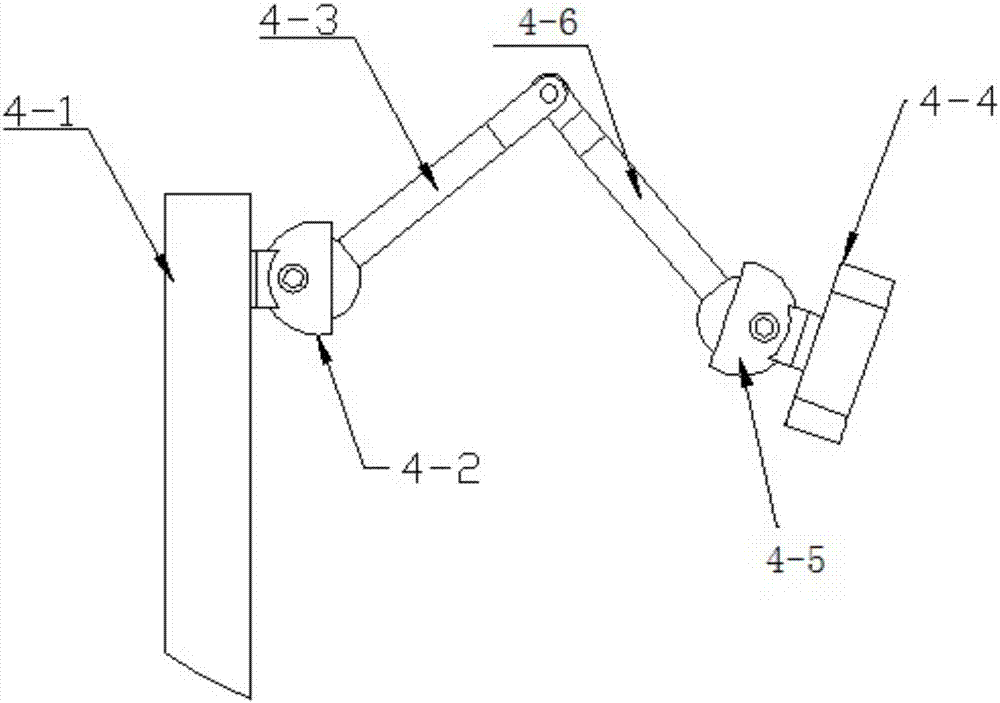

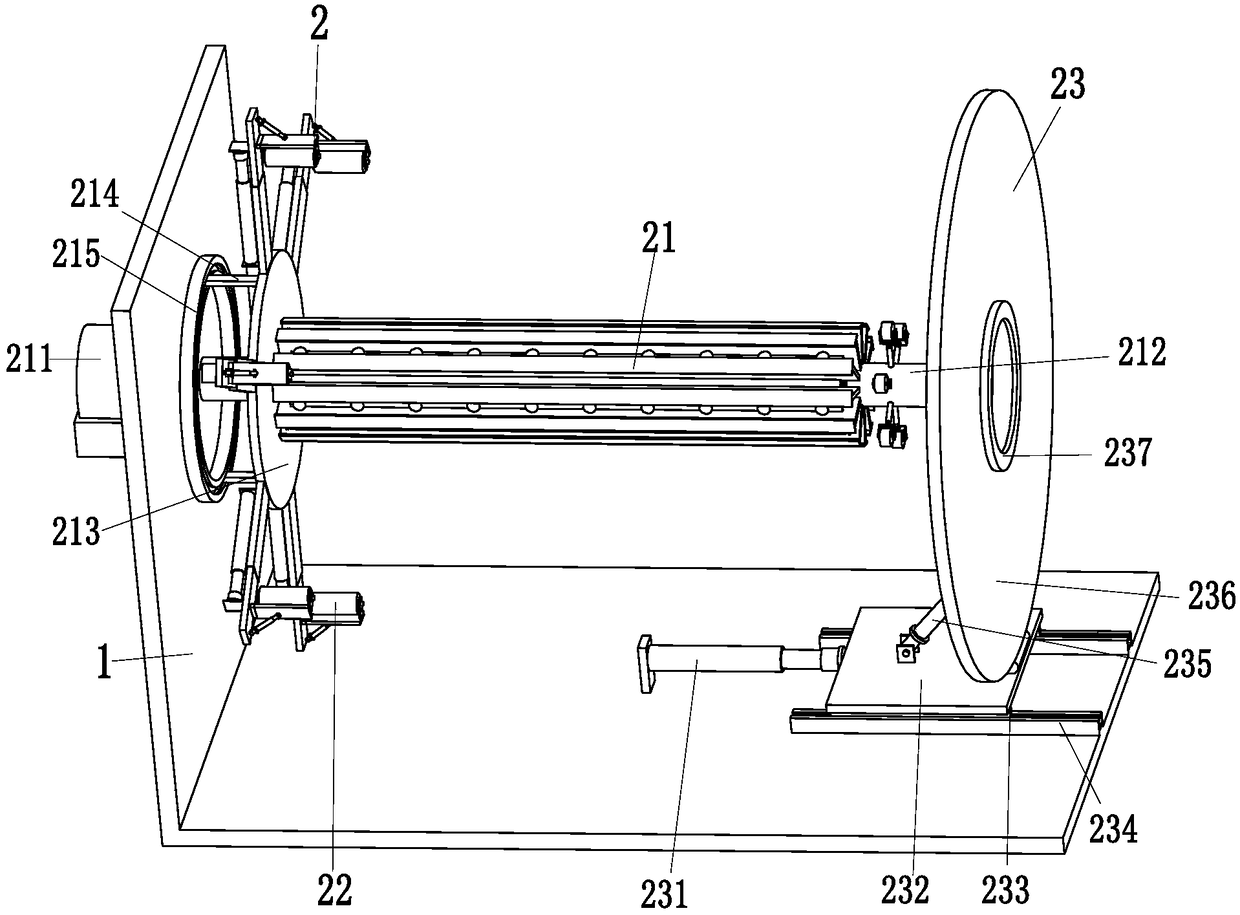

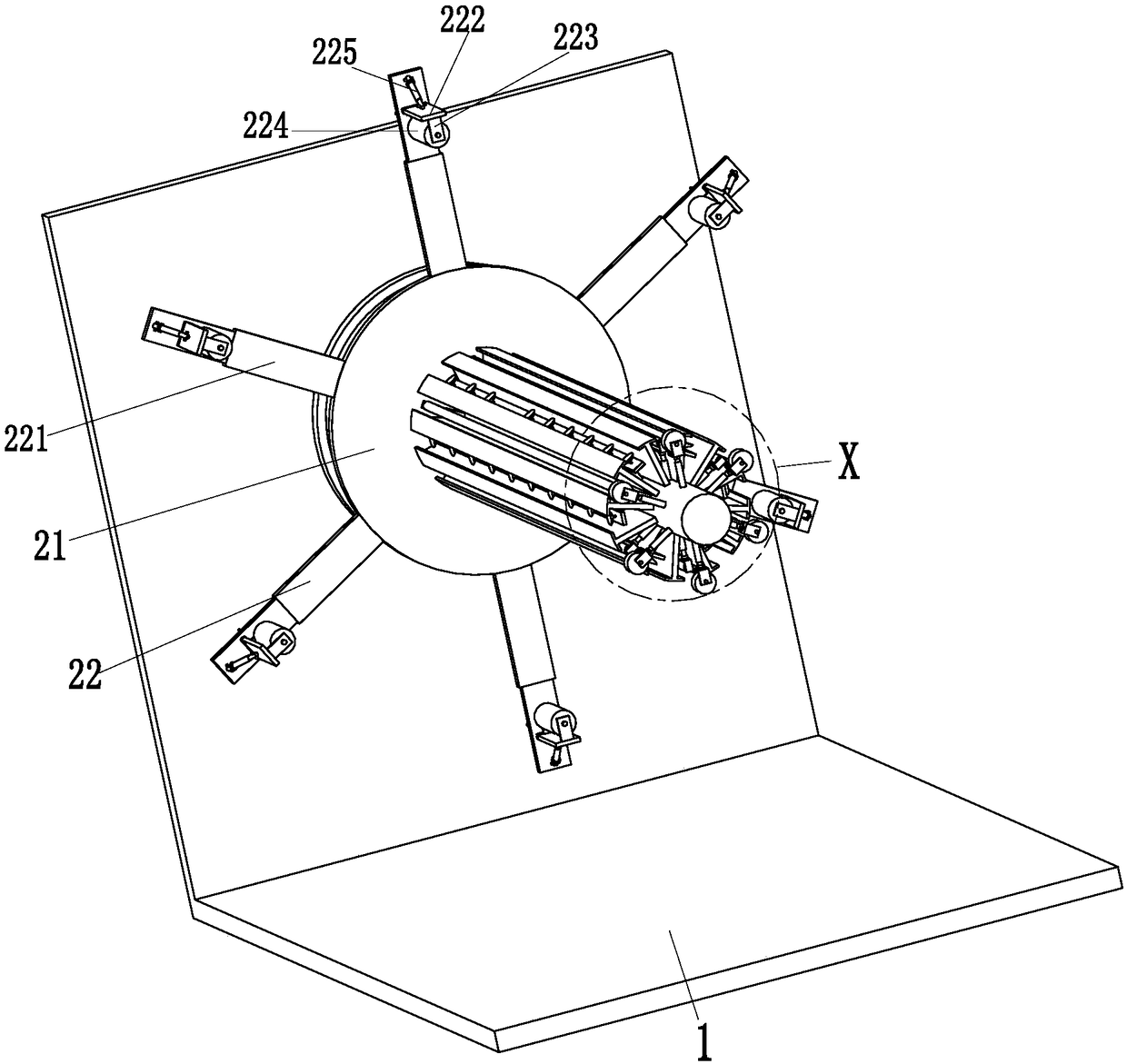

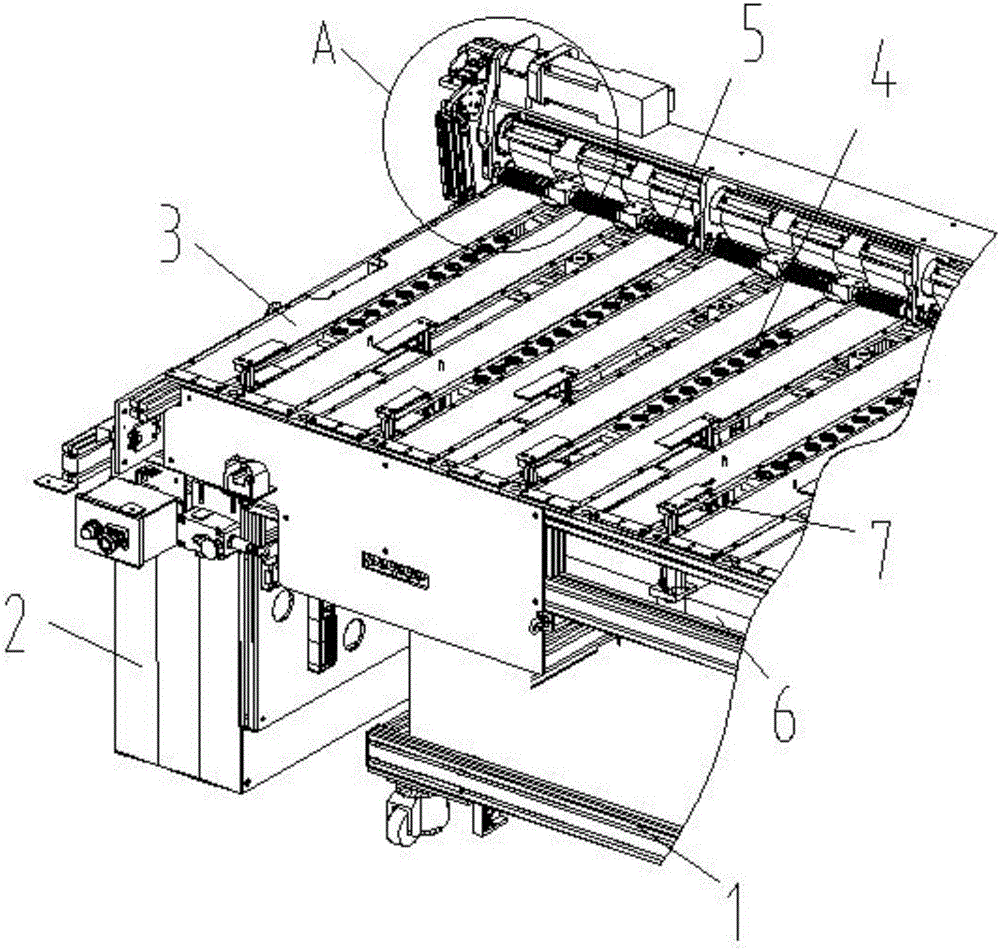

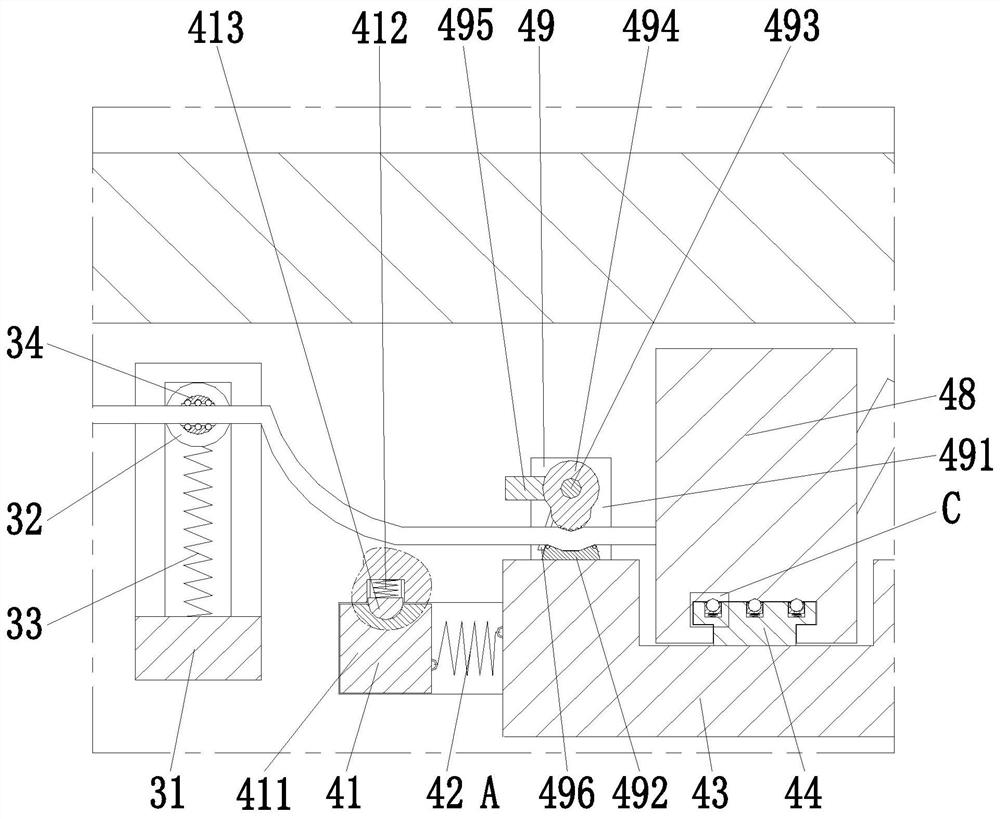

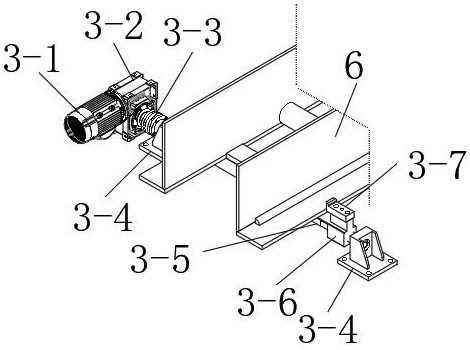

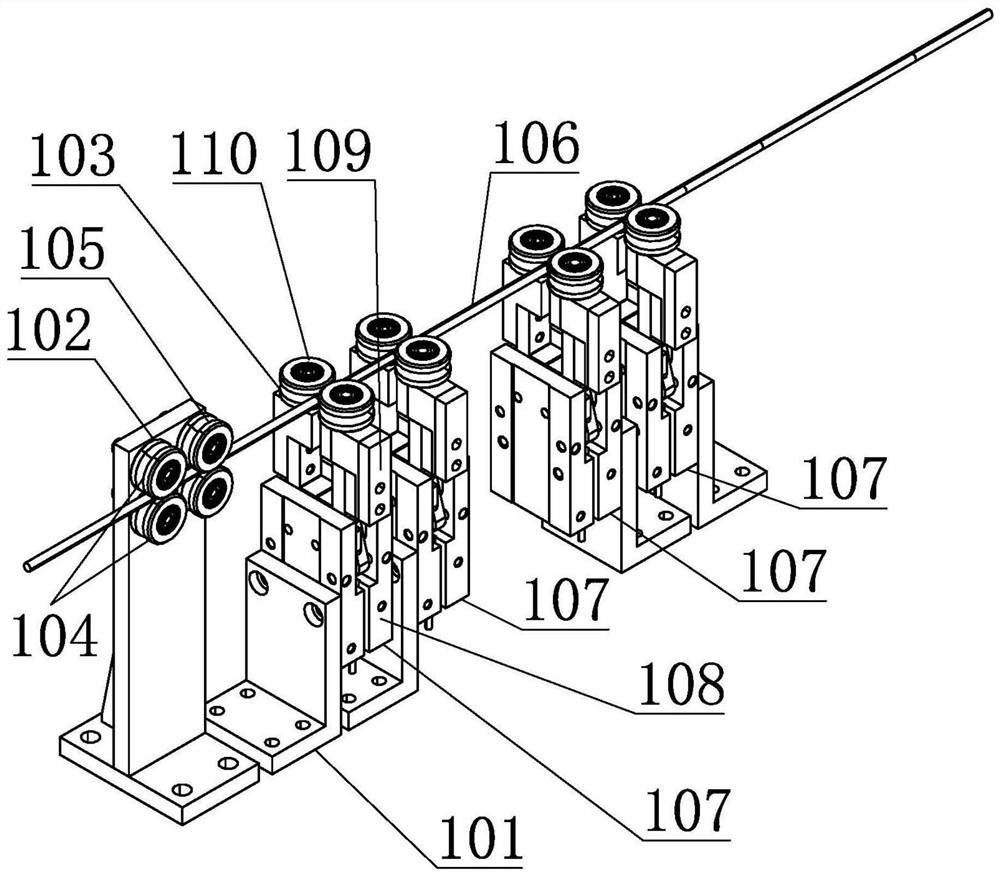

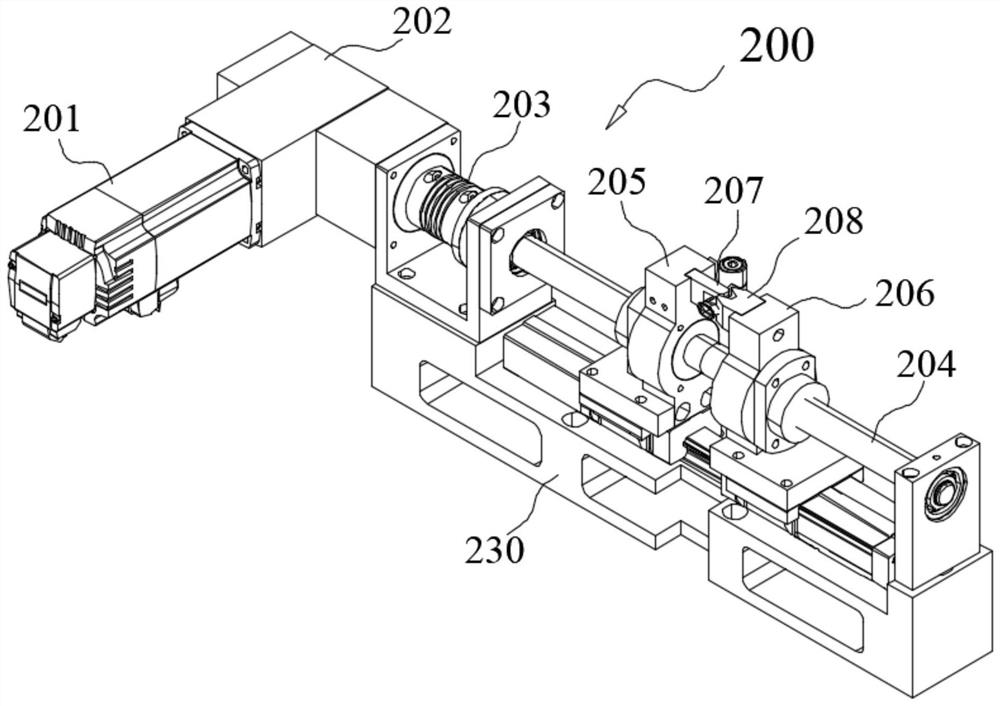

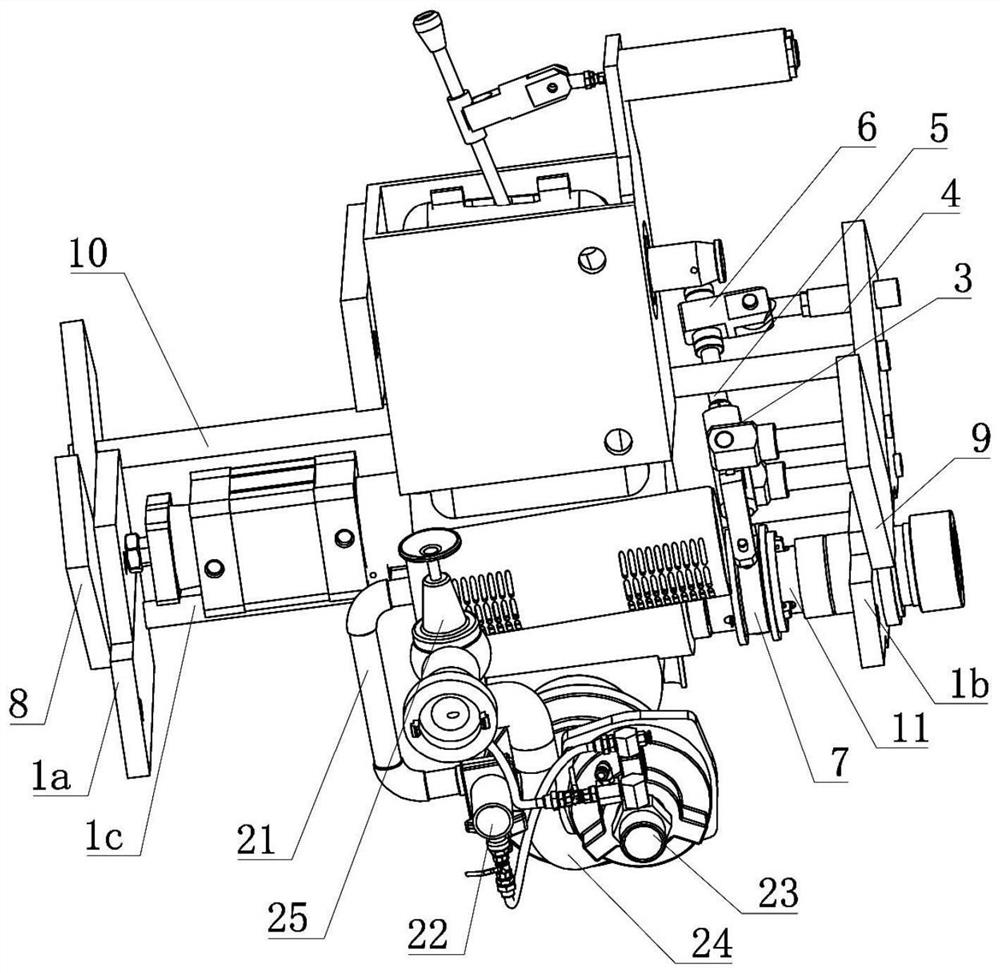

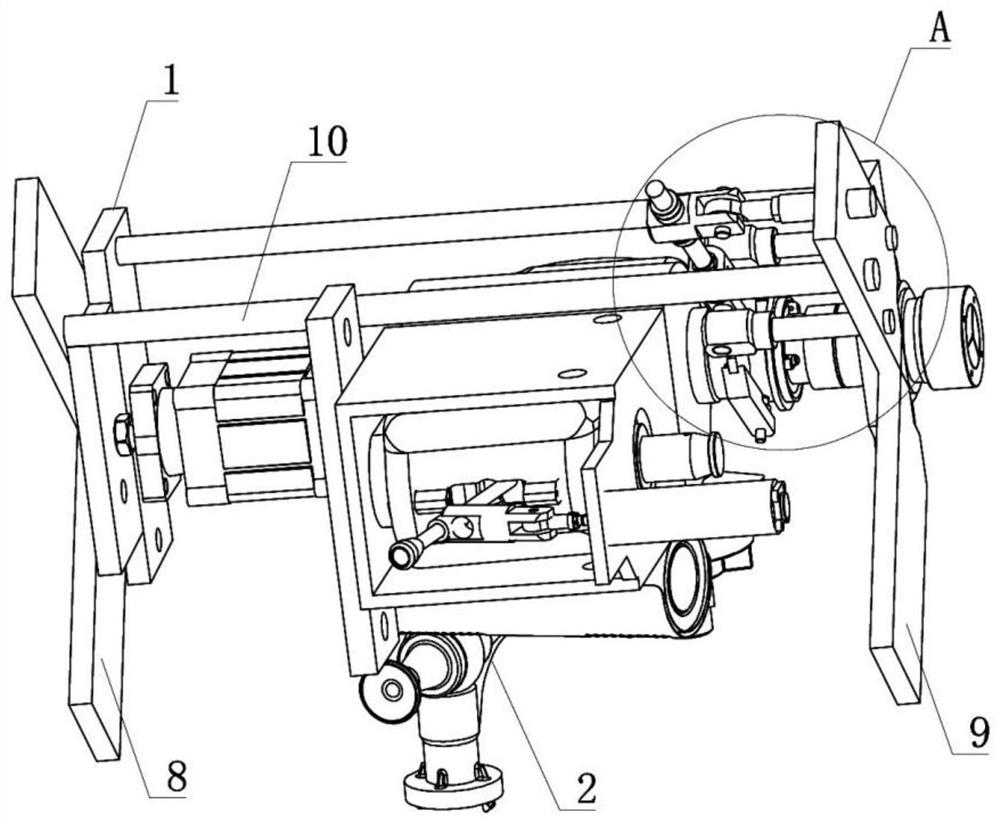

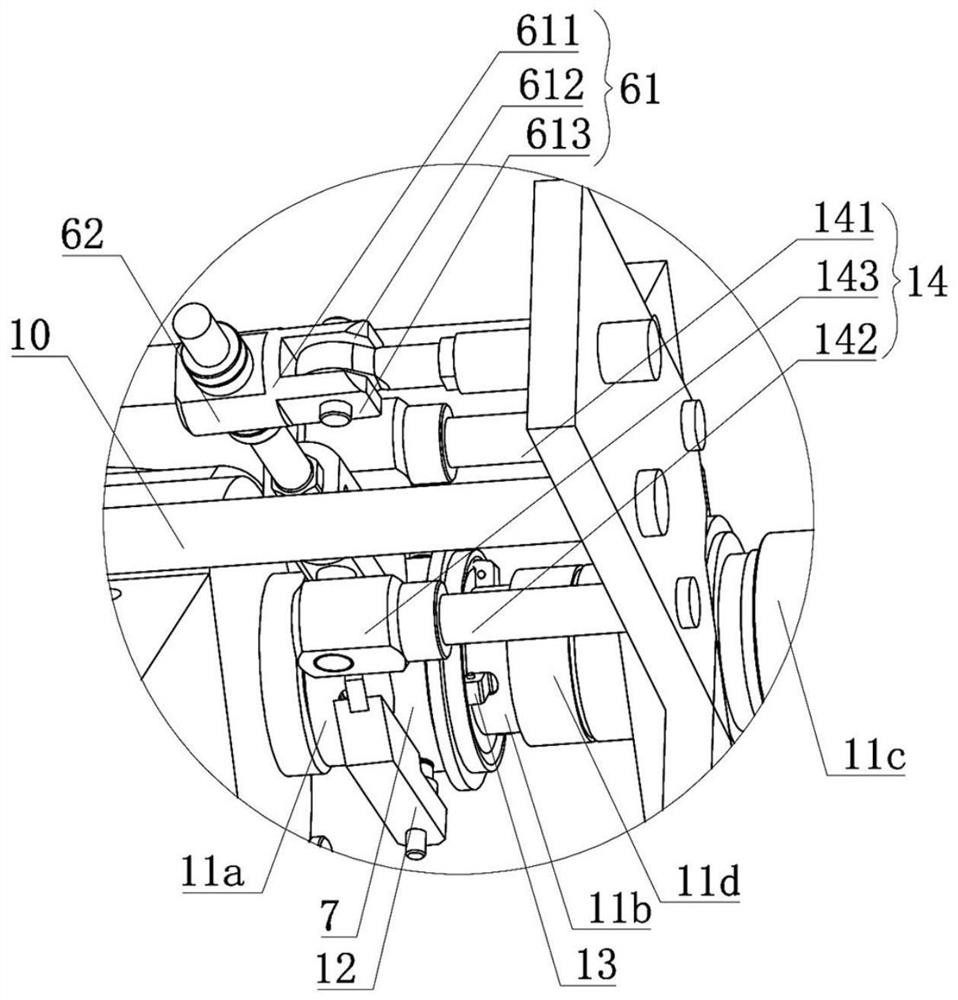

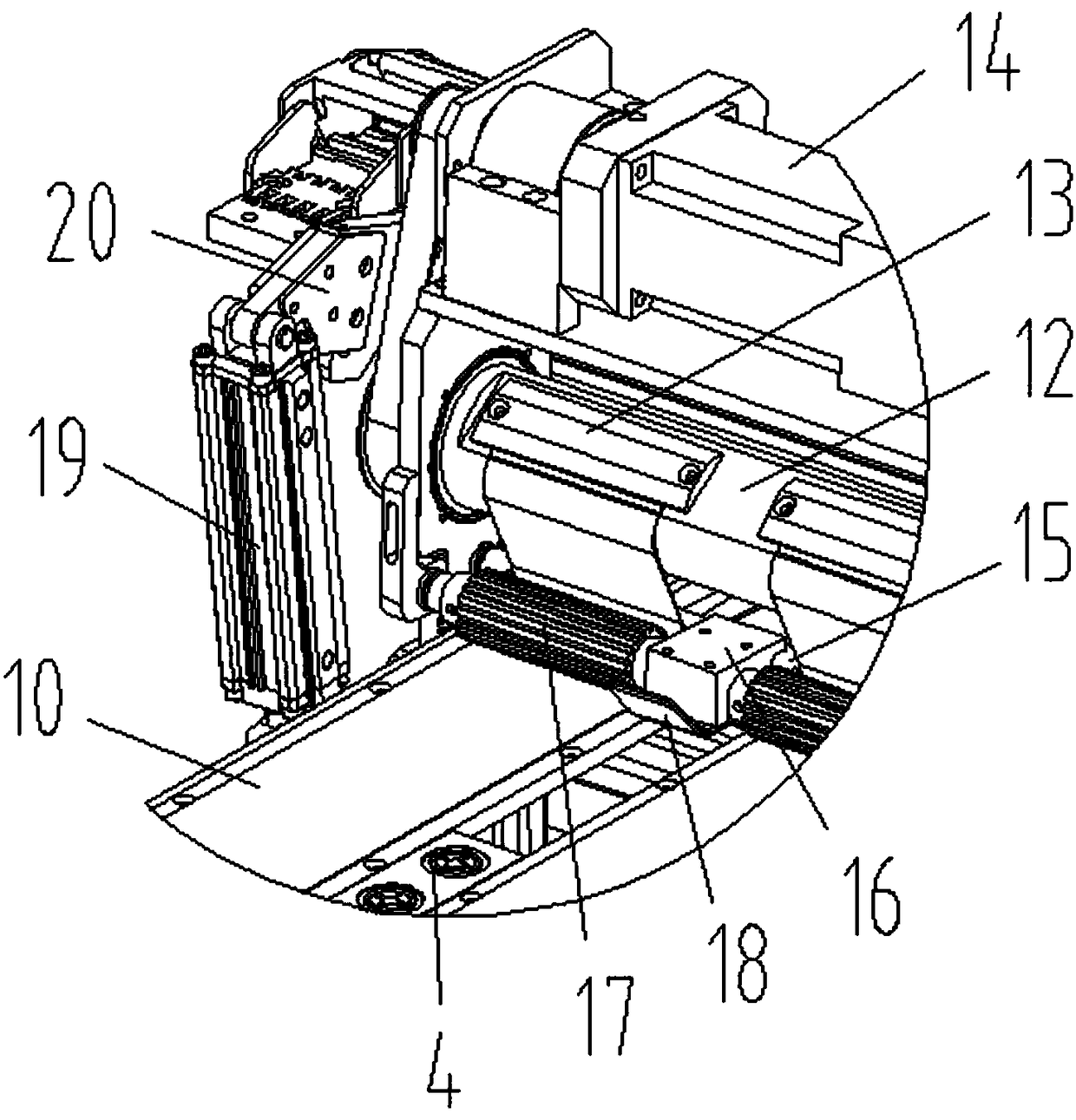

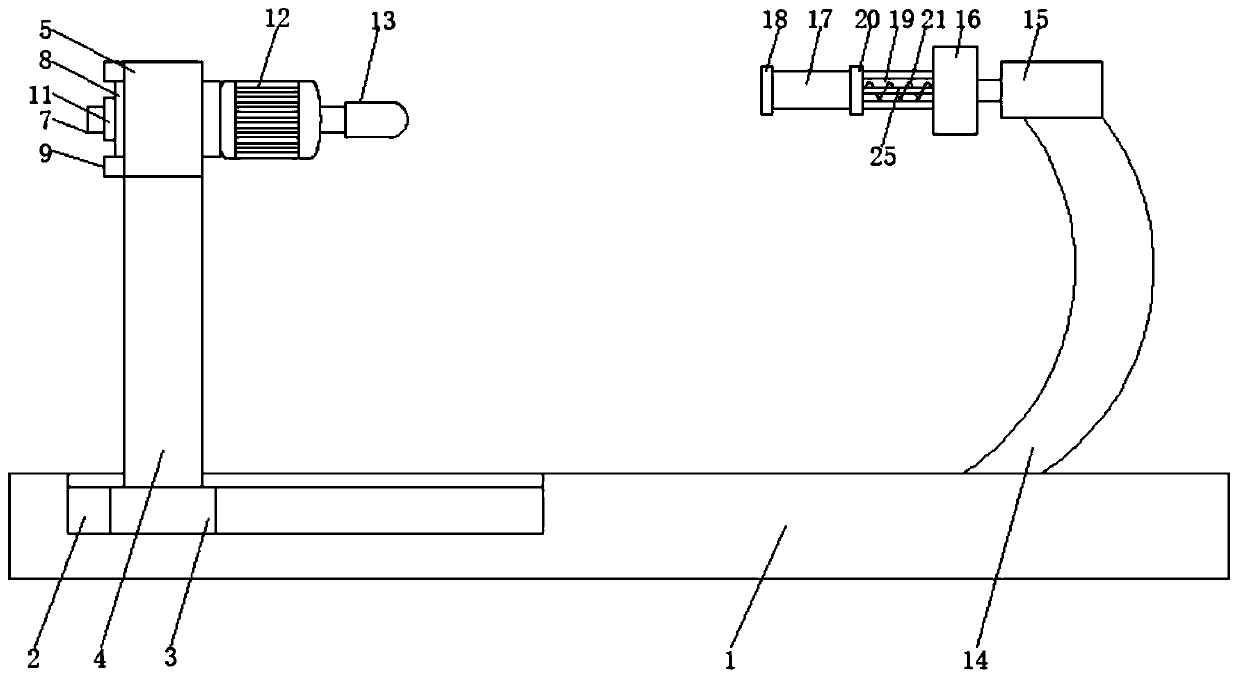

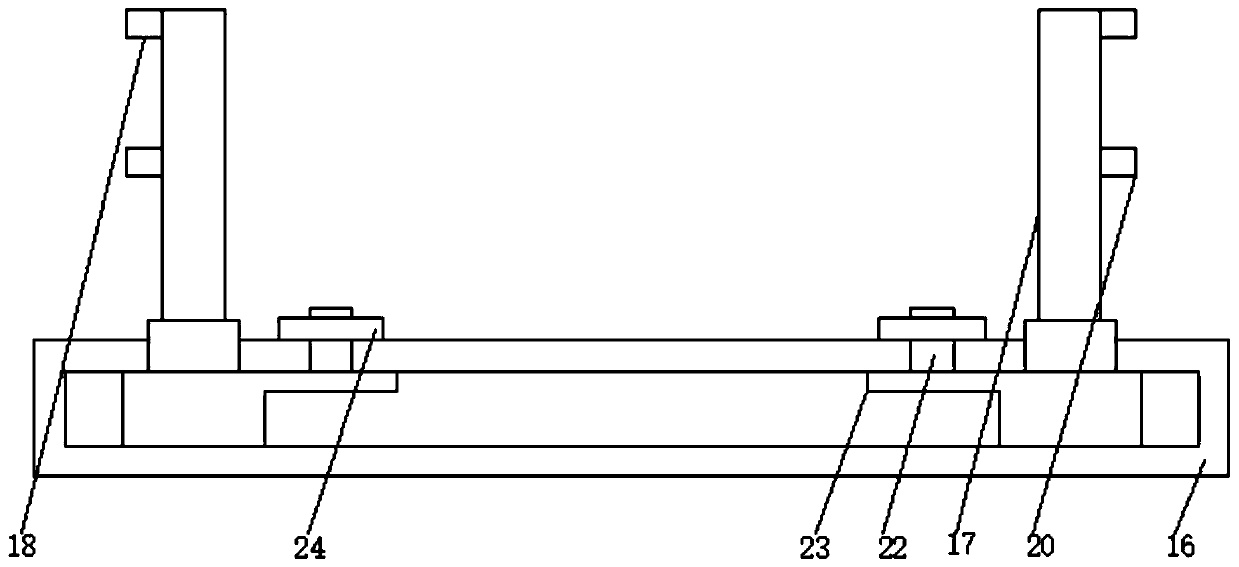

Rear axle gear matching mark photographing system

InactiveCN107314760AAchieve fixationGuaranteed accuracyPicture taking arrangementsGear wheelEngineering

The invention discloses a rear axle gear matching mark photographing system. The rear axle gear matching mark photographing system comprises a base, a driving mechanism, a photographing mechanism and a tightening mechanism, wherein the tightening mechanism comprises a support, a plurality of positioning columns, lead screws, connecting nuts and first connecting rods, wherein gears are placed on the support; the positioning columns are positioned on the support and can slide relative to the support; the lead screws are parallel to the positioning columns; each connecting nut sleeves the corresponding lead screw; each connecting nut is connected with the corresponding positioning column by the corresponding first connecting rod; the positioning columns are abutted to the inner surface of a gear and are jointly matched with one another to fix the gear; the driving mechanism is mounted on the base; an output shaft of the driving mechanism is fixedly connected with the support to drive the support to rotate; and the photographing mechanism comprises an adjusting device which is mounted on the base and can adjust a photographing angle and a camera which is fixed at a head end of the adjusting device. By the rear axle gear matching mark photographing system, the photographing angles of gears in different models can be fixed.

Owner:WUHAN UNIV OF TECH

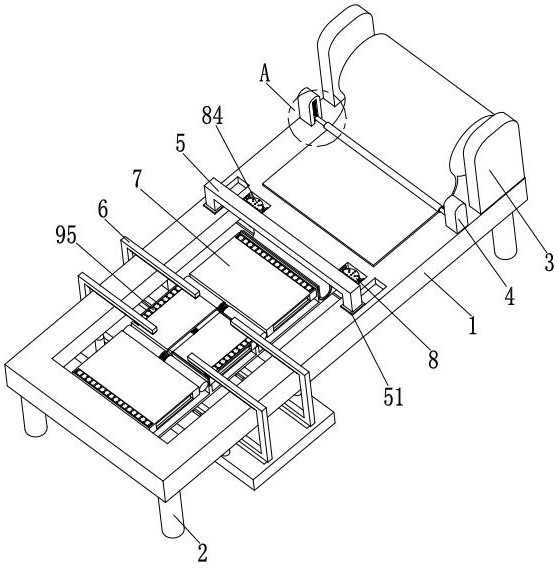

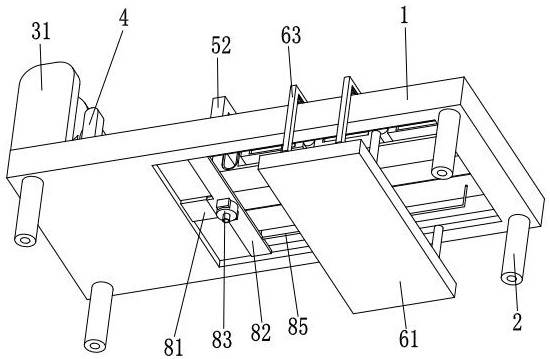

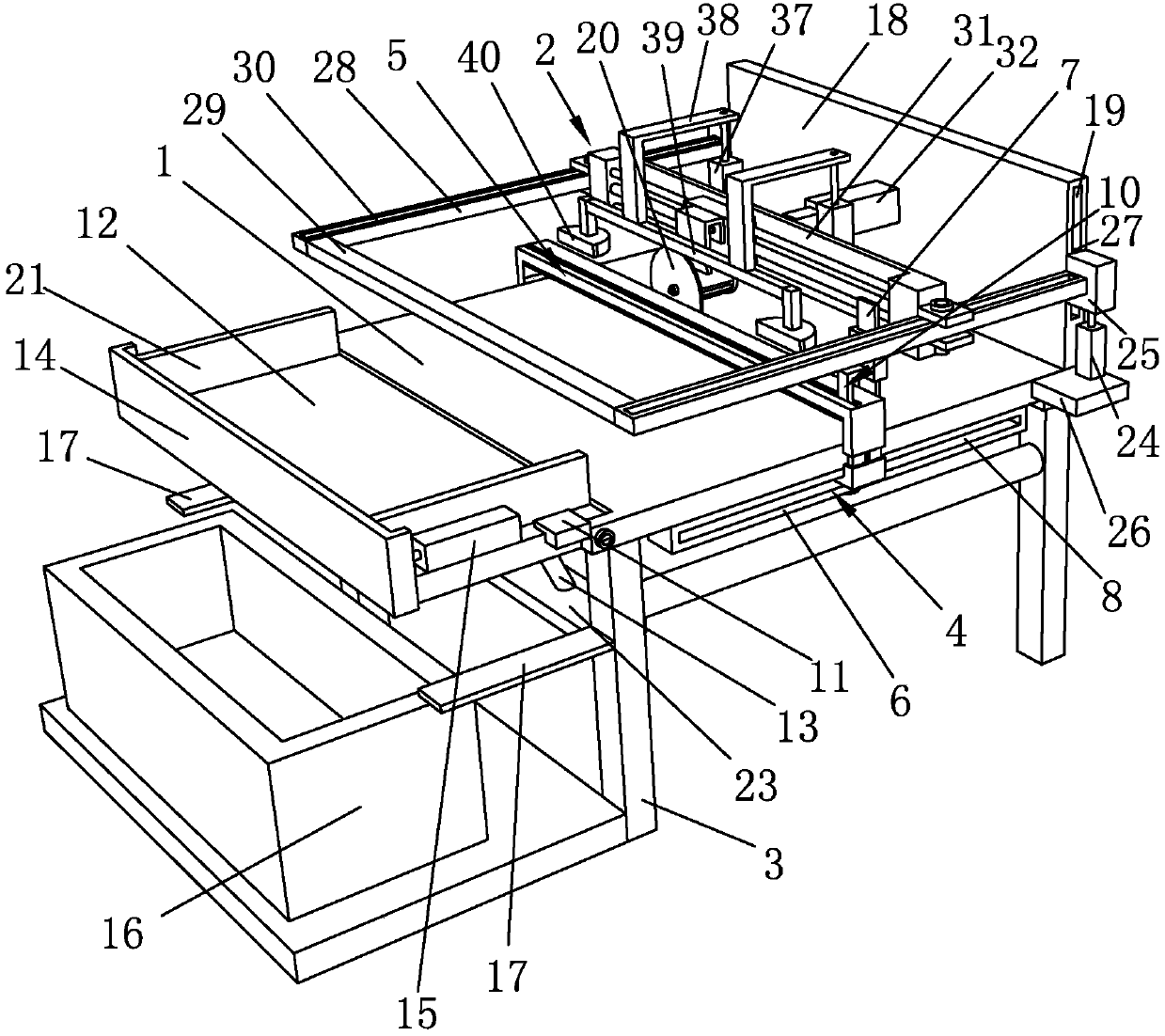

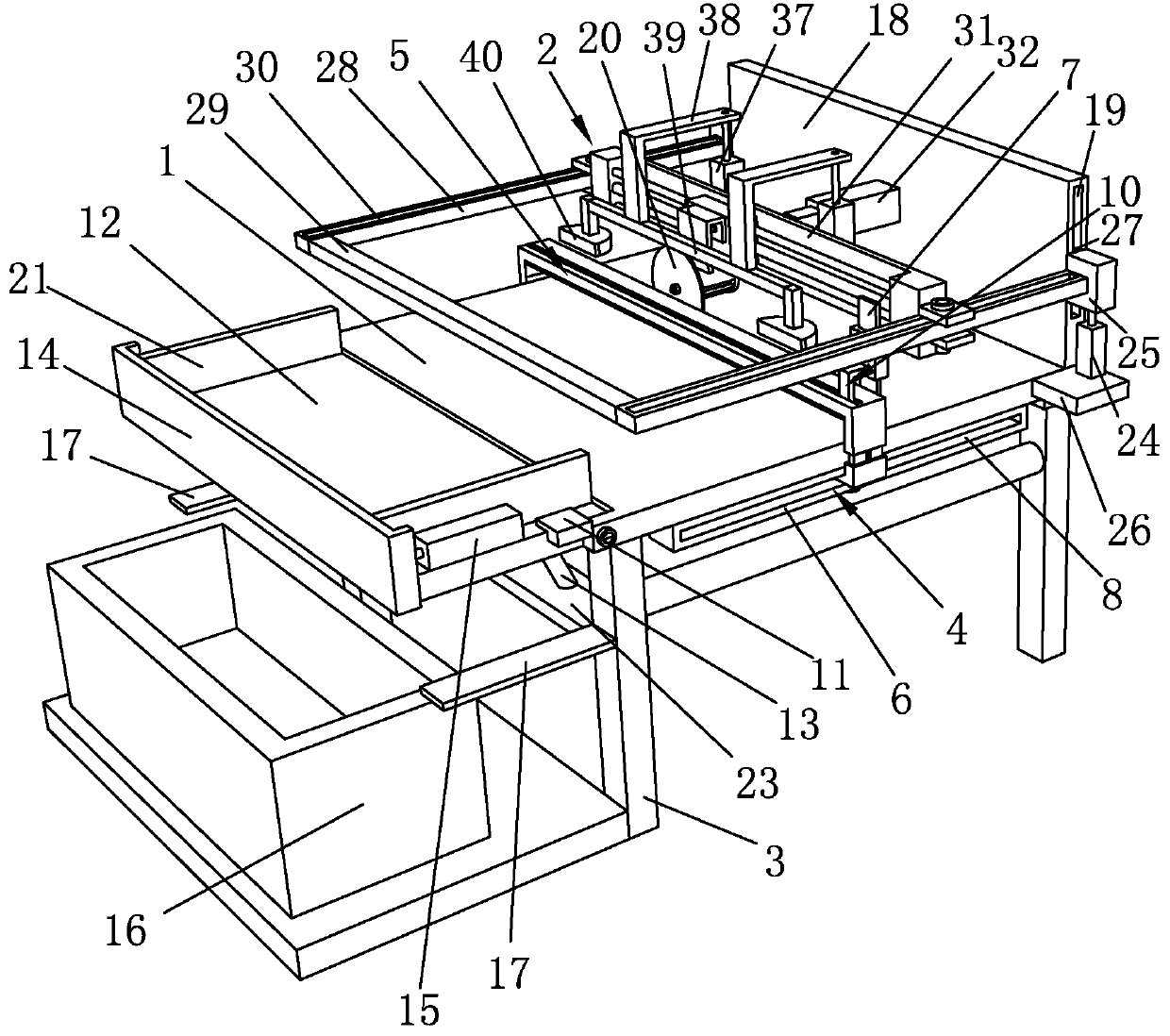

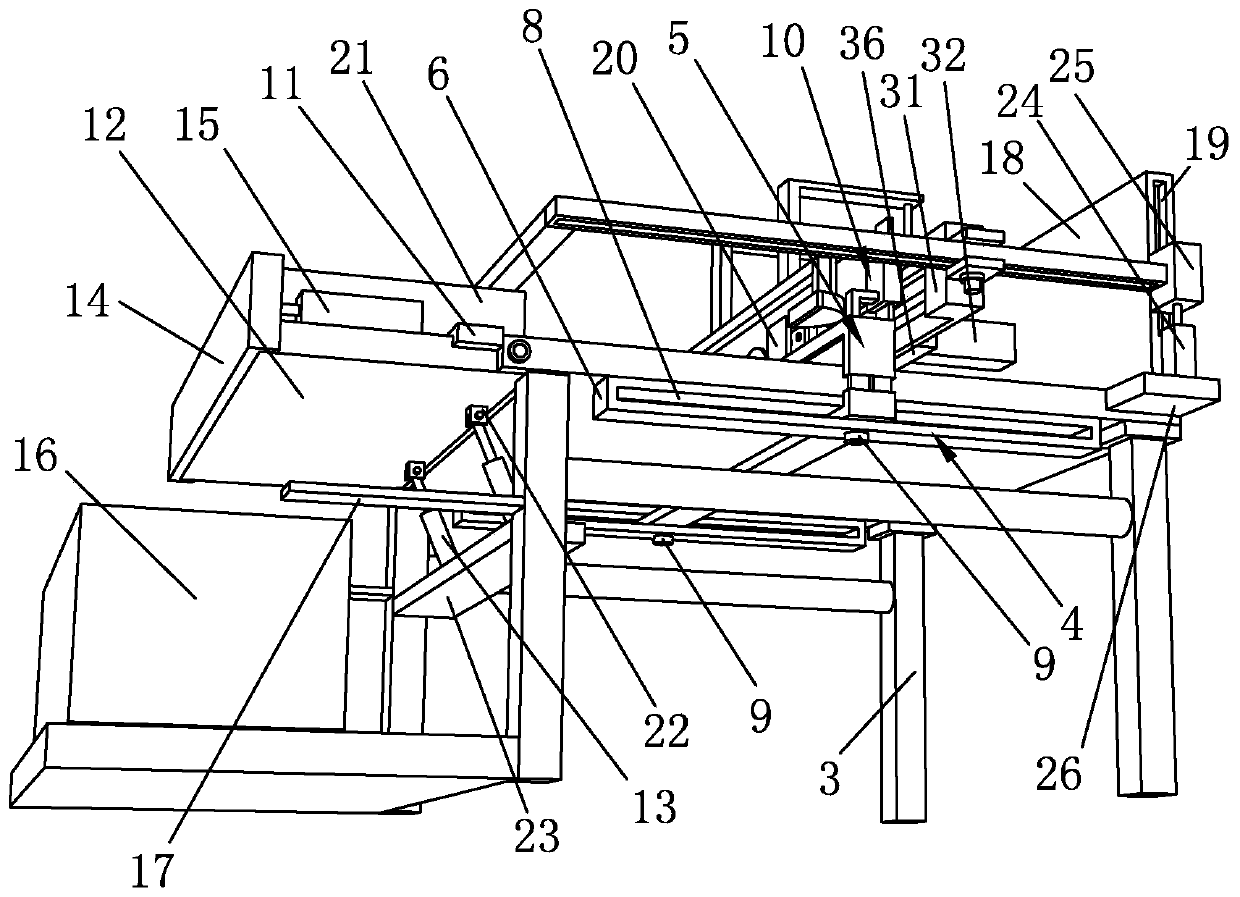

Automatic folding device for disposable bed sheet production

ActiveCN113860056ARealize automatic foldingImprove folding efficiencyFolding thin materialsPackagingEngineeringLaser cutting

The invention relates to the technical field of bed sheet production and manufacturing, in particular to an automatic folding device for disposable bed sheet production. The automatic folding device for disposable bed sheet production comprises a bottom plate, a supporting frame, an unwinding unit, a limiting unit, a laser cutting unit, a pressing unit, a folding unit and an adsorption moving unit. The automatic folding device for disposable bed sheet production provided by the invention solves the problems that in the existing bed sheet folding process, due to the fact that a bed sheet is made of a flexible material, the surface of the bed sheet is prone to wrinkling due to the lack of appropriate limiting in the folding process, and the folding effect of the bed sheet is affected; and the bed sheet is made of the flexible material, so that the surface of the bed sheet is usually clamped by a clamp to pull the bed sheet in the process of pulling the bed sheet, the surface of the bed sheet is easily damaged, and the later use effect of the bed sheet is influenced. According to the automatic folding device for disposable bed sheet production provided by the invention, the folding effect of the disposable bed sheet is improved, and the surface of the bed sheet is always kept in a flat state in the folding process of the bed sheet.

Owner:徐州旅悠旅游用品有限公司

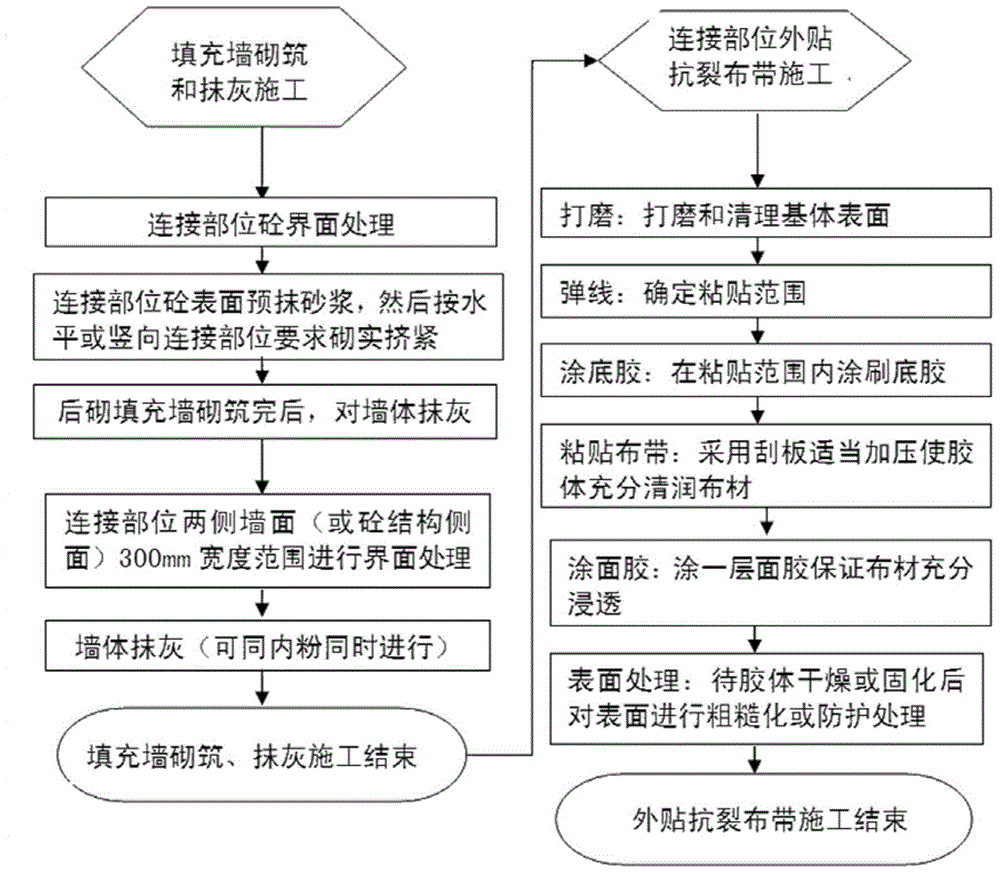

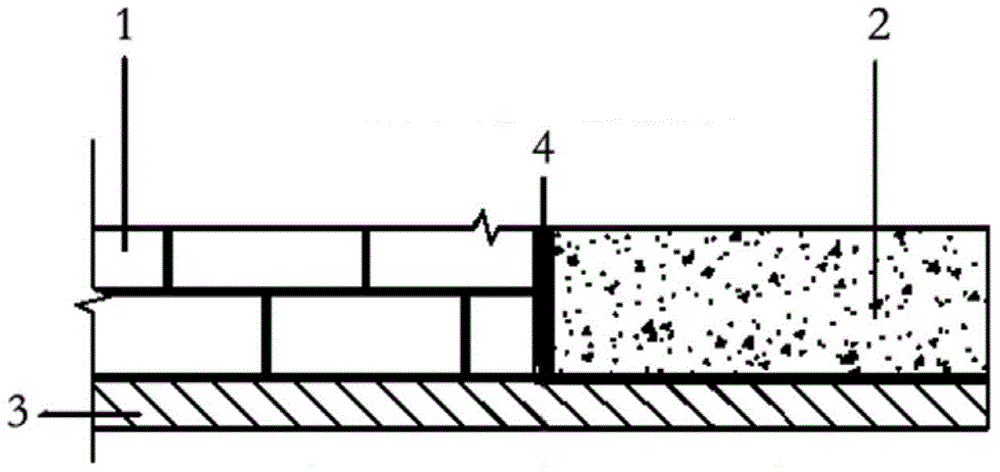

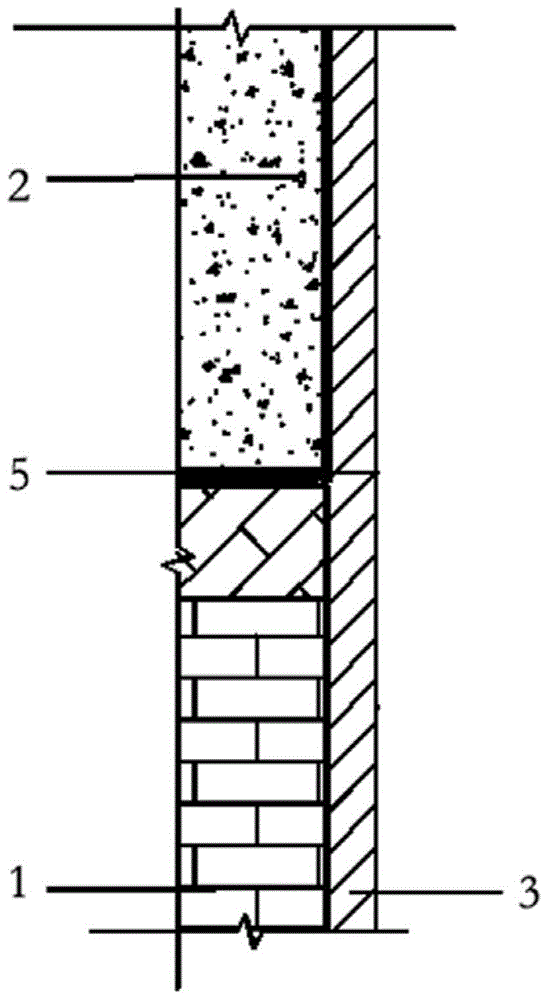

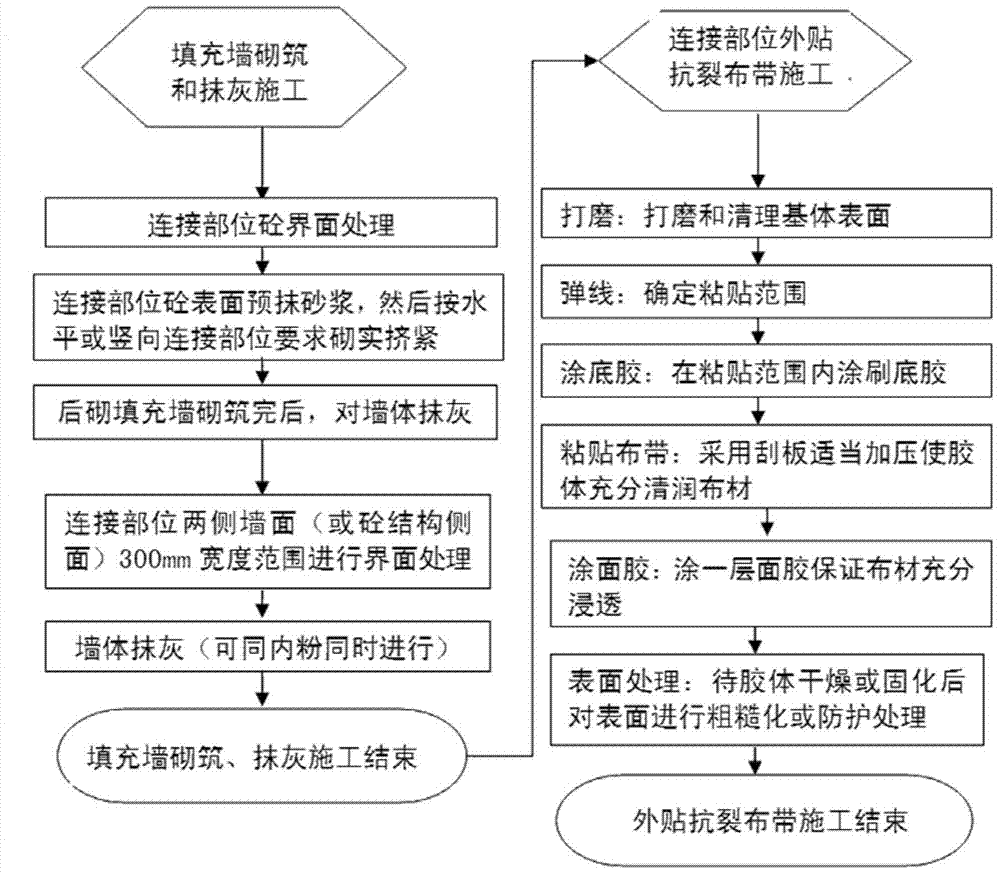

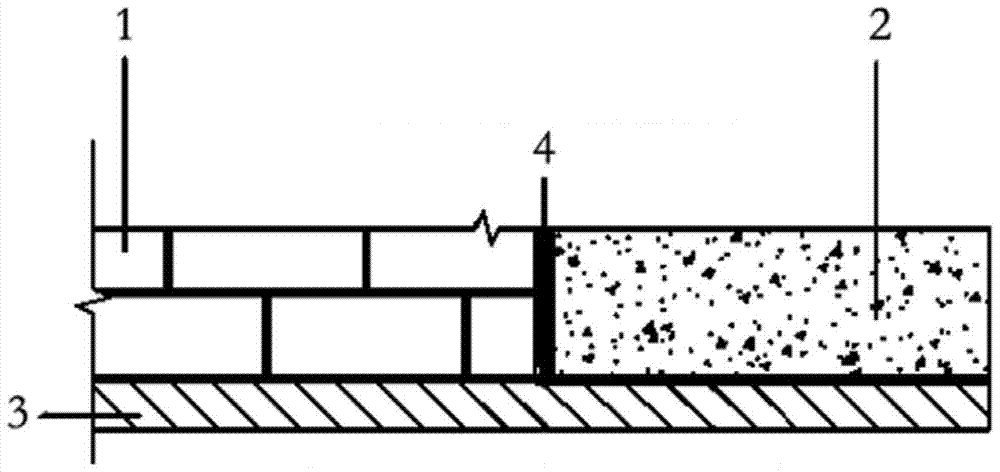

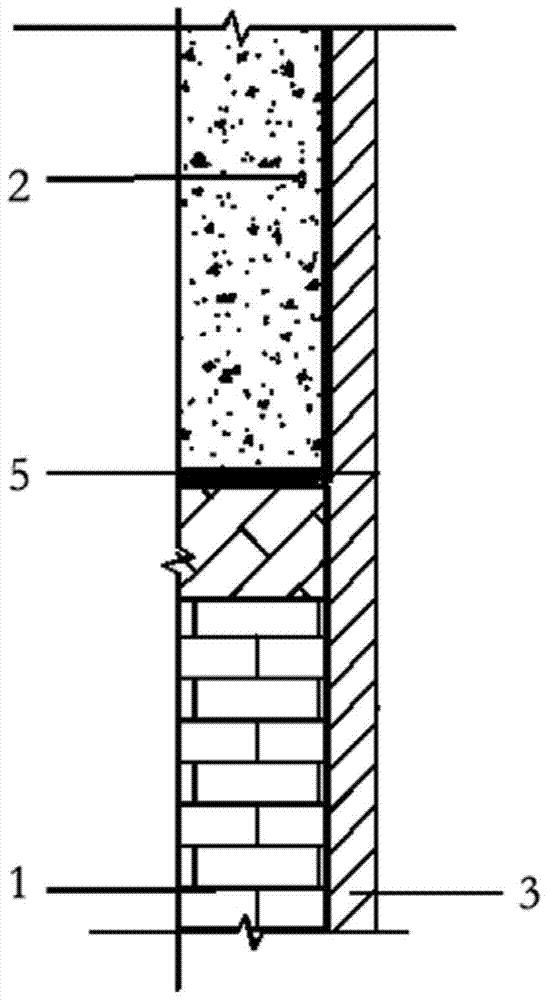

Method of preventing connecting part between concrete structure and rear filling wall from being cracked

The invention discloses a method of preventing a connecting part between a concrete structure and a rear filling wall from being cracked. The method is characterized by comprising the following steps: masonry construction of filling wall, plasterering construction of filling wall and construction of pasting anti-cracked woven belt outside the connecting part, wherein the process of the construction of pasting anti-cracked woven belt outside the connecting part comprises grinding and cleaning up the surface of a substrate, snapping a line on the surface of the substrate to determine the gluing scope of the woven belt, coating primer in the gluing scope, gluing the anti-crack woven belt and pressurizing the woven belt to be fully soaked by a scrapping plate, and coarsening or protecting the surface of the anti-crack woven belt after colloid is dried or solidified. The method provided by the invention has the beneficial effects of ensuring that the filling wall and a primary concrete structure are built and squeezed densely by improving and promoting an existing traditional masonry construction process; meanwhile, furthermore anti-cracking or effectively covering can be realized by adopting an effective external enhanced cloth through the combined action of two defense lines, the overall process is simple and the idealistic anti-cracking effect can be realized.

Owner:SHAANXI ACAD OF ARCHITECTONICS

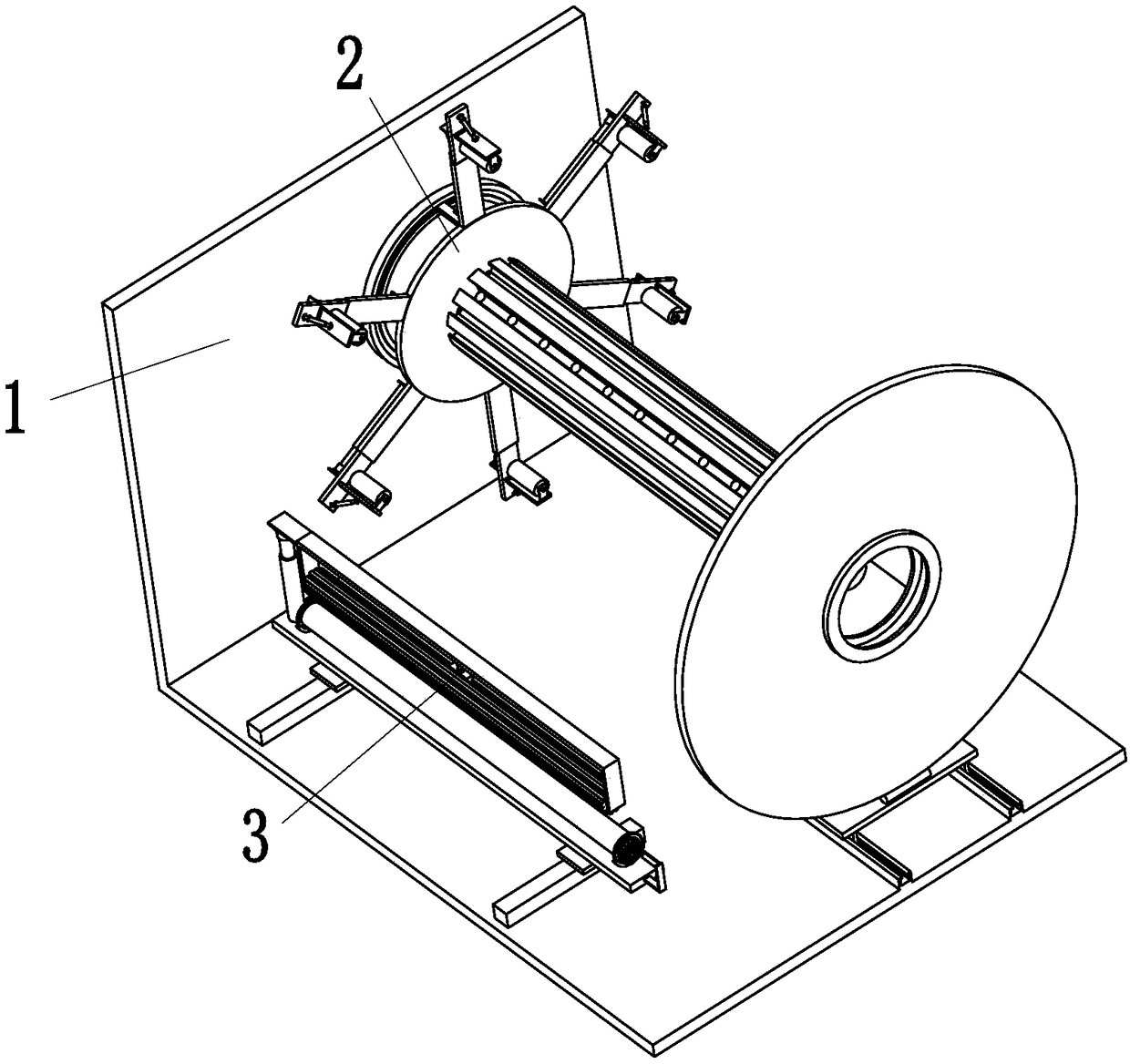

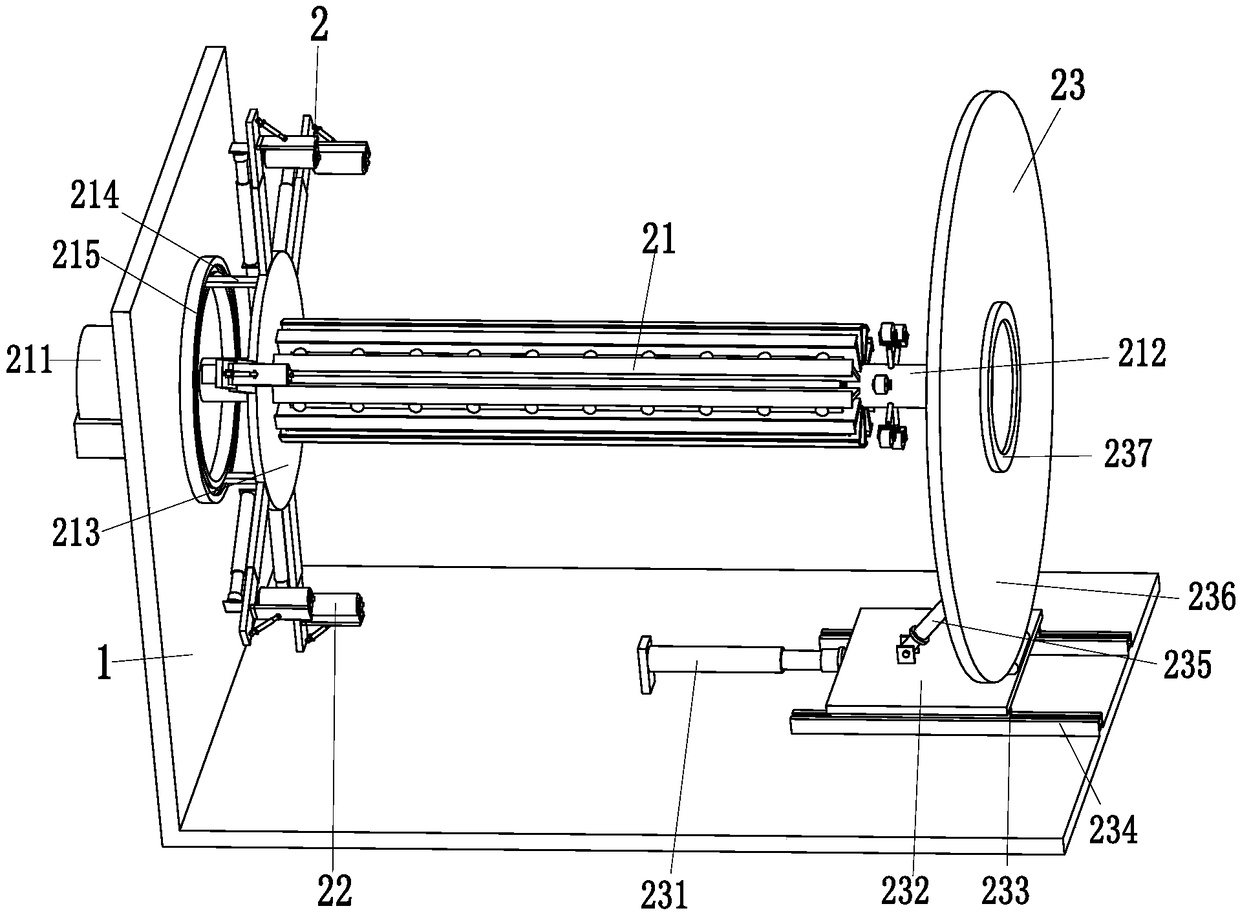

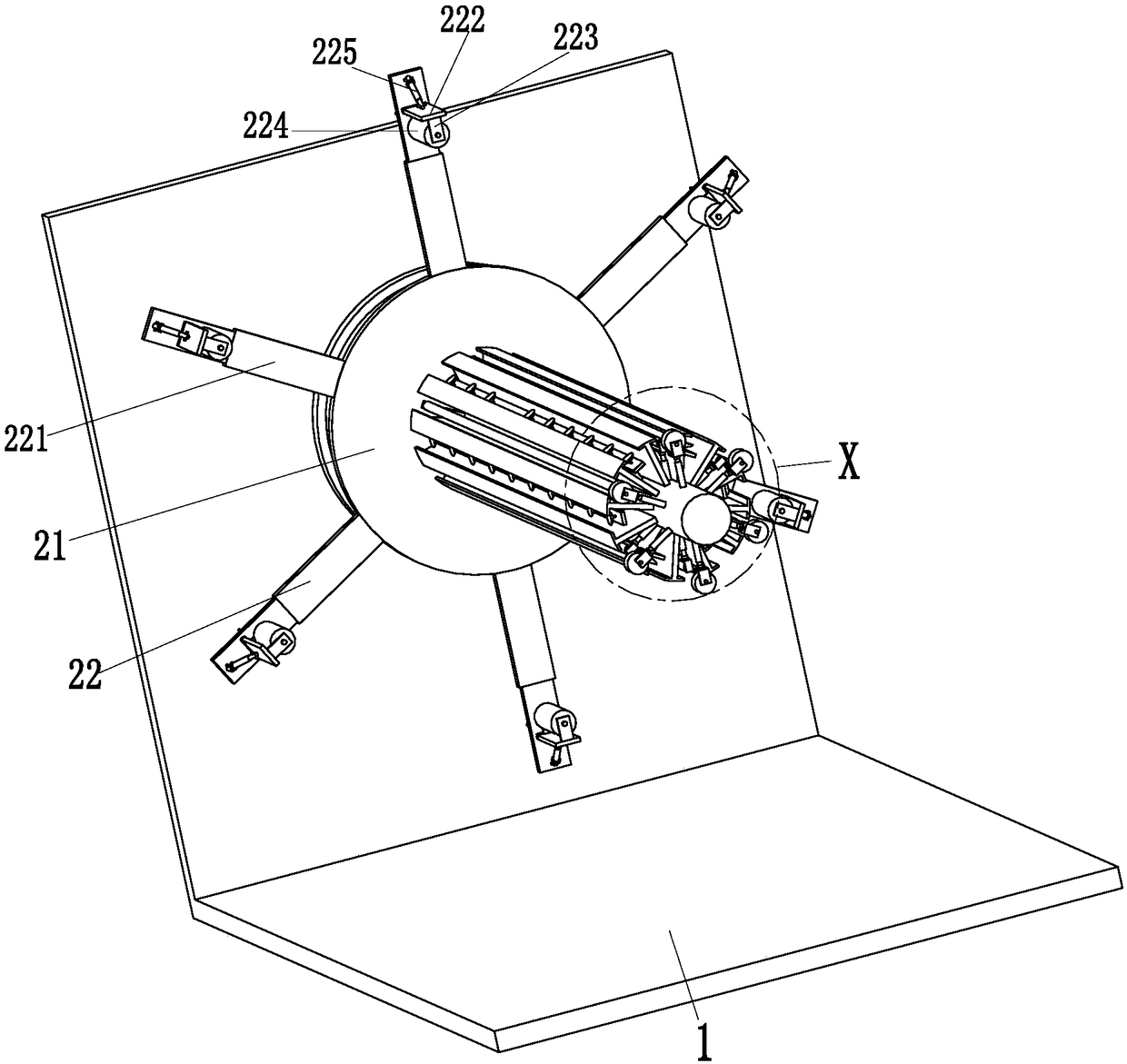

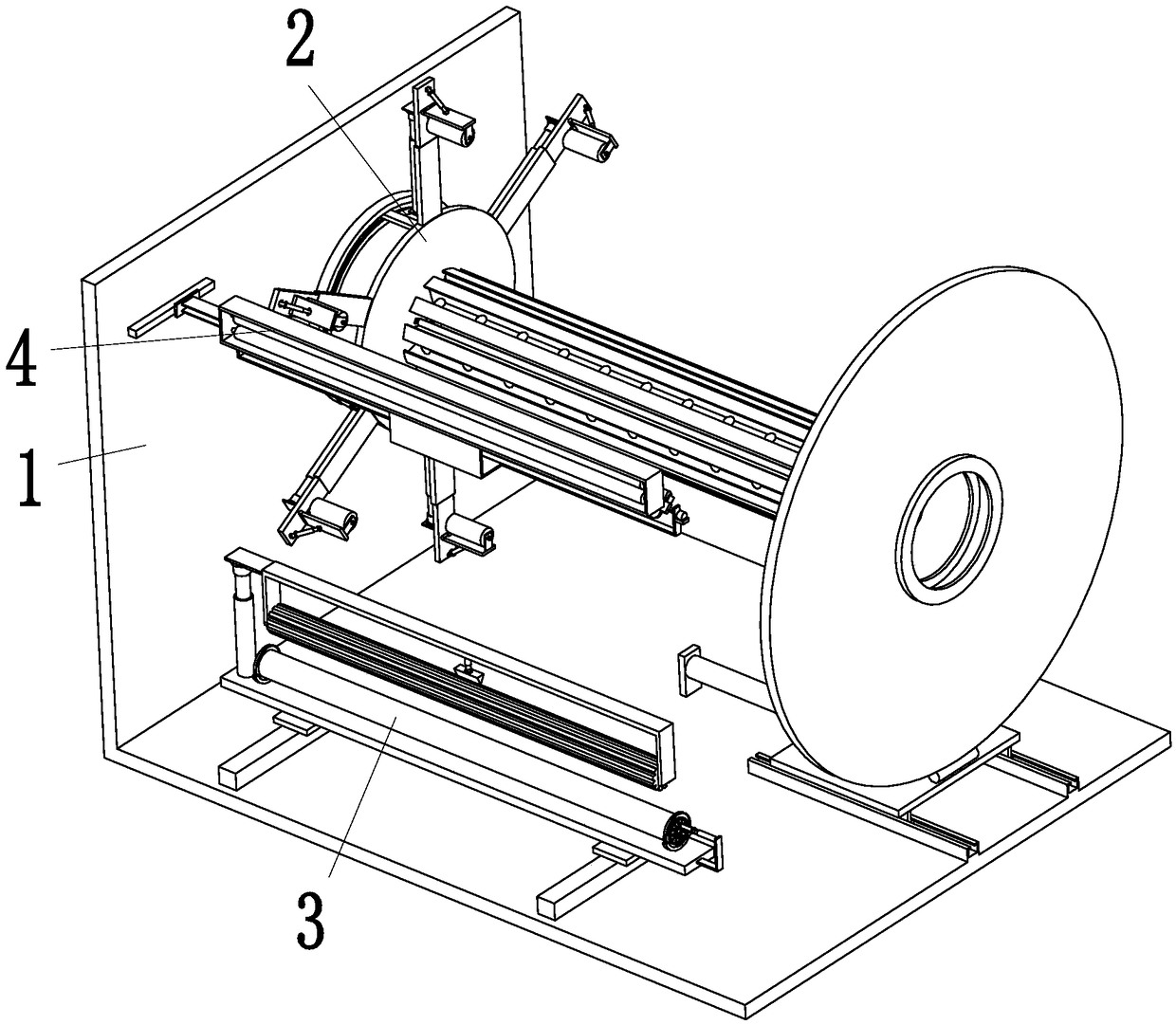

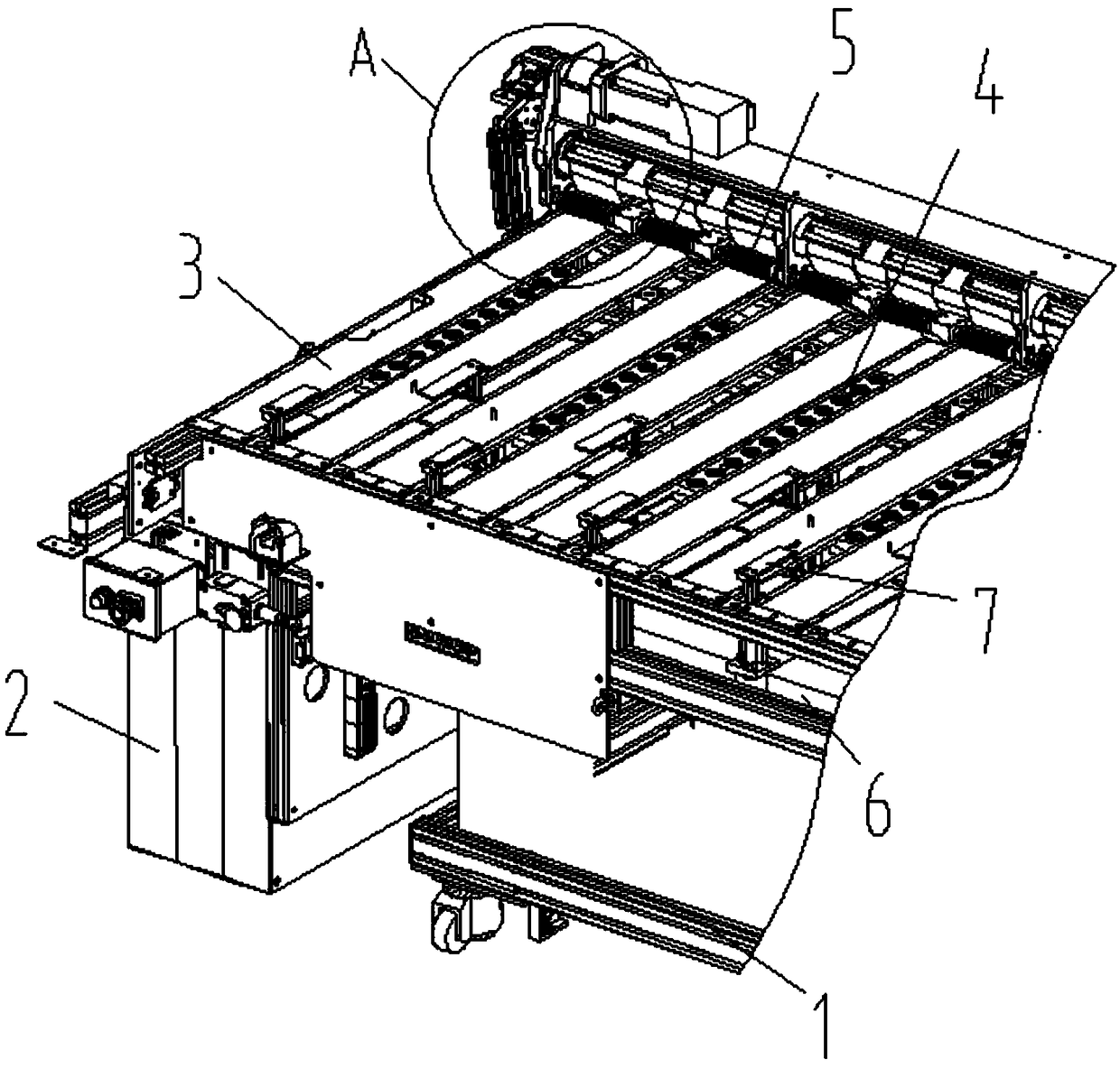

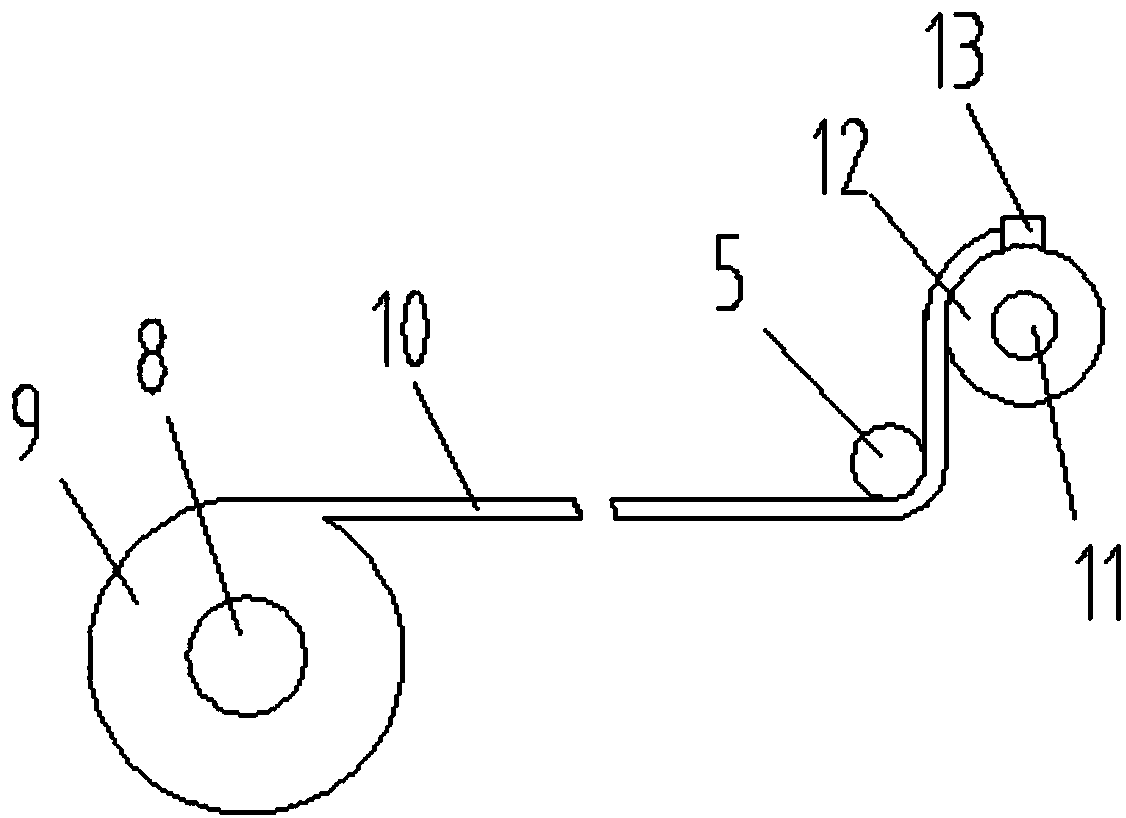

Corrugated-paper processing system

ActiveCN108910570ANot easy to roll tightReduce difficultyWebs handlingPulp and paper industryConductor Coil

The invention relates to a corrugated-paper processing system which comprises an L-shaped support, a roll device, a wrap-up device and a pull-out device. The roll device is mounted in the rear of theL-shaped frame, the wrap-up device is mounted at the bottom of the front end of the L-shaped frame, and the pull-out device is mounted on the front side wall of the L-shaped frame. By the arrangement,difficulties that wrapping up and pulling out of existing corrugated paper need a lot of workers to cooperate to complete since the process is tedious and complicated, the workers need to fix the head of the corrugated paper on a reel during wrapping up before manual rotation, the corrugated paper is less prone to winding up during rotation, manual winding is liable to damage the paper surface, pulling out the corrugated paper from the reel manually is laborious, pulling out efficiency is affected as the corrugated paper is less prone to rotation, the corrugated paper wrapped around the reelis easy to be fluffy and less prone to tight wrapping and manual cutting is needed, leading to long time consumption in the process, high labor intensity, low efficiency and the like can be solved.

Owner:东营市天泉包装印刷有限责任公司 +1

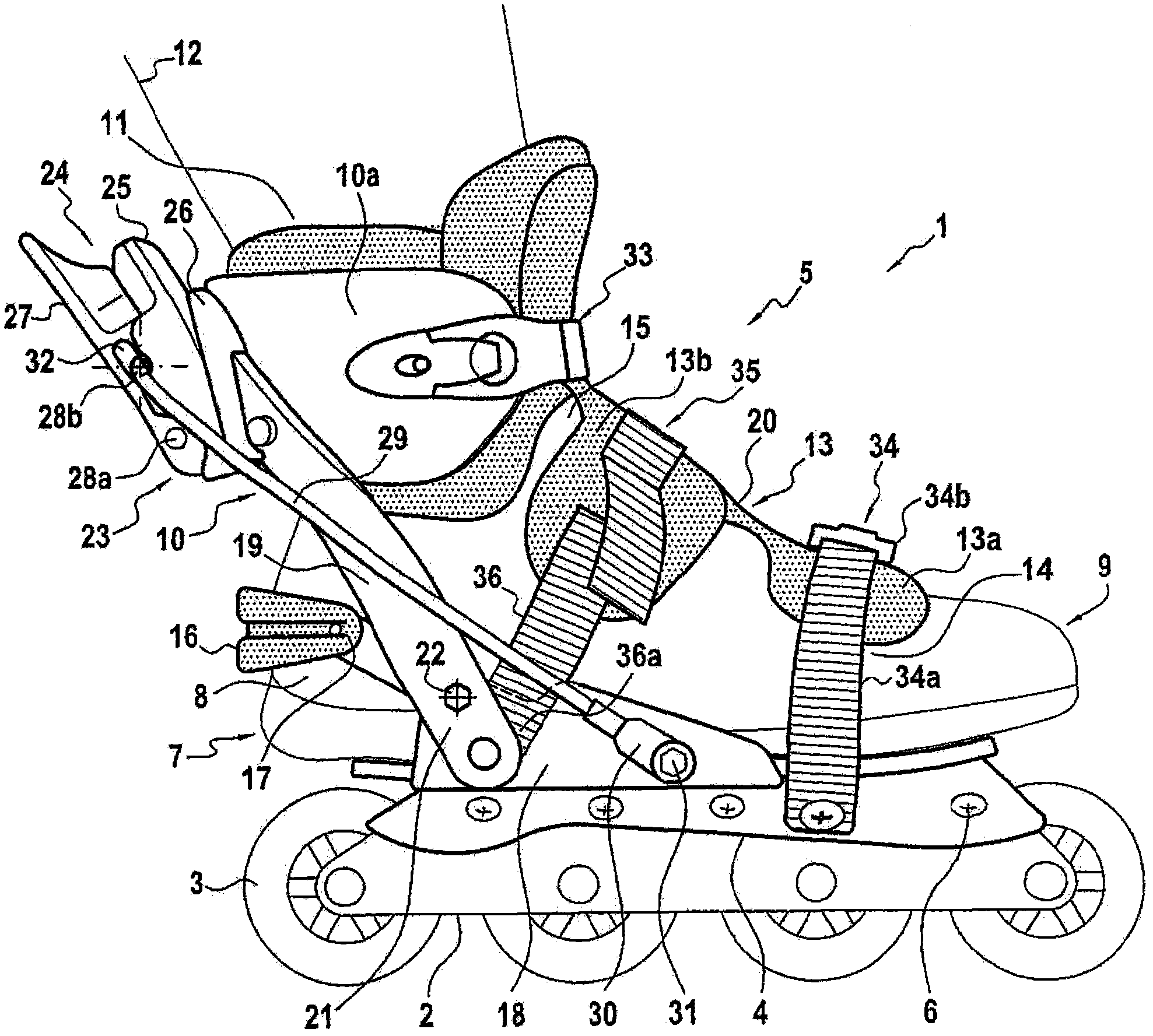

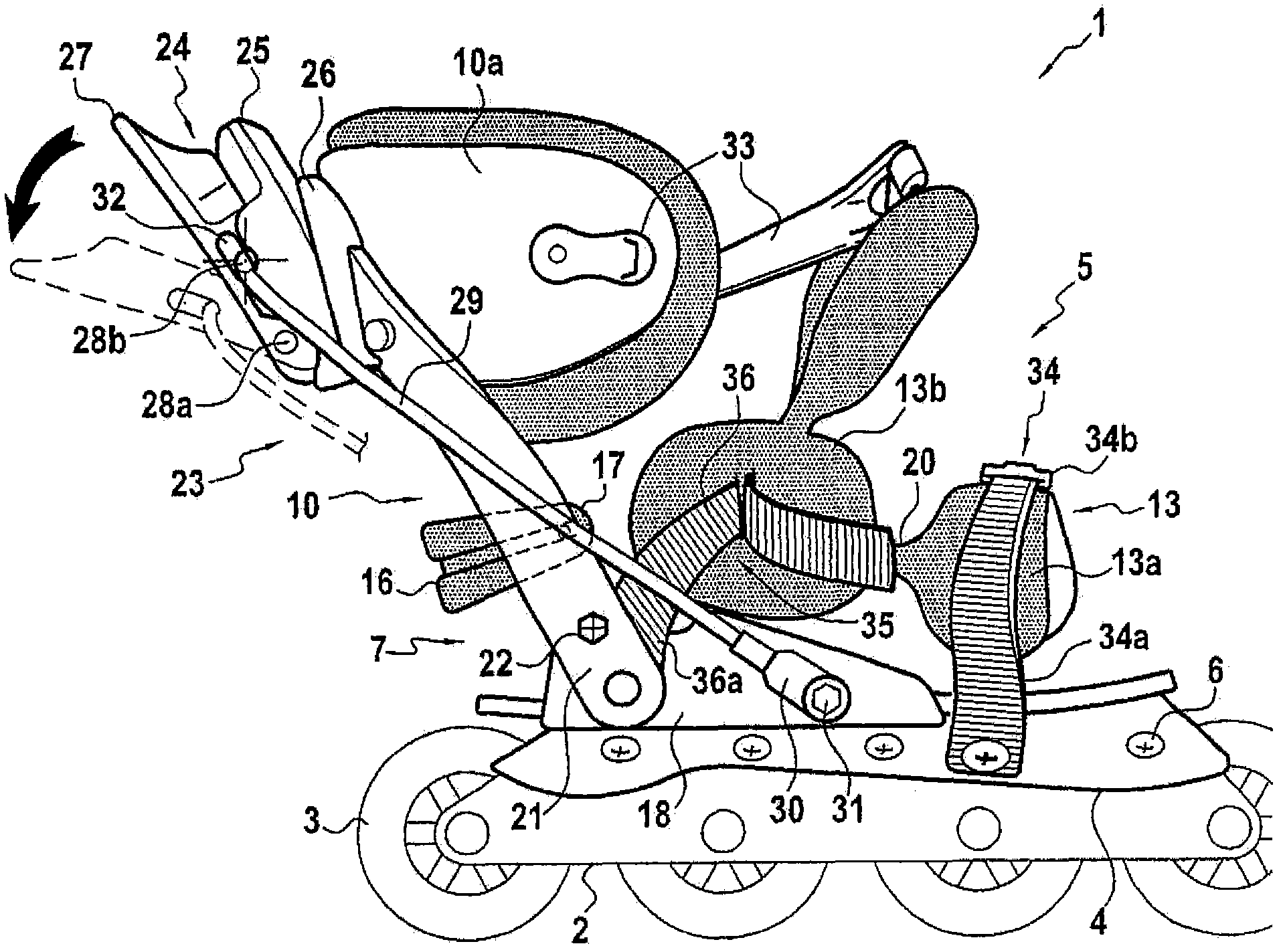

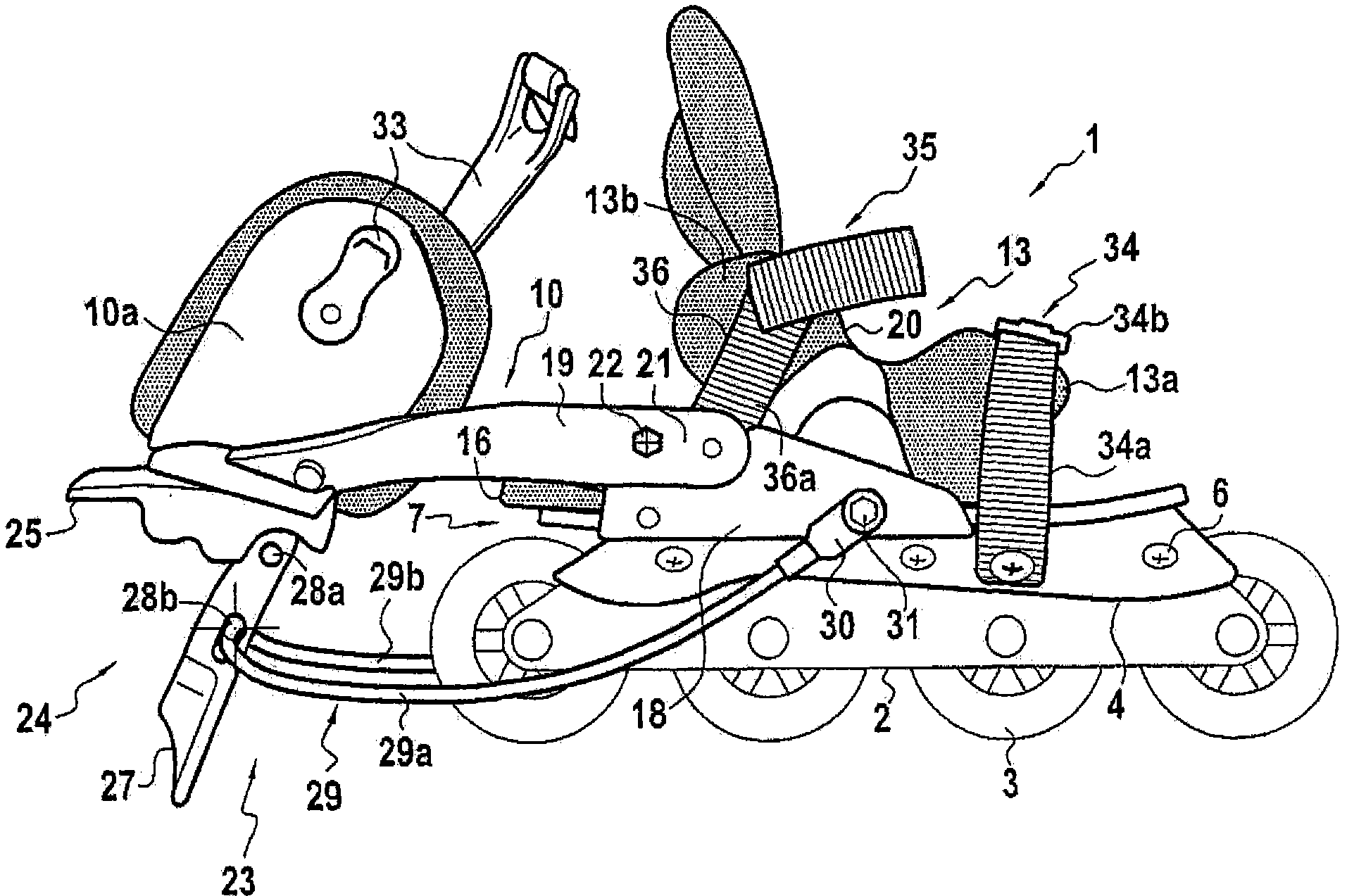

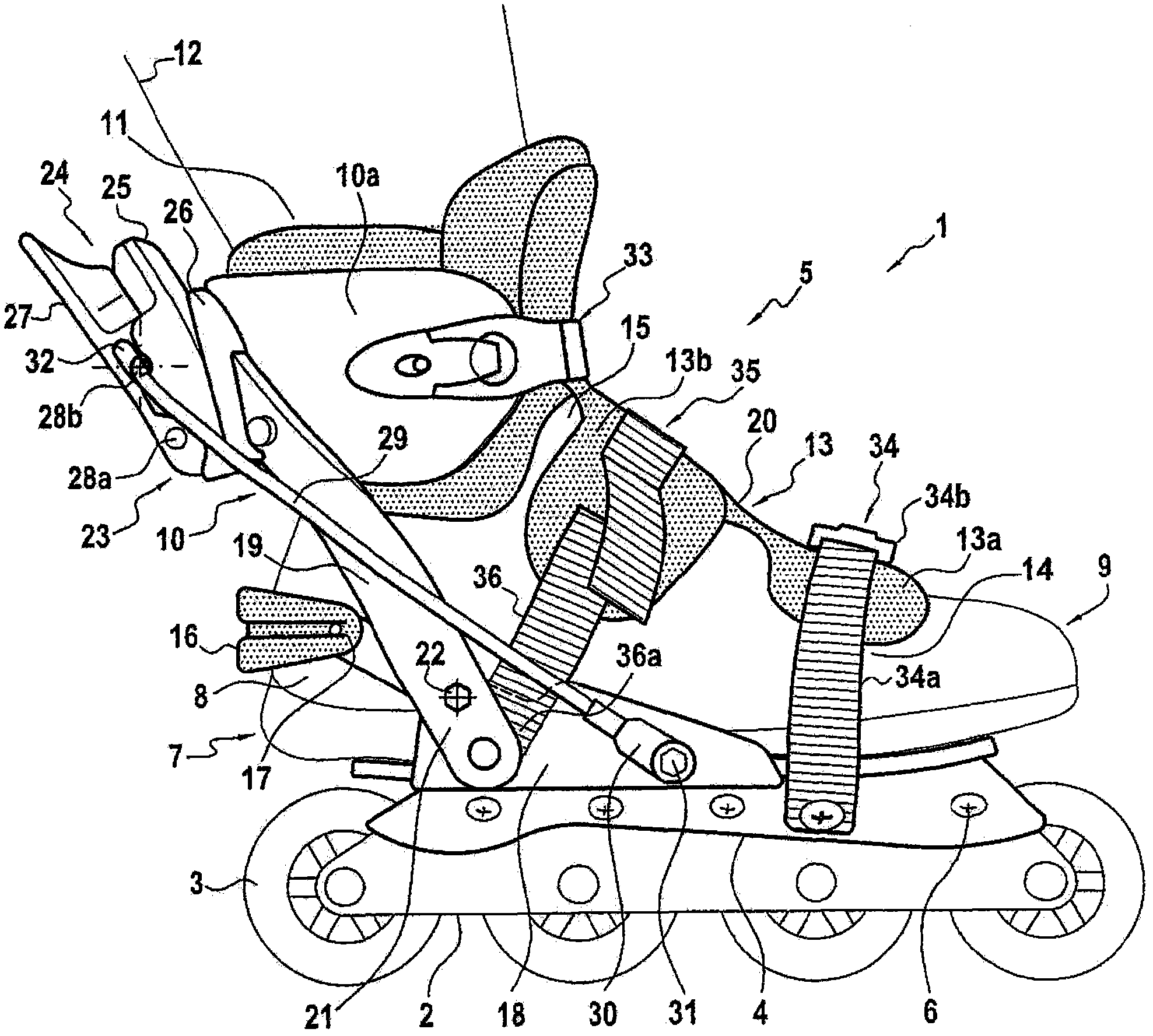

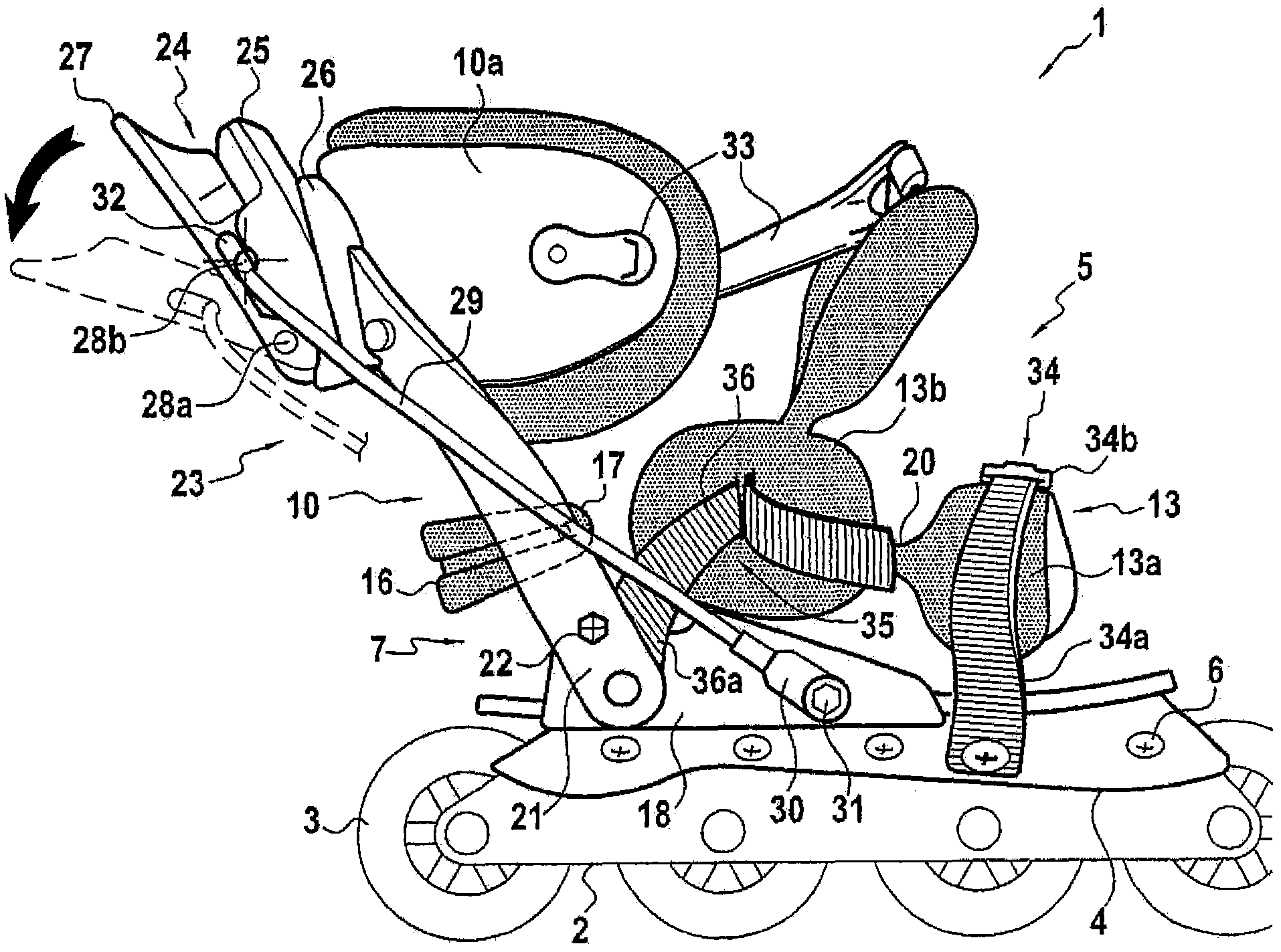

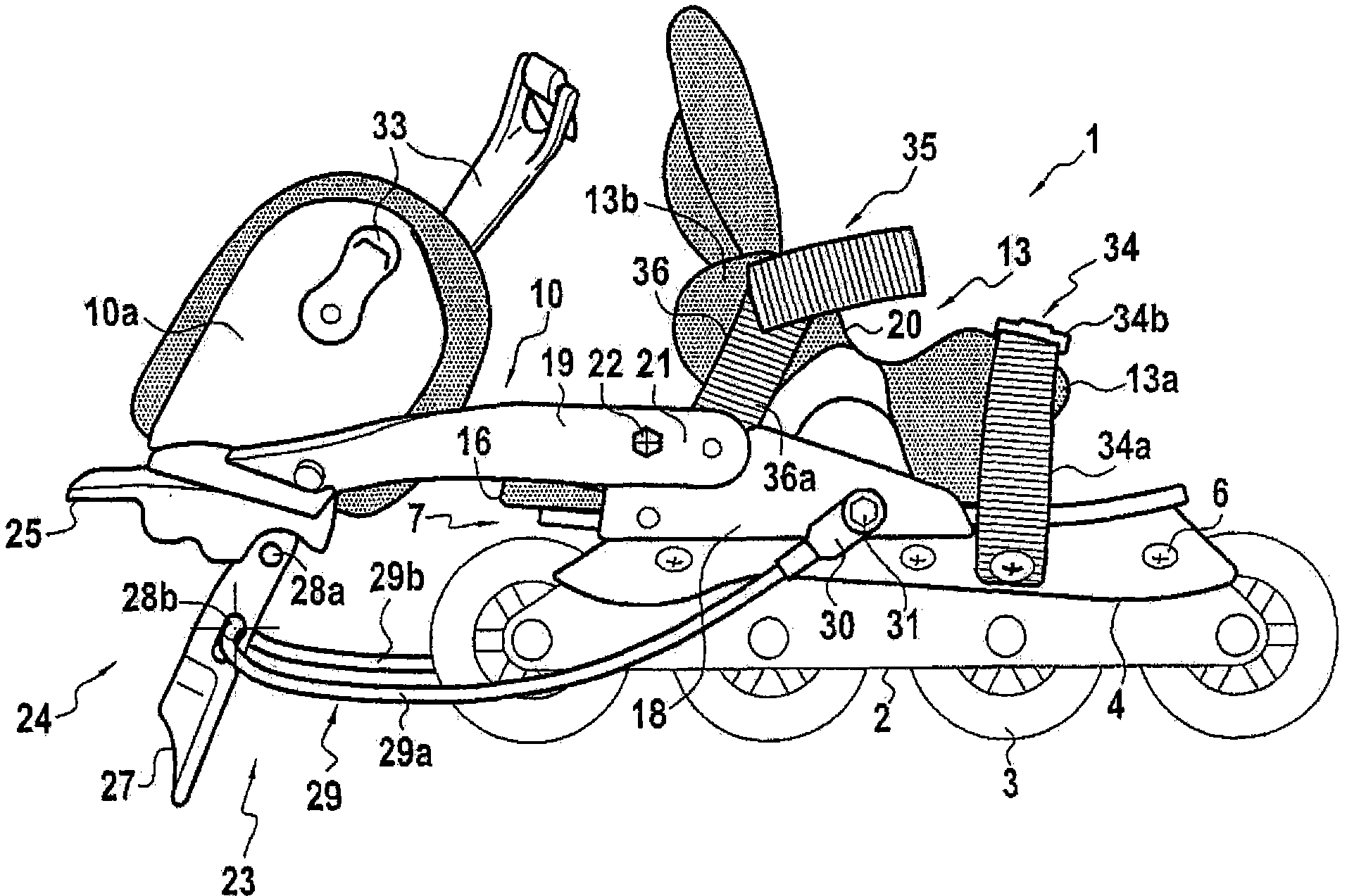

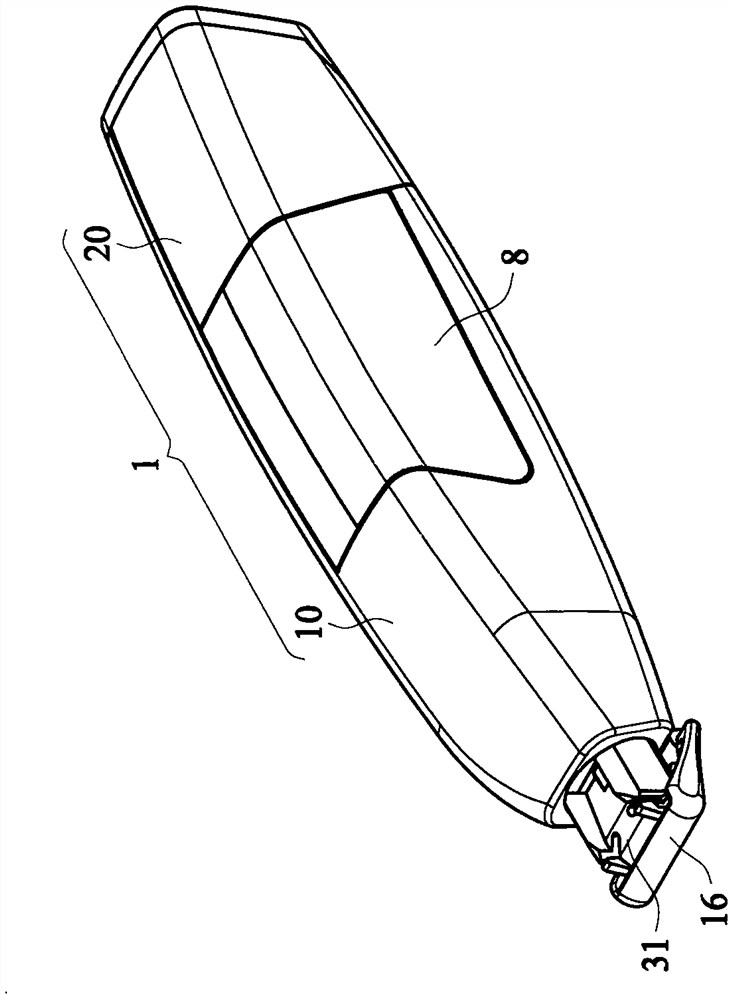

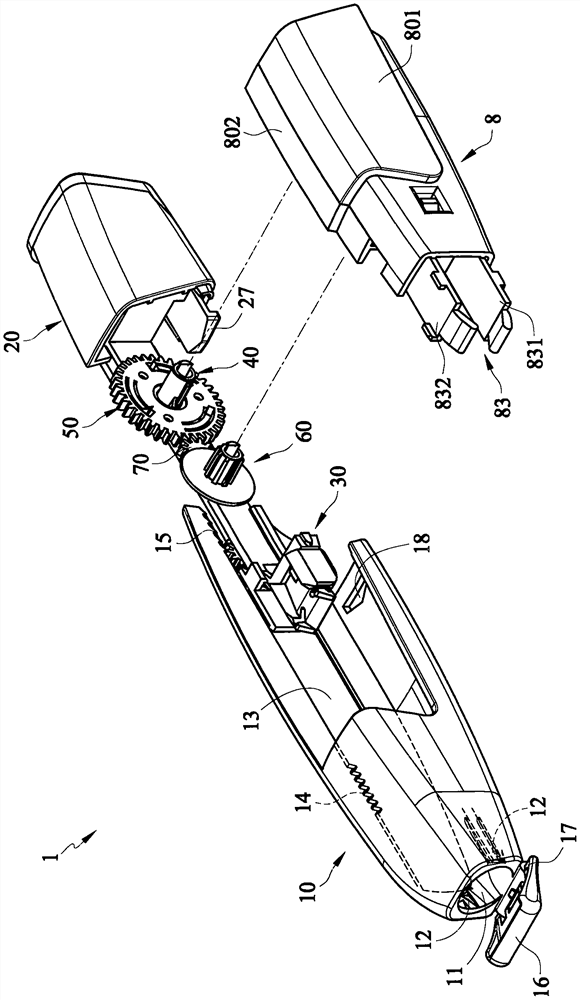

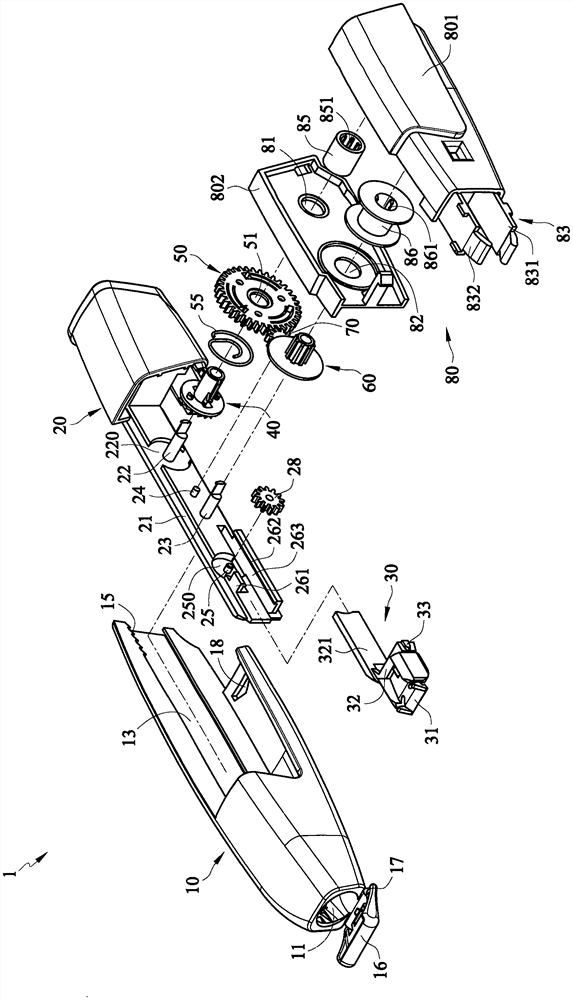

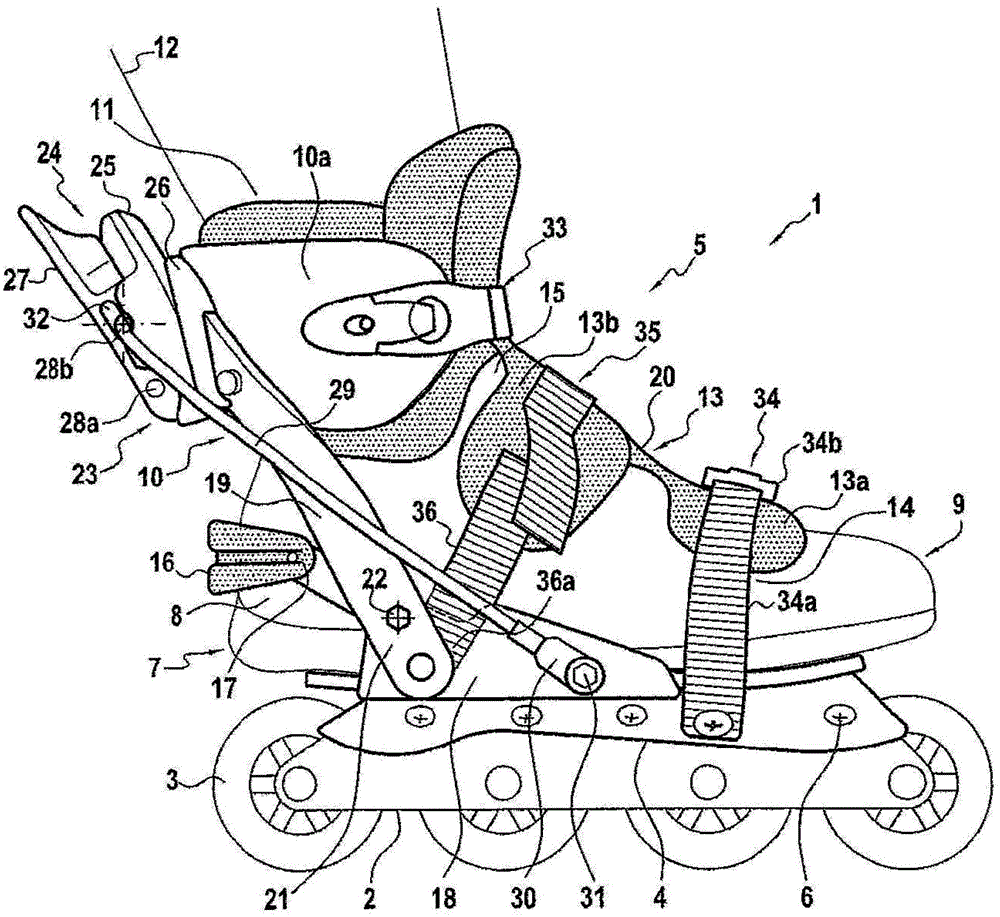

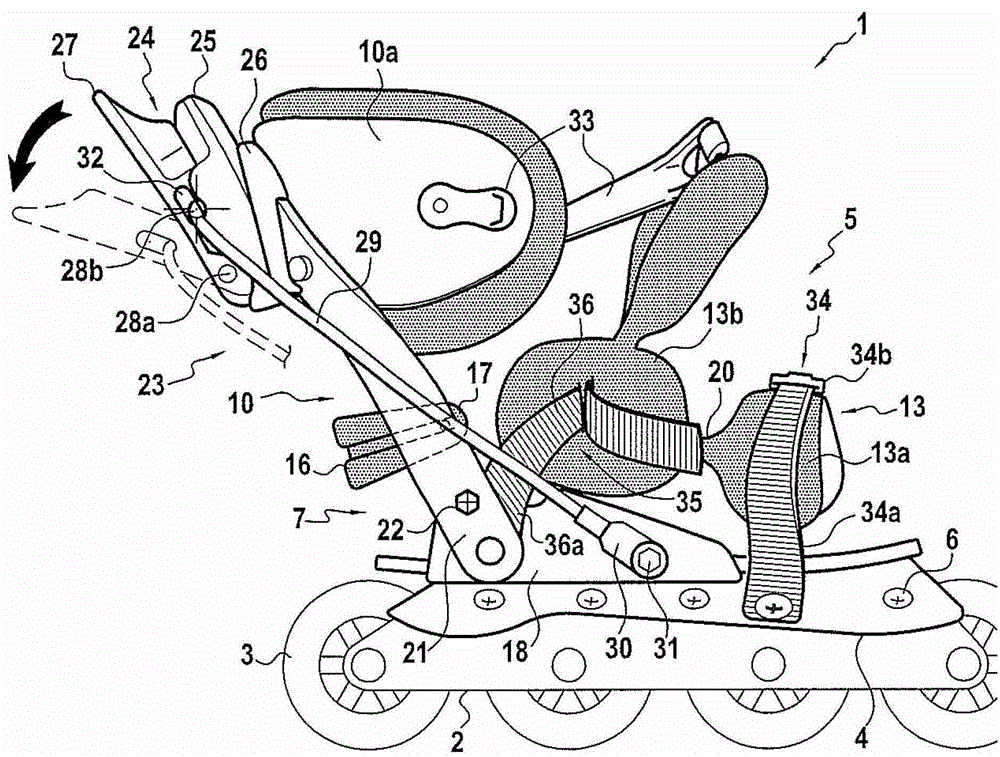

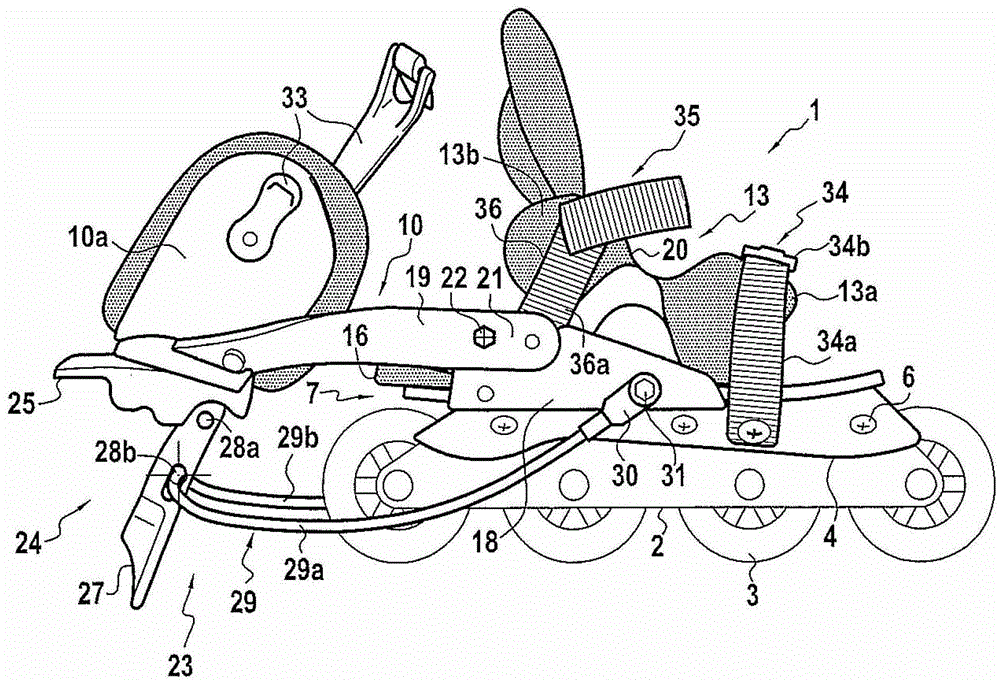

Fixing system of roller sports shoes

The invention relates to roller sports shoes (1), comprising a base (2), a supporting plate (4) and a wearing component (5). The wearing component is provided with an upper (10) pivoted backward with respect to the supporting plate. At least one elongated member (29) is disposed between the supporting plate and a tensioning system (23) disposed on the upper. The tensioning system is assembled in a manner that the elongated member is tensioned at a first position to lock the backward pivoting of the upper, and the elongated member is loosened at a second position to allow the backward pivotingof the upper. A coating device enabling a front upper to cover the back of the foot is disposed between the upper and the front upper.

Owner:DECATHLON SA

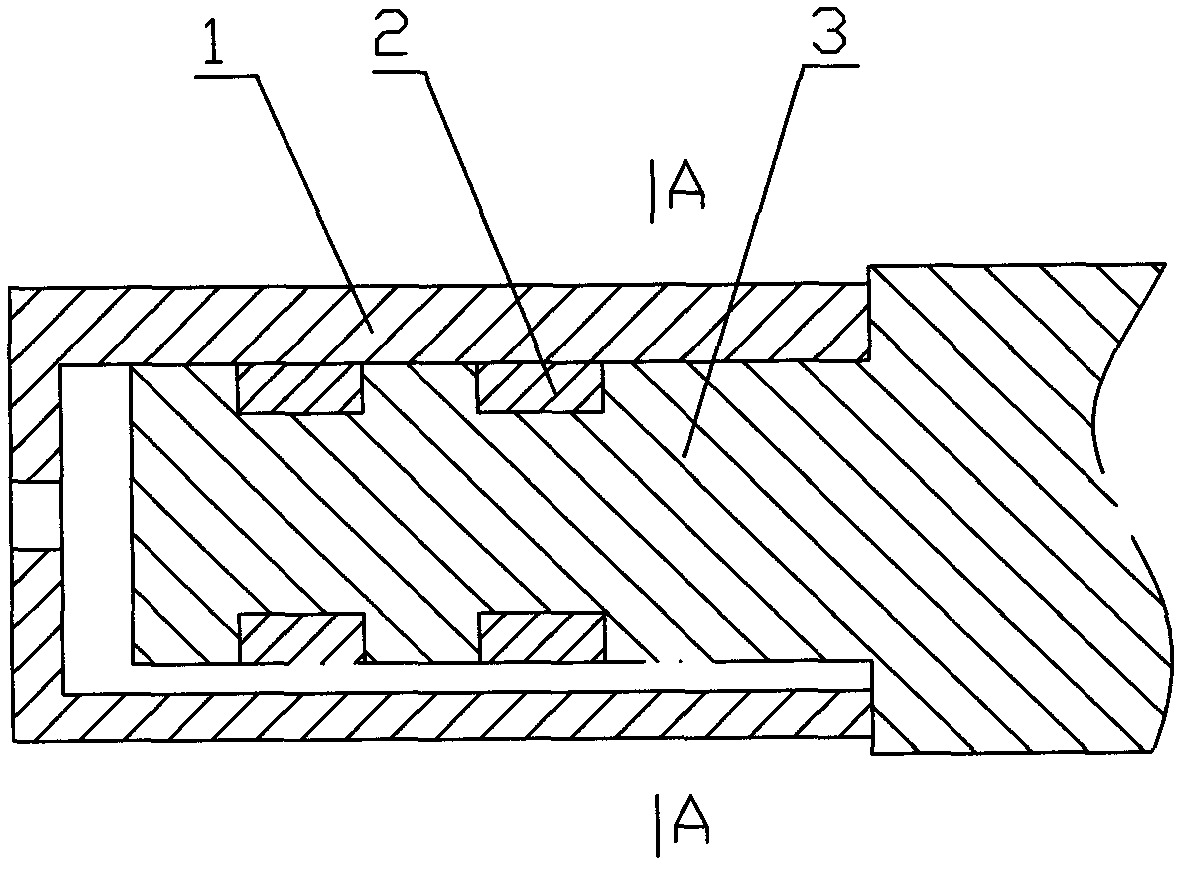

Protecting jacket of collecting ring of motor

InactiveCN102355076AMake sure it's tightSupports/enclosures/casingsArchitectural engineeringFront edge

The invention discloses a protecting jacket of a collecting ring of a motor, which relates to the tools used in the technology of motor production. The protecting jacket is a cylindrical body, an inner cavity of the protecting jacket is longer than a shaft end section, and the inner diameter of the protecting jacket is greater than the external diameter of the shaft end section; three radial rib plate strips extend inwards from an inner wall of the protecting jacket and distributed uniformly in a combination form, wherein the diameter surrounded by the front edges of the three rib plate strips is less than the external diameter of the shaft end section; and a bottom cover of the cylindrical body is centrally provided with a through hole. The protecting jacket of the collecting ring of the motor has the following advantage that: the protecting jacket and the shaft end section are sleeved together, which saves effort and ensures the tightness of the sleeved connection.

Owner:FUJIAN MINGUANG MOTOR

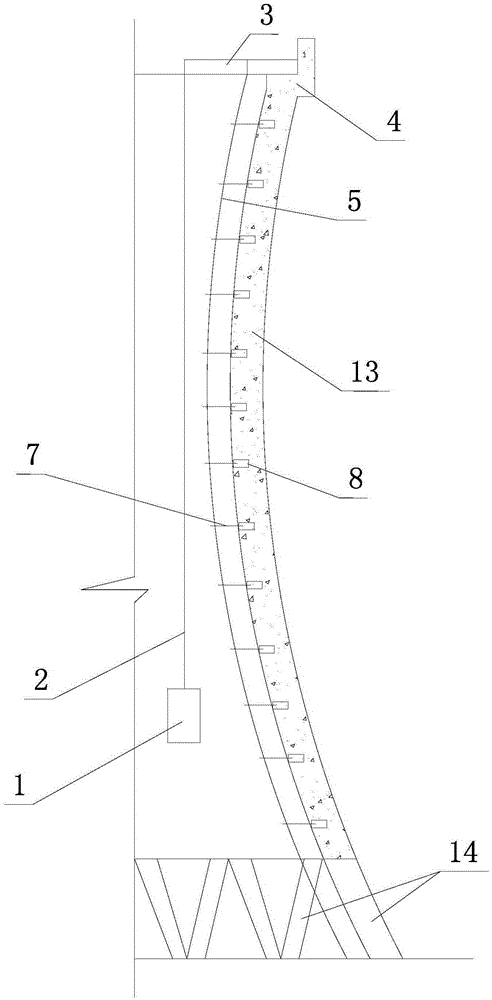

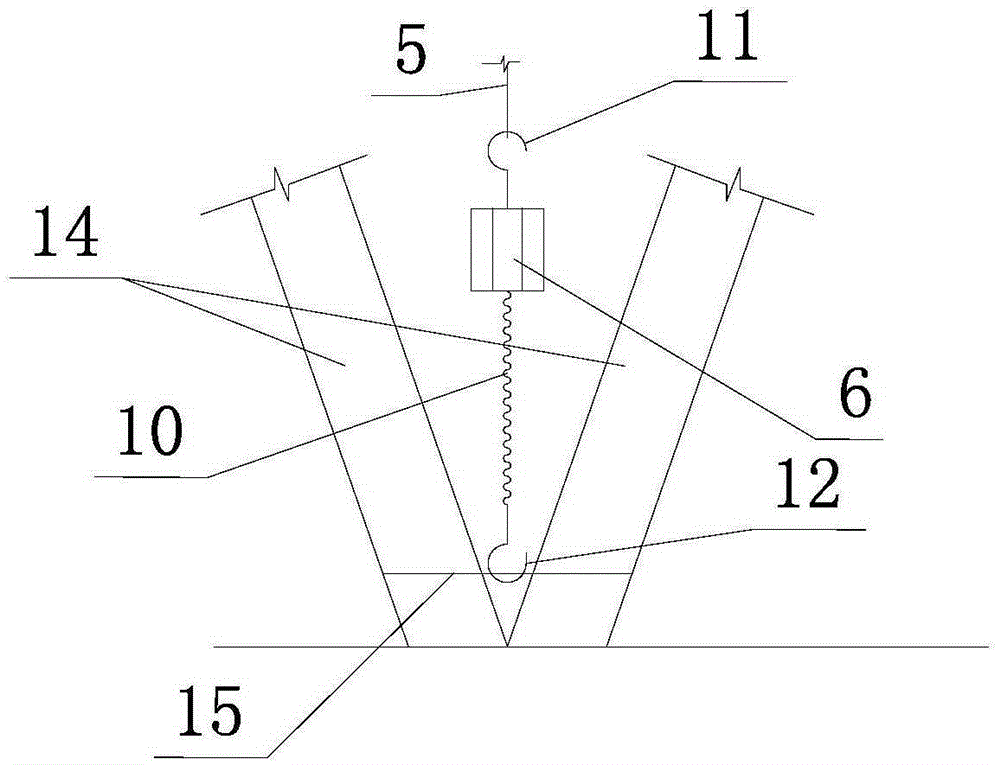

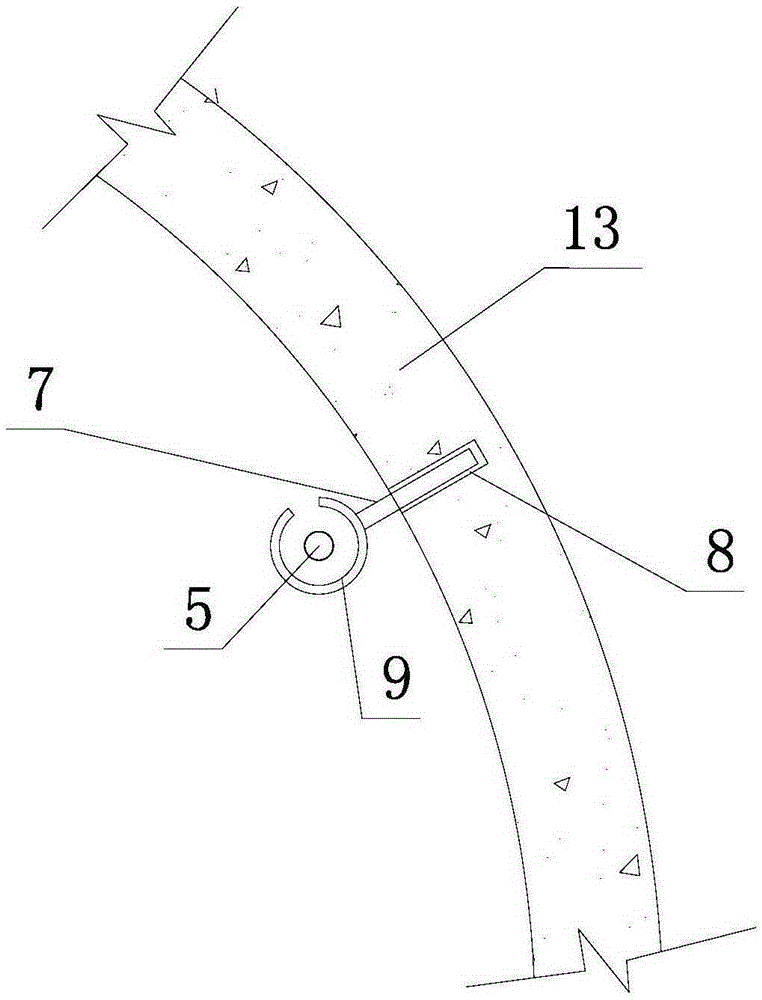

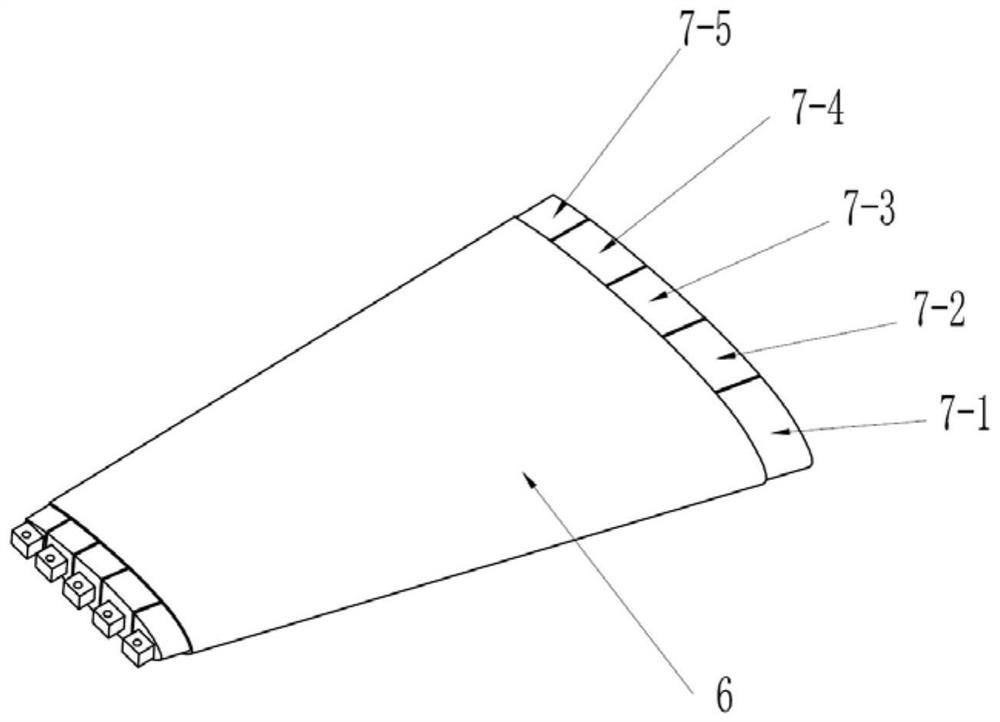

Hanging basket guiding device used for painting inner wall of hyperbolic-type cooling tower and painting method

InactiveCN105236318AReduce tensionLarge screw-in process timeLifting devicesBuilding material handlingCooling towerHanging basket

The invention discloses a hanging basket guiding device used for painting the inner wall of a hyperbolic-type cooling tower and a painting method. The device comprises a hanging basket (1), a bearing rope (2), a structural steel support (3) and guiding assemblies. The two ends of the bearing rope (2) are connected with the structural steel support (3) and the hanging basket (1) respectively. Each guiding assembly comprises a guide rail rope (5), a chain hoist, continuous wall ribs (7) and inner thread casing pipes (8). The continuous wall ribs (7) are screwed with the inner thread casing pipes (8). The guide rail ropes (5) are sleeved with lantern rings of the continuous wall ribs (7). The head ends of the guide rail ropes (5) are fixed to a coping ring beam (4). The tail ends of the guide rail ropes (5) are tensioned by the chain hoists. The method is characterized in that during painting, a cant hook is used for hooking the guide rail ropes (5) and drawing the guide rail ropes (5) back so that the hanging basket (1) can get close to the inner wall of the cooling tower (13). According to the hanging basket guiding device used for painting the inner wall of the hyperbolic-type cooling tower and the painting method, the painting process is fast and convenient to conduct, labor is saved, and consumables are reduced.

Owner:浙江省电力建设有限公司 +1

Fixing system of roller sports shoes

Owner:DECATHLON SA

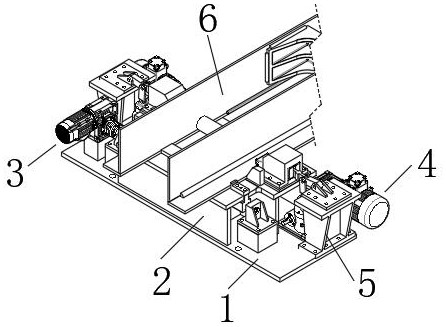

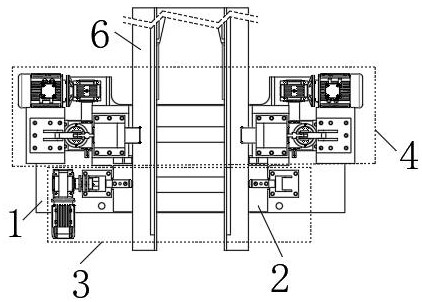

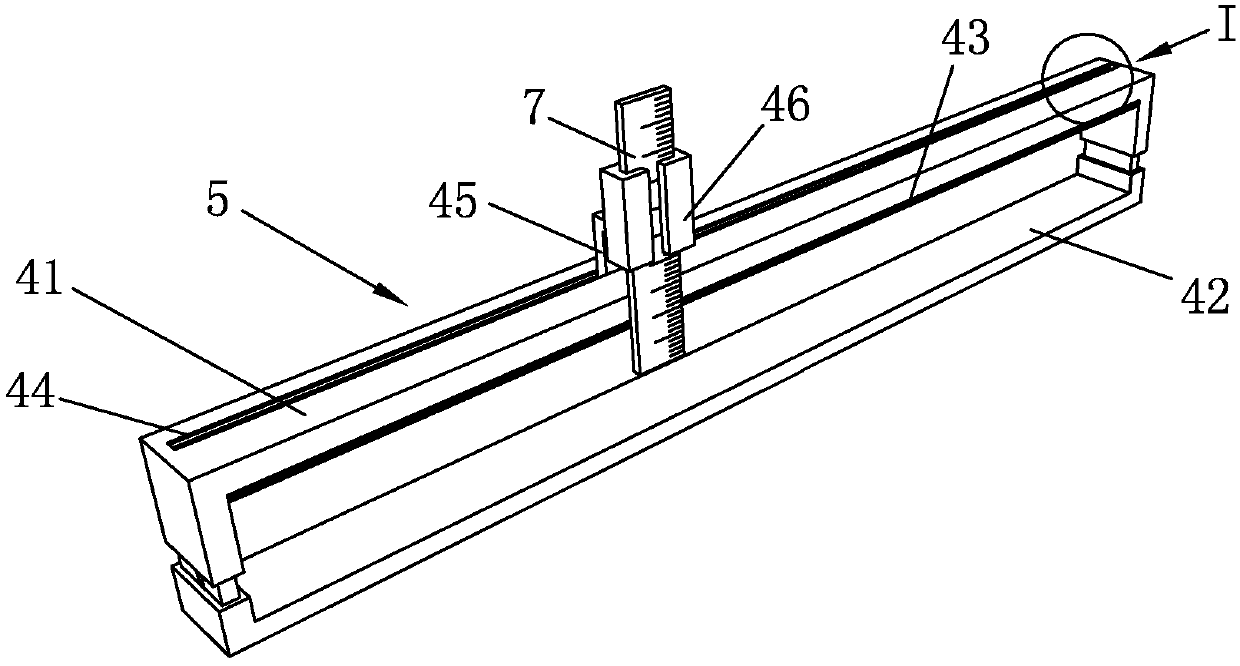

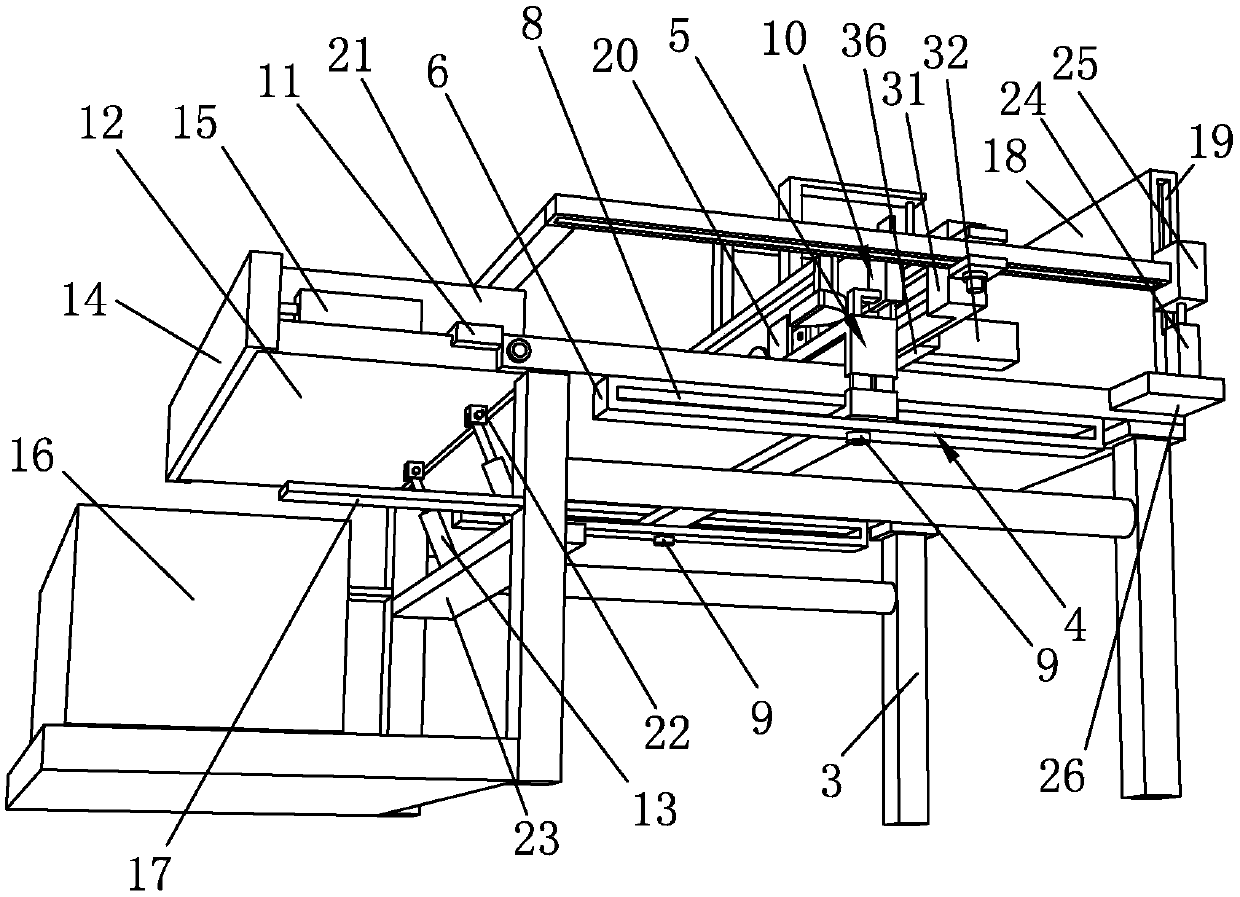

Automatic polishing chamfering machine of table board

ActiveCN106670933AAvoid slack strap situationsEnsure consistencyGrinding drivesBelt grinding machinesDistribution controlEngineering

The invention relates to an automatic polishing chamfering machine of a table board. The automatic polishing chamfering machine comprises a rack and a distribution control box. The rack is uniformly provided with polishing chamfering devices, each polishing chamfering device comprises an abrasive belt which is arranged on the rack and is upwards inclined from front to back, and a feeding mechanism matched with the table board and making the table board be fed in a front-rear horizontal manner is arranged in a gap between every two adjacent abrasive belts; and each feeding mechanism comprises a feeding device arranged on the rack and being capable of performing front-rear feeding, each feeding device is provided with a feeding clamper matched with the table board, and the feeding devices and the feeding clampers are connected to the distribution control box. According to the automatic polishing chamfering machine of the table board, the abrasive belts which are arranged in an inclined manner are adopted as the polishing chamfering devices in cooperation with the feeding mechanisms capable of making the table board be fed in a horizontal front-rear manner to achieve fixed-angle chamfering of the table board, chamfering efficiency is improved, the situation that abrasive belts are loose is avoided, and consistency of polishing chamfering is guaranteed.

Owner:广东顺德恒丽宝商用厨具有限公司

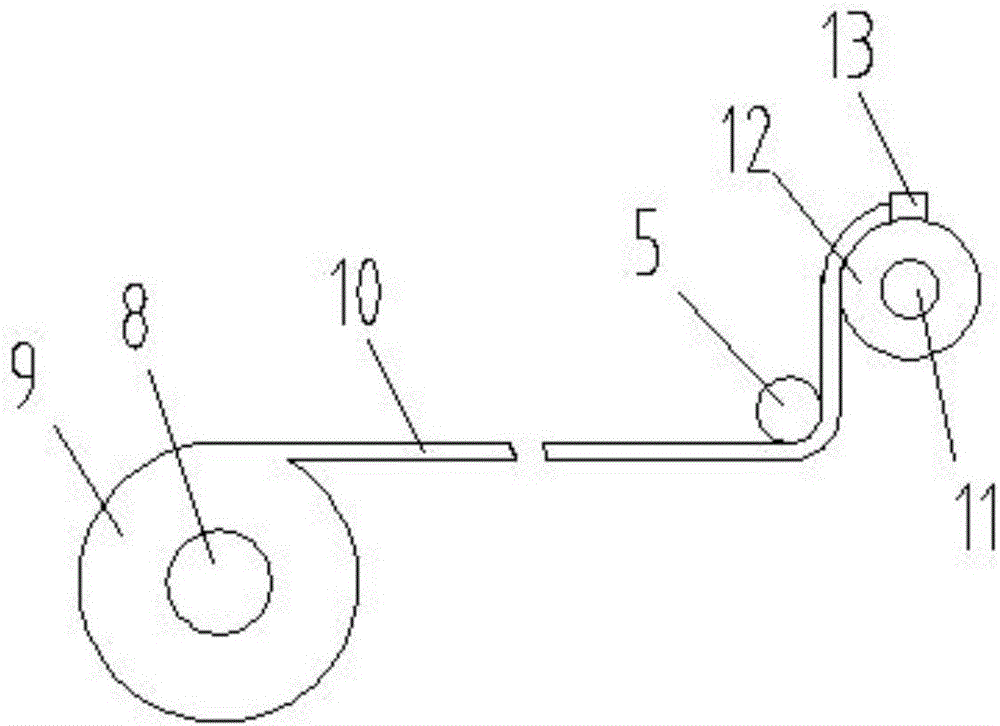

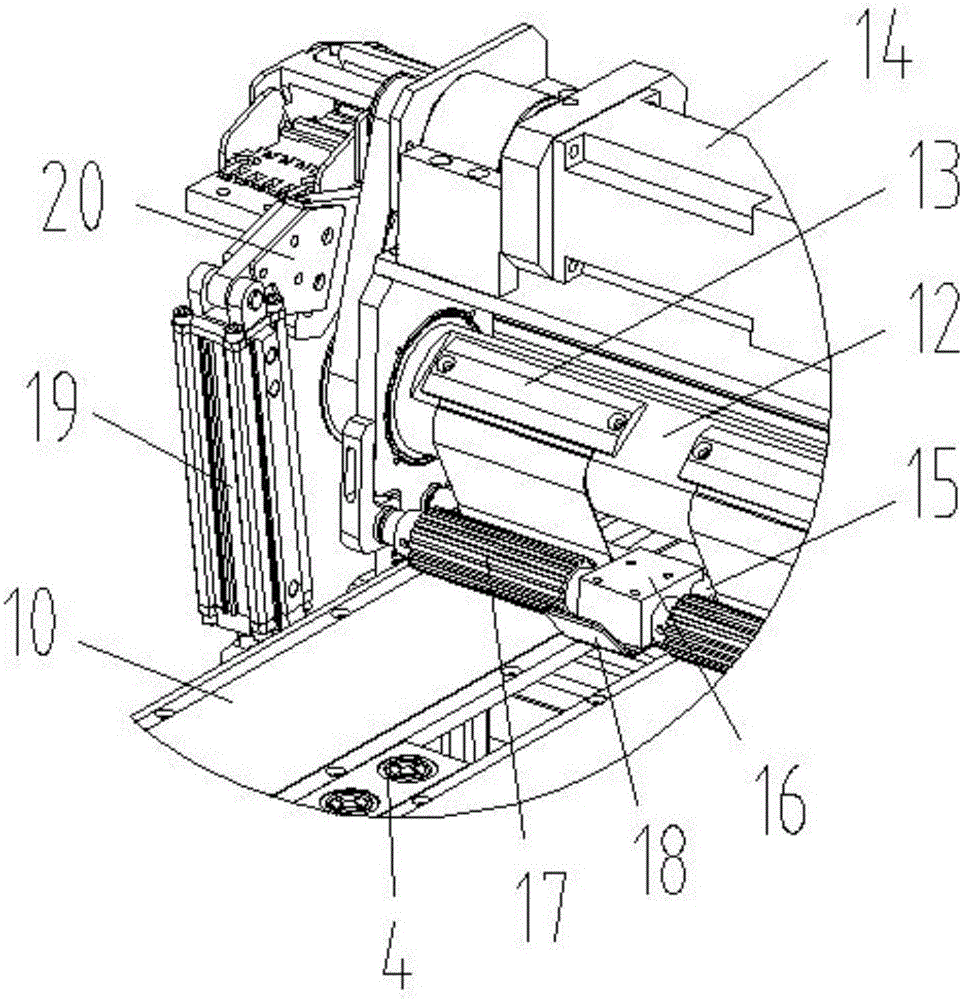

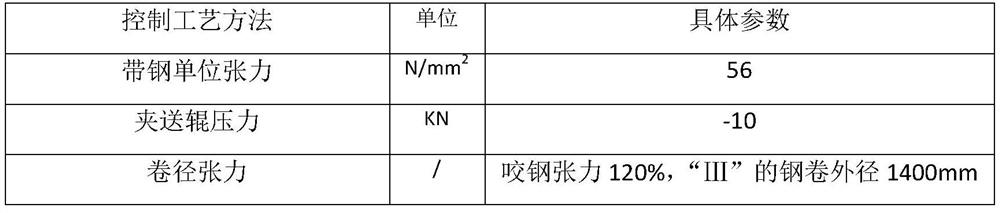

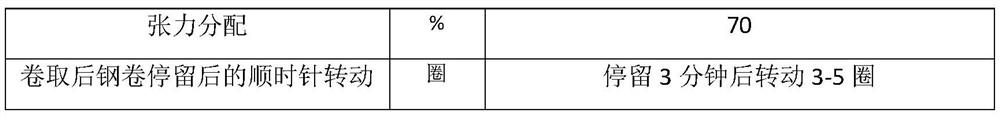

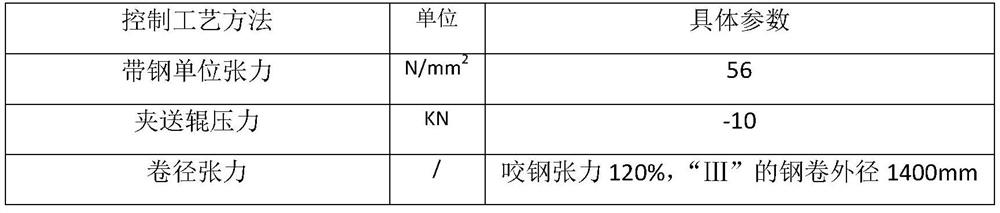

Method for eliminating 1.175 mm high-strength steel oval coiling existing in short-process production

ActiveCN112044956AEliminate Elliptical Roll DefectsAvoid the problem of increased deflectionTension/compression control deviceMetal rolling arrangementsEngineeringStrip steel

The invention discloses a method for eliminating 1.175 mm high-strength steel oval coiling existing in short-process production. The method comprises the steps of control of tension of strip steel, reduction of pressure of a pinch roll, adjustment of coil diameter tension and adjustment of tension distribution in the strip steel coiling process and clockwise rotation of a coiled steel coil after staying. By means of the method, 1.175 mm high-strength steel oval coiling existing in short-process production can be eliminated.

Owner:武汉钢铁有限公司

Tension regulating device for textile production

ActiveCN109335798AReasonable designExtended service lifeFilament handlingWebs handlingYarnEngineering

The invention discloses a tension regulating device for textile production. The tension regulating device comprises a regulating frame, a regulating roller set and a stentering assembly; the regulating frame comprises two fixing blocks, first supporting columns and second supporting columns; the regulating roller set comprises a first regulating roller set and a second regulating roller set whichare located at the left and right ends of a regulating rod set correspondingly; and the stentering assembly is located between the first regulating roller set and the second regulating roller set andcomprises a stentering roller and a mounting frame, regulating pressure springs sleeve the two ends of the stentering roller, and the lower ends of the regulating pressure springs are connected with the mounting frame. The tension regulating device is high in practicality and ingenious and reasonable in structural design, the structural size of the tension regulating device can be regulated according to the conveying requirements of different fabrics or yarns, thus the tension regulating device can be applied to conveying of the fabrics or the yarns with the different requirements, the using range of the tension regulating device is expanded, it is ensured that the fabrics or the yarns always keep a tightening state in the conveying process, and the conveying rate of the fabrics or the yarns are increased more conveniently.

Owner:SHENGZHOU WENDA TEXTILE CO LTD

Novel high-low voltage switch cabinet

InactiveCN113381301AMake sure it's tightPrevent looseningBus-bar/wiring layoutsSubstation/switching arrangement casingsLow voltageStructural engineering

The invention provides a novel high-low voltage switch cabinet. The novel high-low voltage switch cabinet comprises a cabinet body, an auxiliary unit, a bunching unit, an execution unit and a limiting unit. In the using process of an existing high-low voltage switch cabinet, due to the fact that wires connected with branch control switches connected in the high-low voltage switch cabinet are complex, the wires are inconvenient to overhaul in the later period, and after the complex wires are connected, the wires are prone to heating to induce fire hazards and the like; and after the wires are connected with the branch control switches, the wires are easy to shake under the influence of external force, as a result, the wires fall off and the use of the switch cabinet is influenced; the wires are fixed by wire clamps at present, so that the stability of the internal wires is ensured, the outer walls of the wires are easy to wear and crack due to excessive friction between the wires and the wire clamps when the wires are fixed by the wire clamps, as a result, the quality structures of the wires are influenced.With the novel high-low voltage switch cabinet adopted, the above problems can be solved.

Owner:JIANGSU ZHONGMENG ELECTRIC EQUIP

Automatic centering clamping mechanism with self-locking function

PendingCN112157611AGood self-lockingSelf-locking purposeWork holdersElectric machineryStructural engineering

The invention relates to the technical field of machining, in particular to an automatic centering clamping mechanism with a self-locking function. The automatic centering clamping mechanism with theself-locking function comprises a centering clamping machine base, a supporting plate is welded to the centering clamping machine base, a centering assembly is arranged at the outer end of the supporting plate, and clamping assemblies are arranged on the two sides of the supporting plate. Power of the automatic centering clamping mechanism with the self-locking function is completely from a motor,the power is transmitted to a connecting rod mechanism through a worm gear and a worm in the clamping process, then the connecting rod mechanism transmits the power to a pressing wedge block, a workpiece is pressed through the pressing wedge block, the worm gear and the worm have good self-locking performance, the self-locking purpose is achieved, the connecting rod mechanism realizes self-locking through a dead point and ensures that the pressing force becomes larger and larger, enough force is provided, and in-place pressing is ensured.

Owner:江苏赛仑特智能装备有限公司 +1

Cutting machine for hardware fitting production

ActiveCN109623022AGuaranteed structural strengthAvoid collection impactShearing machinesShearing machine accessoriesEngineeringUltimate tensile strength

The invention discloses a cutting machine for hardware fitting production. The cutting machine comprises a cutting table and a cutting head set; the cutting table is provided with a positioning module; the positioning module comprises a positioning clamping plate, a slide frame and a positioning staff; a placing table is arranged at the front end of the cutting table, and is hinged with the cutting table; a collecting box is arranged under the placing table; and the cutting head set comprises a vertical adjusting module, a transverse adjusting module, a longitudinal adjusting module and a cutting head. Through a positioning module, the precise positioning between the cutting head and a workpiece cutting position is realized, so that the cutting precision is effectively improved, and the cutting error rate is reduced; the positioning module also can be used for realizing pressing and positioning of workpieces, so that the cutting precision is further improved, and the workpieces are prevented from moving in the cutting process; meanwhile, the cut workpieces can be temporarily placed through the placing table; a rotating cylinder is matched to realize automatic collection of the workpieces; and the workpieces accumulated on the placing table are automatically put in the collecting box for collection, so that the manual operation intensity is effectively relieved.

Owner:南通旭之初新材料科技有限公司

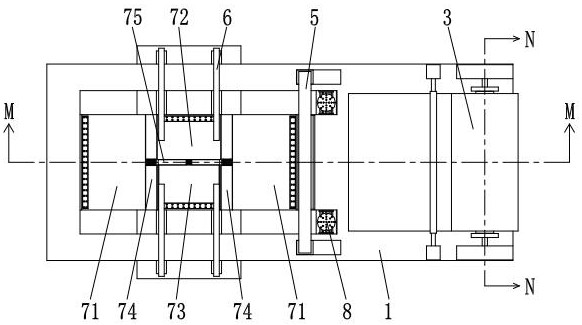

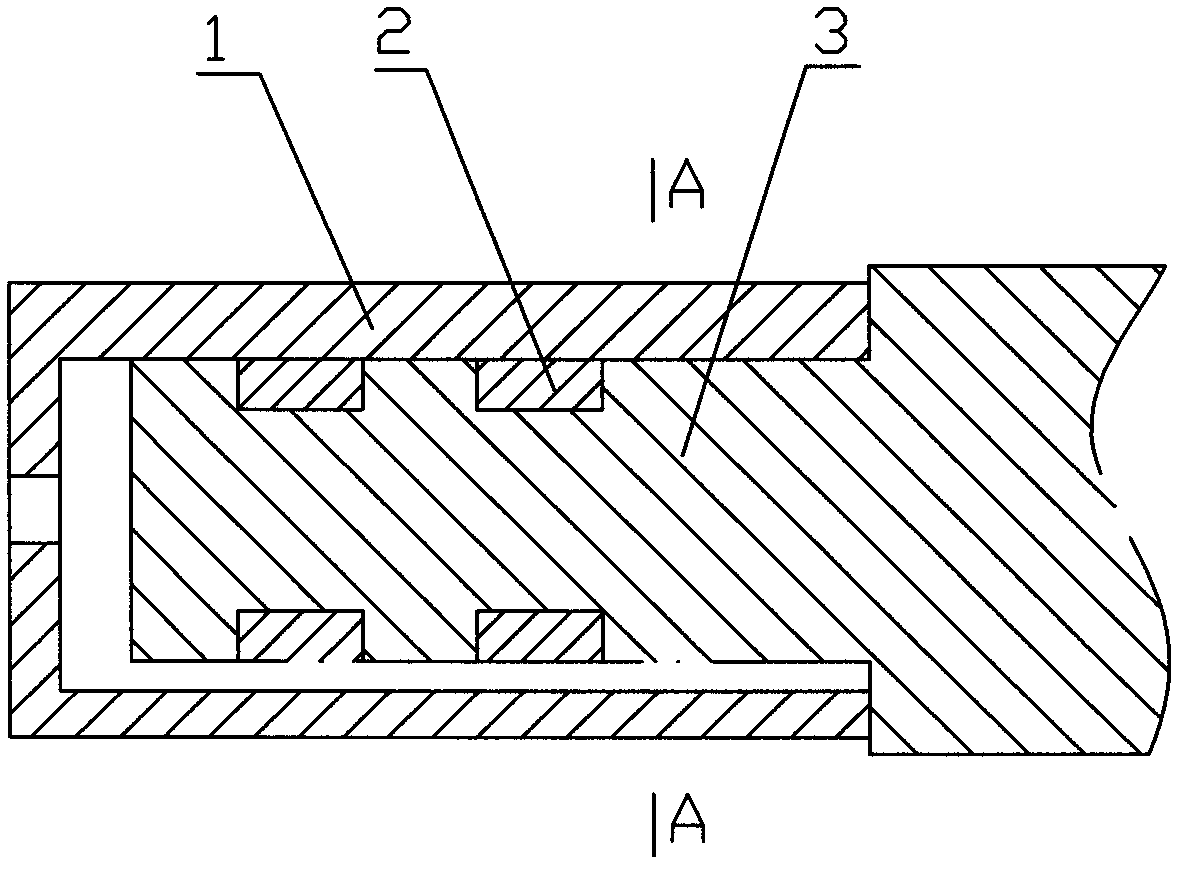

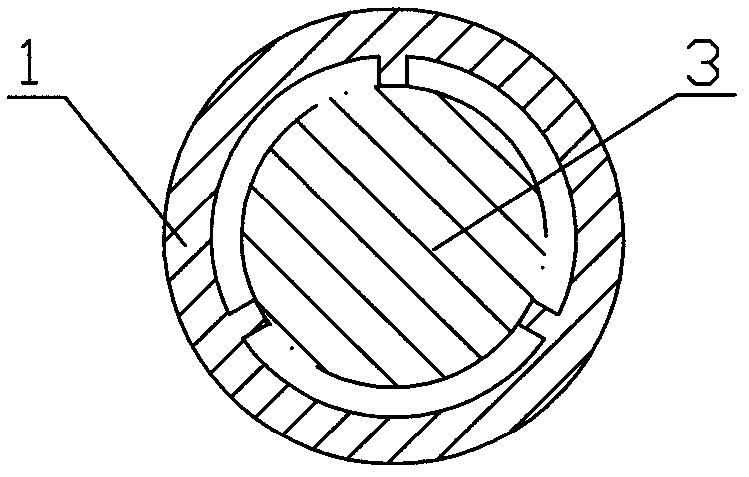

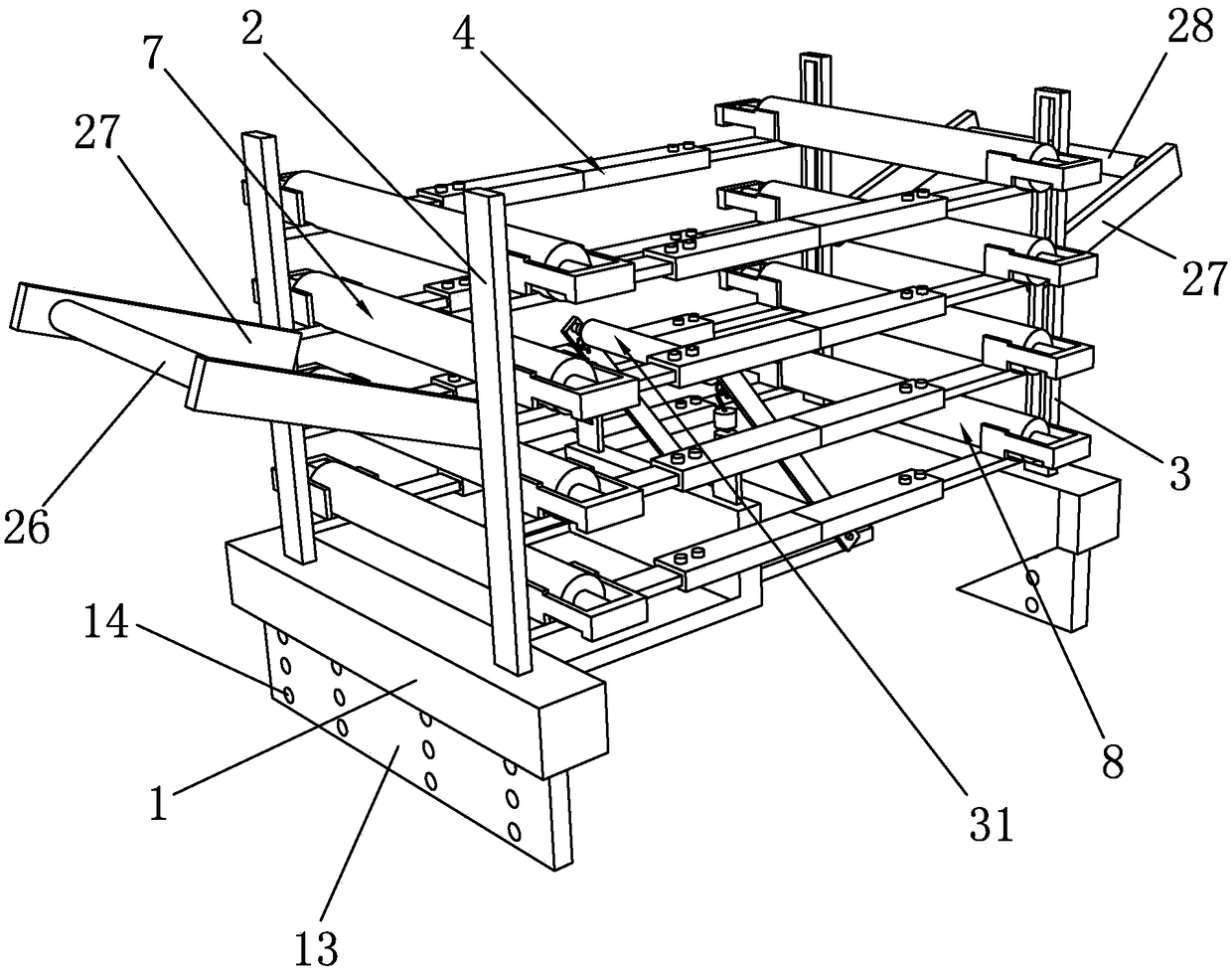

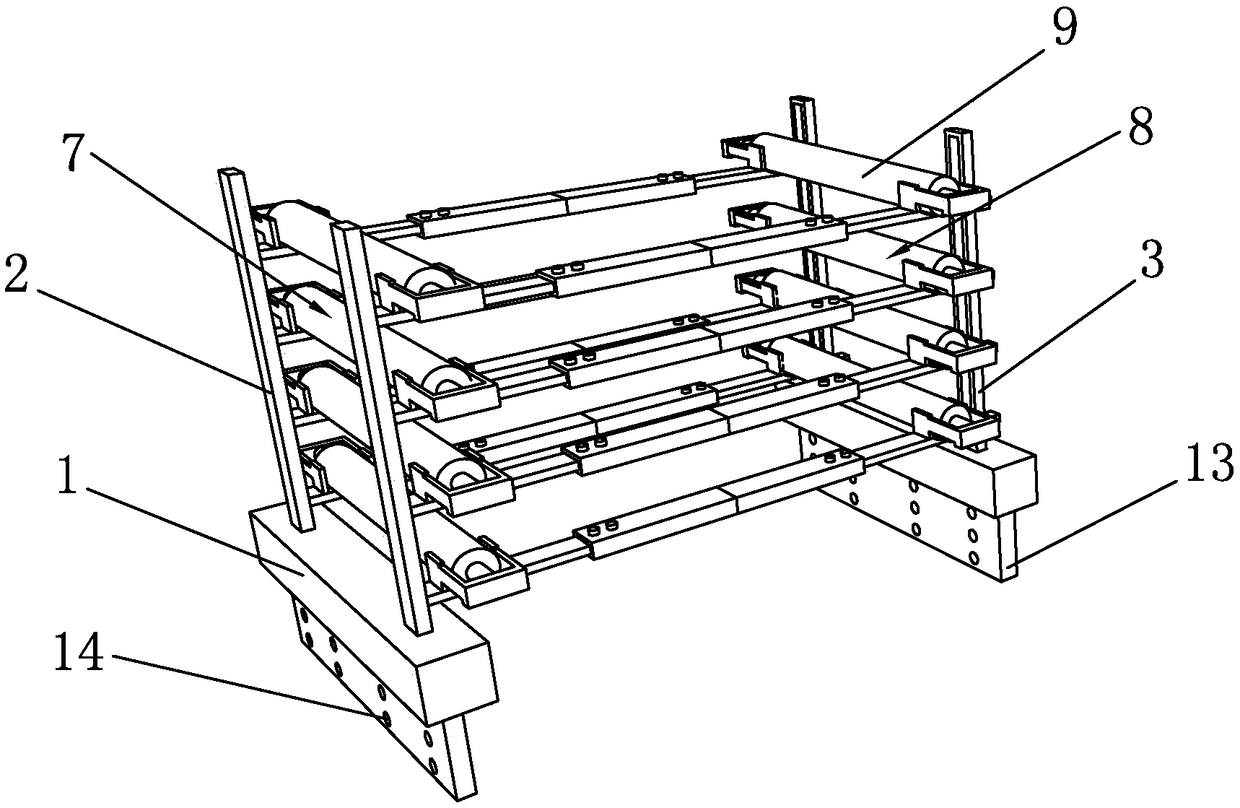

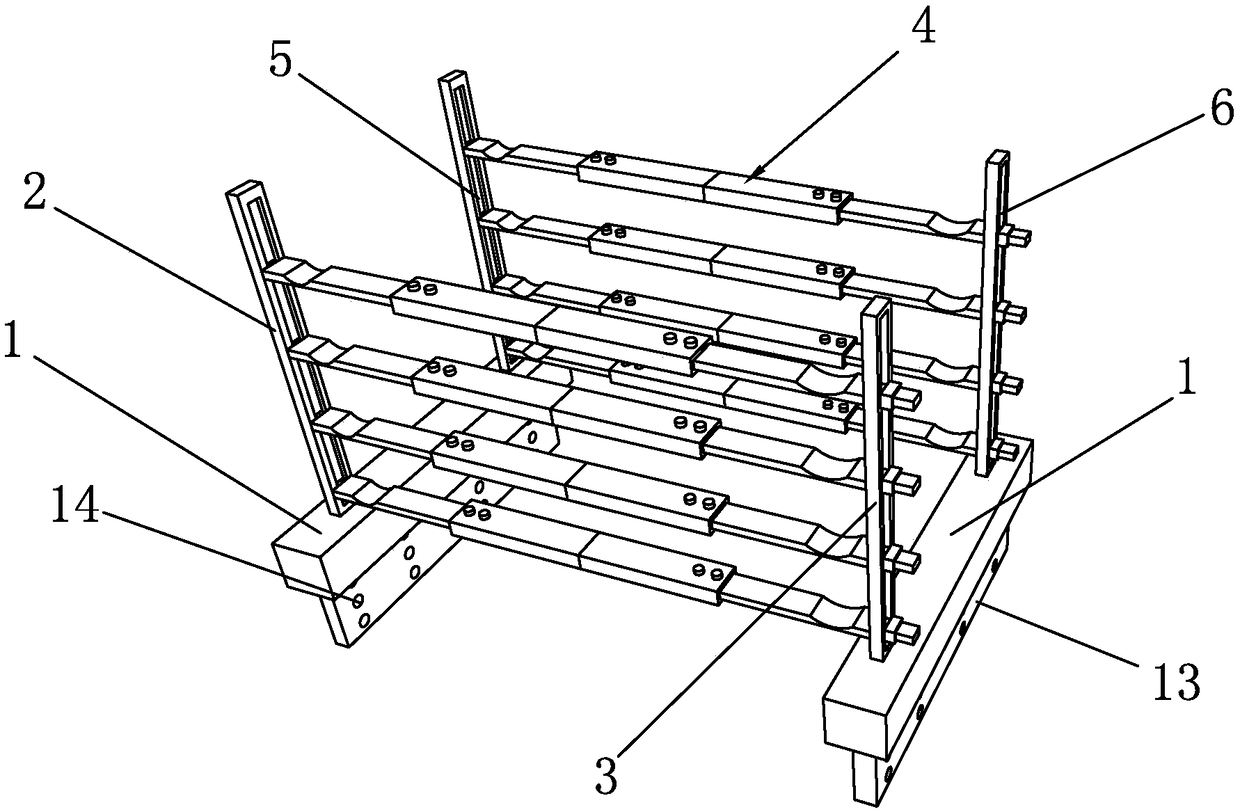

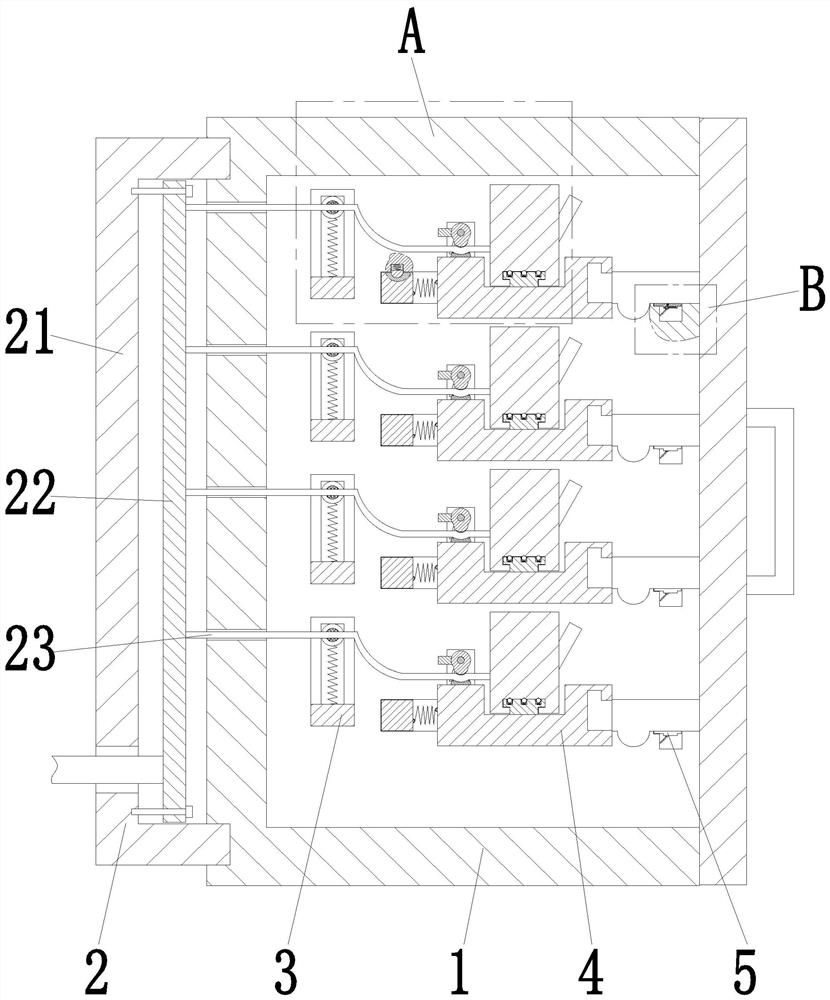

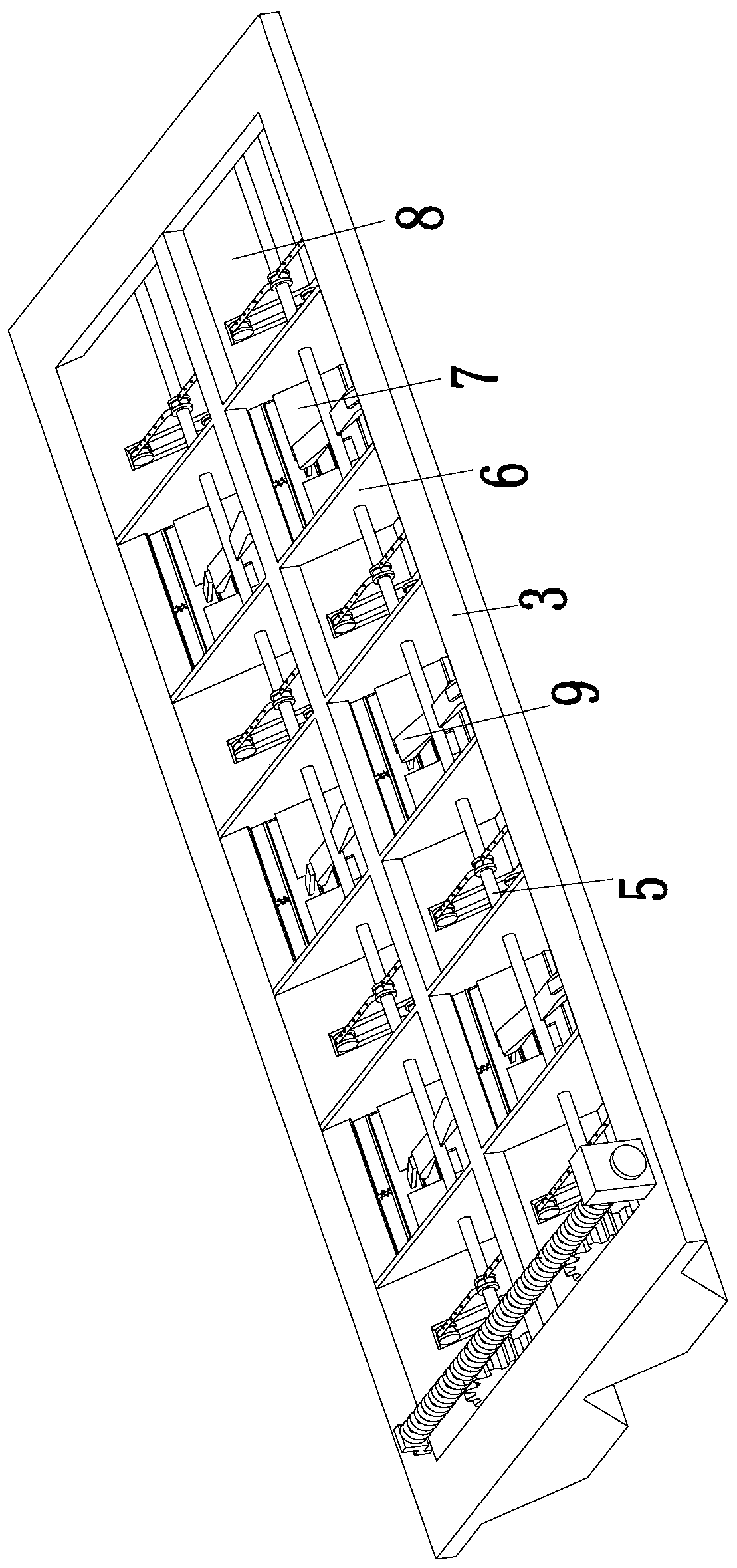

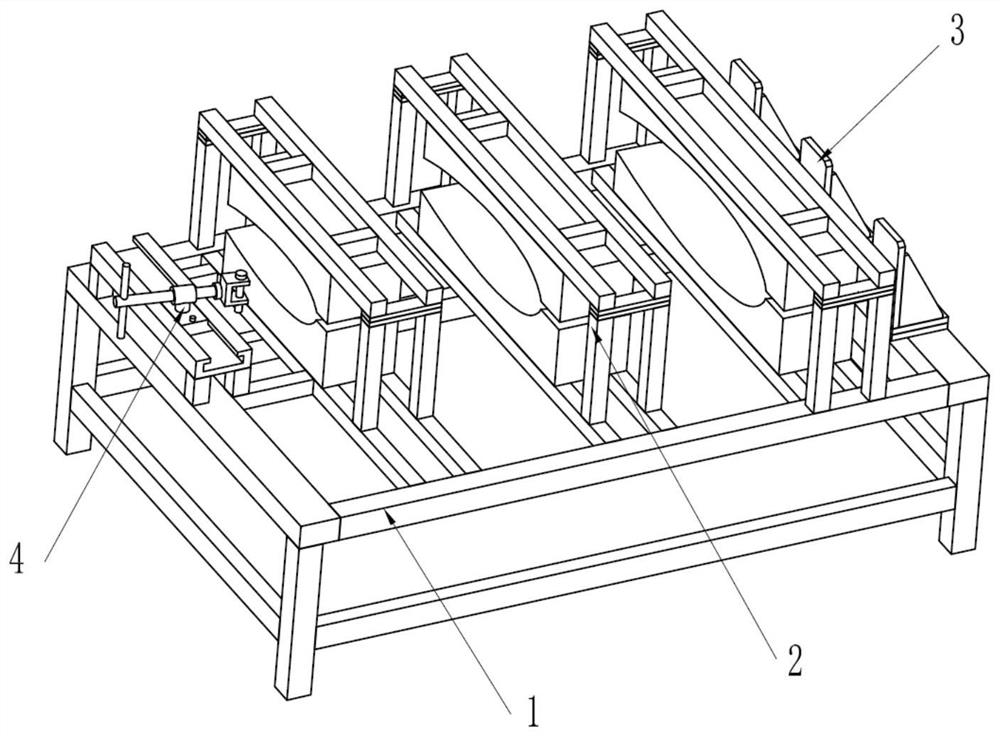

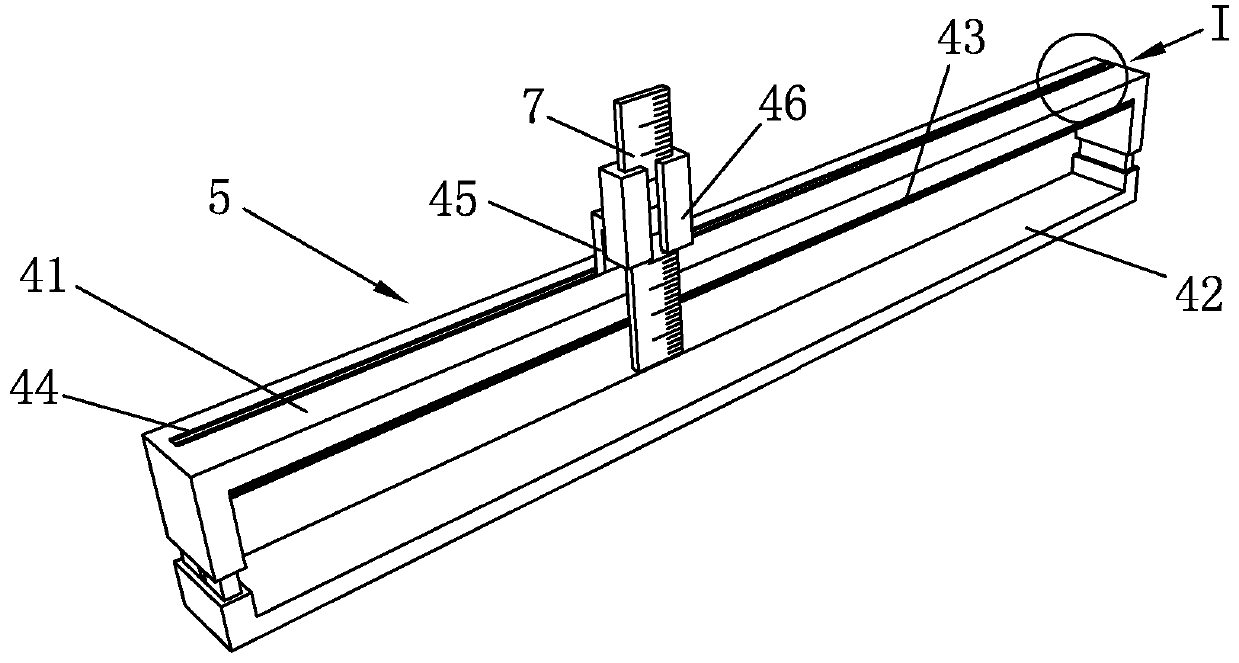

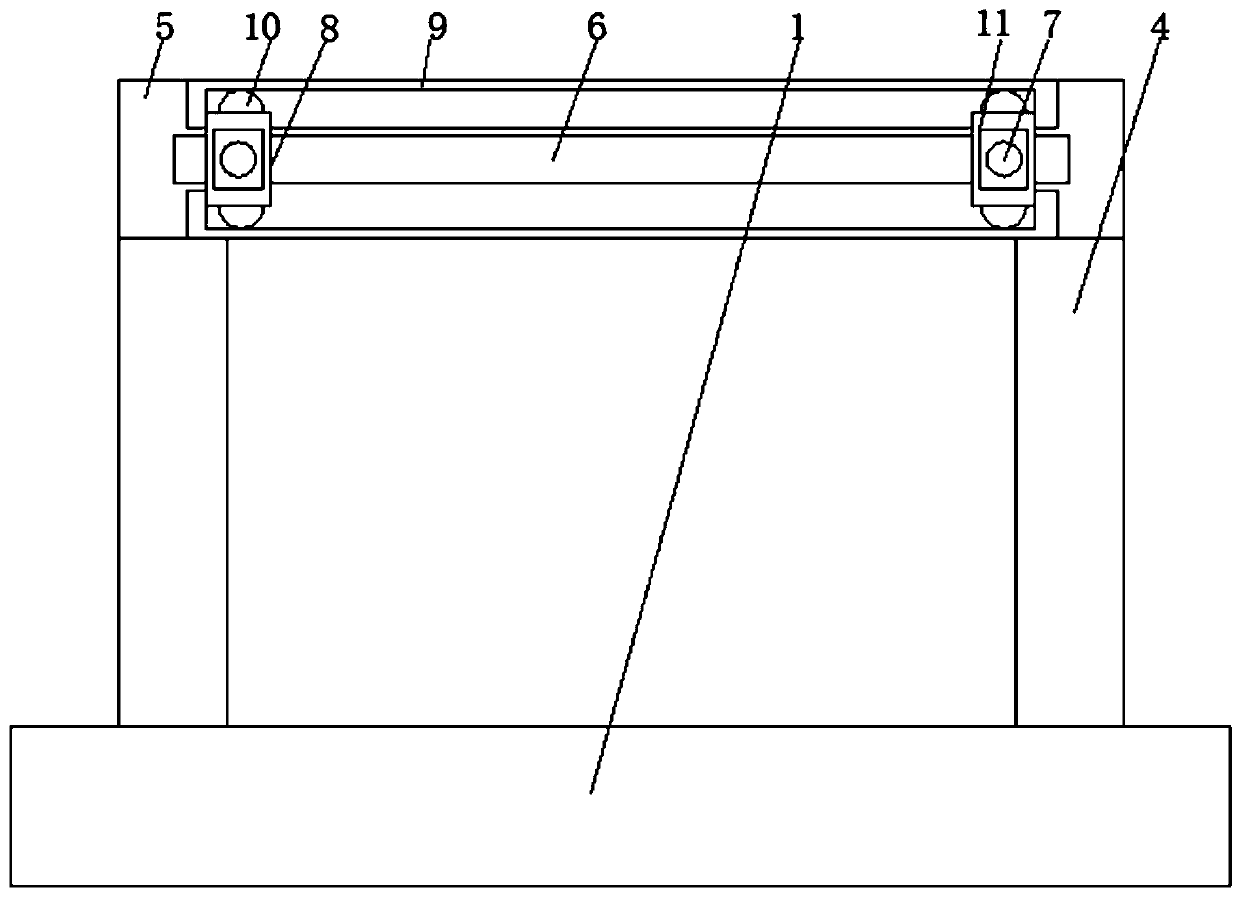

Coil vertical winding tensioning device and tensioning method

The invention relates to a coil vertical winding tensioning device and a tensioning method, and belongs to the technical field of transformer manufacture. According to the technical scheme, the coil vertical winding tensioning device comprises a lower chassis (1), an upper cover plate (2), upper necks (3), lower necks (4), rapid clamps (5), screws (7), bolts (8), left sliding blocks and right sliding blocks. The lower necks are formed in the left end and the right end above the lower chassis, the upper necks are formed in the left end and the right end below the upper cover plate, and the lower necks and the upper necks are mutually matched. The left sliding blocks are embedded in the lower chassis and the lower necks at the left end of the upper cover plate, the right sliding blocks are embedded in the lower chassis and the lower necks at the right end of the upper cover plate, the left sliding blocks and the right sliding blocks are same in structure and formed by front sliding blocks (9) and back sliding blocks (10) which are ranked together. The coil vertical winding tensioning device has the advantages that wires are arranged among the upper necks, the lower necks and the sliding blocks, threaded rods are screwed to ensure that the sliding blocks and the necks are stressed to clamp the wires and ensure that the wires are tensioned in the winding process of a coil, the structure is simple, and operation is convenient to conduct.

Owner:BAODING TIANWEI BAOBIAN ELECTRICAL

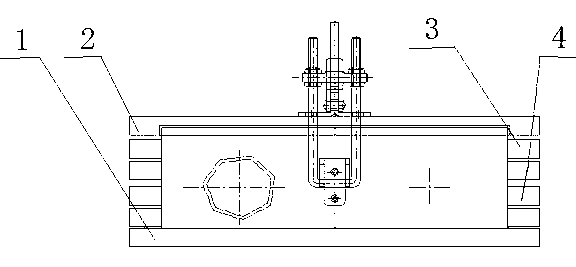

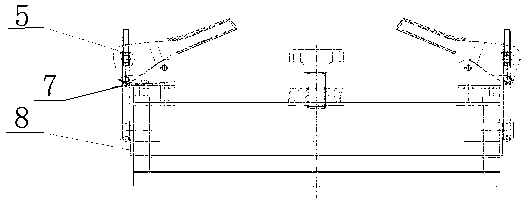

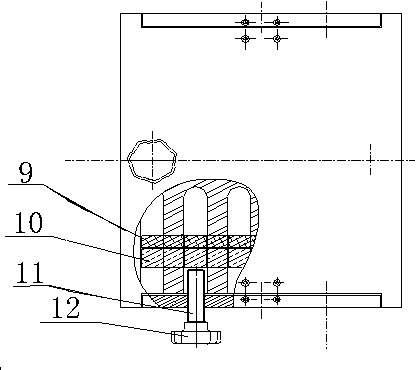

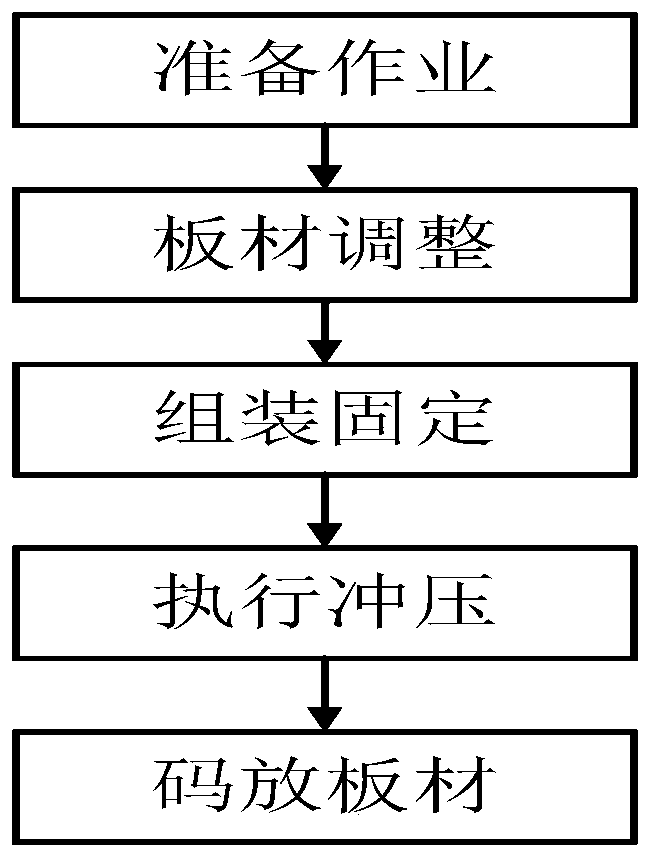

A stamping method for stamping large metal sheets

ActiveCN110180935BIncrease processing costAccuracy cannot be guaranteedShaping toolsMetal-working feeding devicesGas cylinderStructural engineering

Owner:中山市广恒合优科技发展有限公司

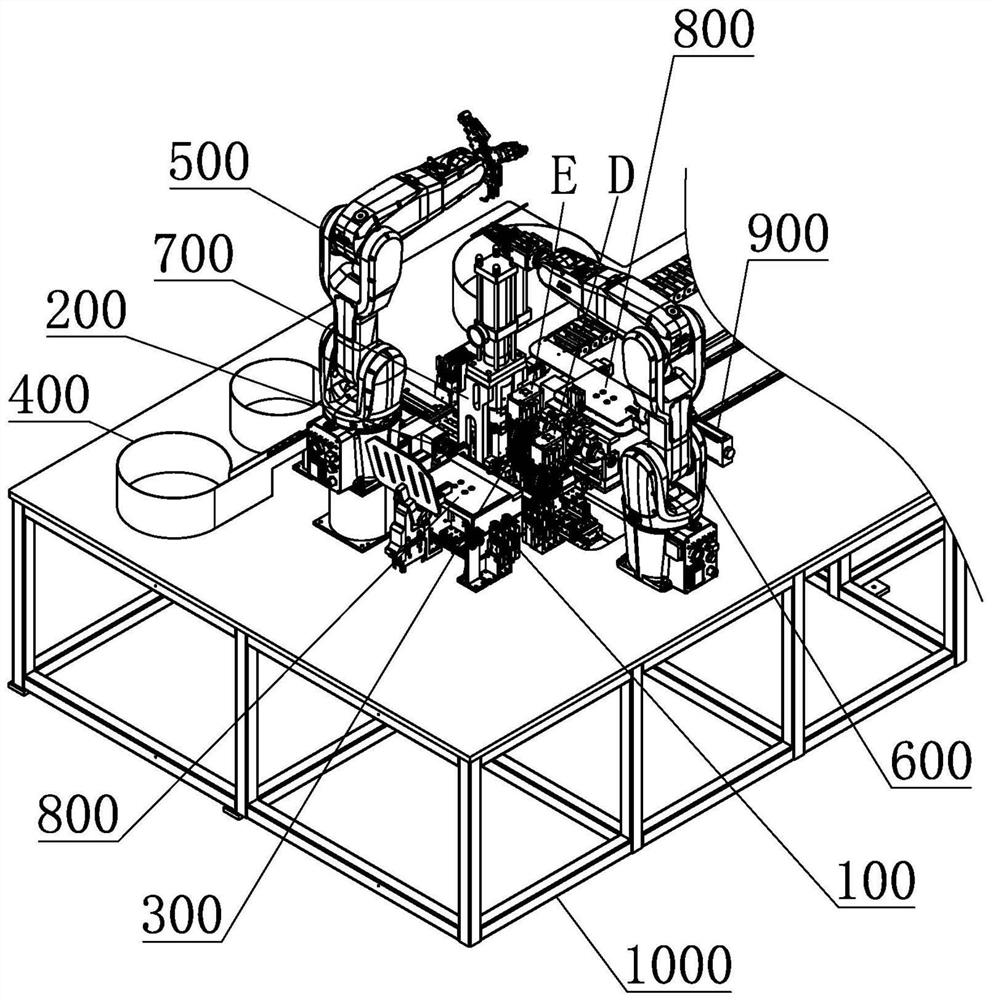

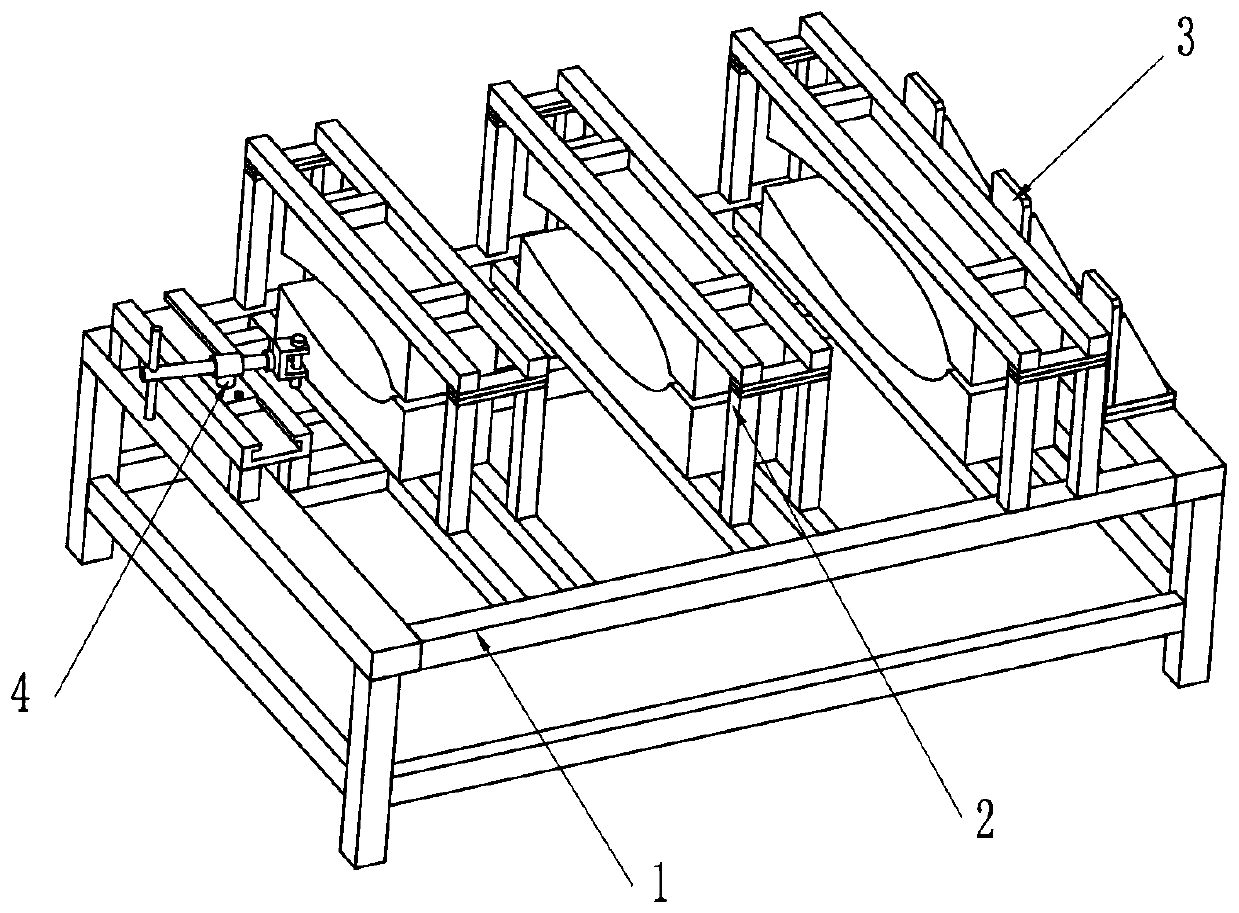

Intelligent dropper pre-configuration production line

PendingCN111774882ARealize preconfigured productionReduce labor intensityOther manufacturing equipments/toolsEngineeringManufacturing line

The invention discloses an intelligent dropper pre-configuration production line. The production line comprises a rack, a copper strand positioning and straightening unit, a robot braiding unit, press-fitting and wire-wrapping units, connecting wire clamp press-fitting units and a servo movement unit, wherein the copper strand positioning and straightening unit, the robot braiding unit, the press-fitting and wire-wrapping units, the connecting wire clamp press-fitting units and the servo movement unit are jointly arranged on the rack. The press-fitting and wire-wrapping units comprise press-fitting pipe press-fitting units and thimble positioning and wire-wrapping units, the copper strand positioning and straightening unit is used for smoothing out and cutting off a copper strand, the robot braiding unit is used for clamping the copper strand of the set length to penetrate through a press-fitting pipe and making the copper strand penetrate back to the press-fitting pipe and penetrate into a connecting wire clamp after the copper strand is wound around the thimble positioning and wire-wrapping units, the connecting wire clamp press-fitting units are used for press-fitting the connecting wire clamp, the servo movement unit is used for driving one set of the press-fitting and wire-wrapping unit to move for a set distance, and the press-fitting pipe press-fitting units are used forpress-fitting the press-fitting pipe. According to the intelligent dropper pre-configuration production line, through the cooperation of all the units, pre-configuration production of droppers can beachieved, thus the production efficiency can be improved, and the labor intensity of workers is effectively lowered.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP +1

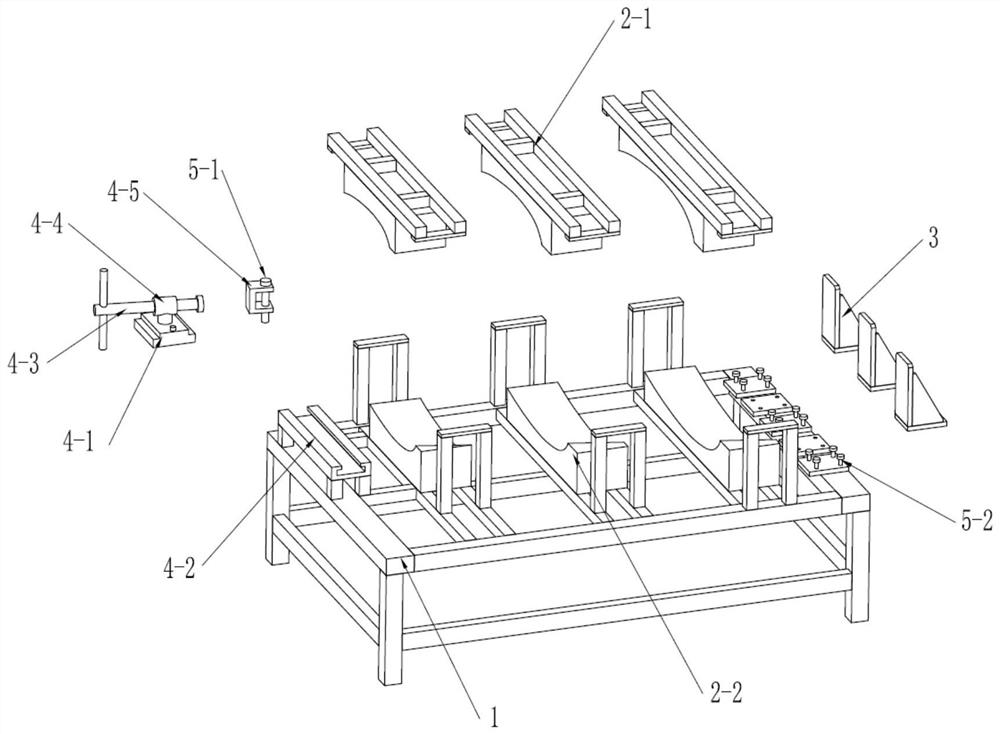

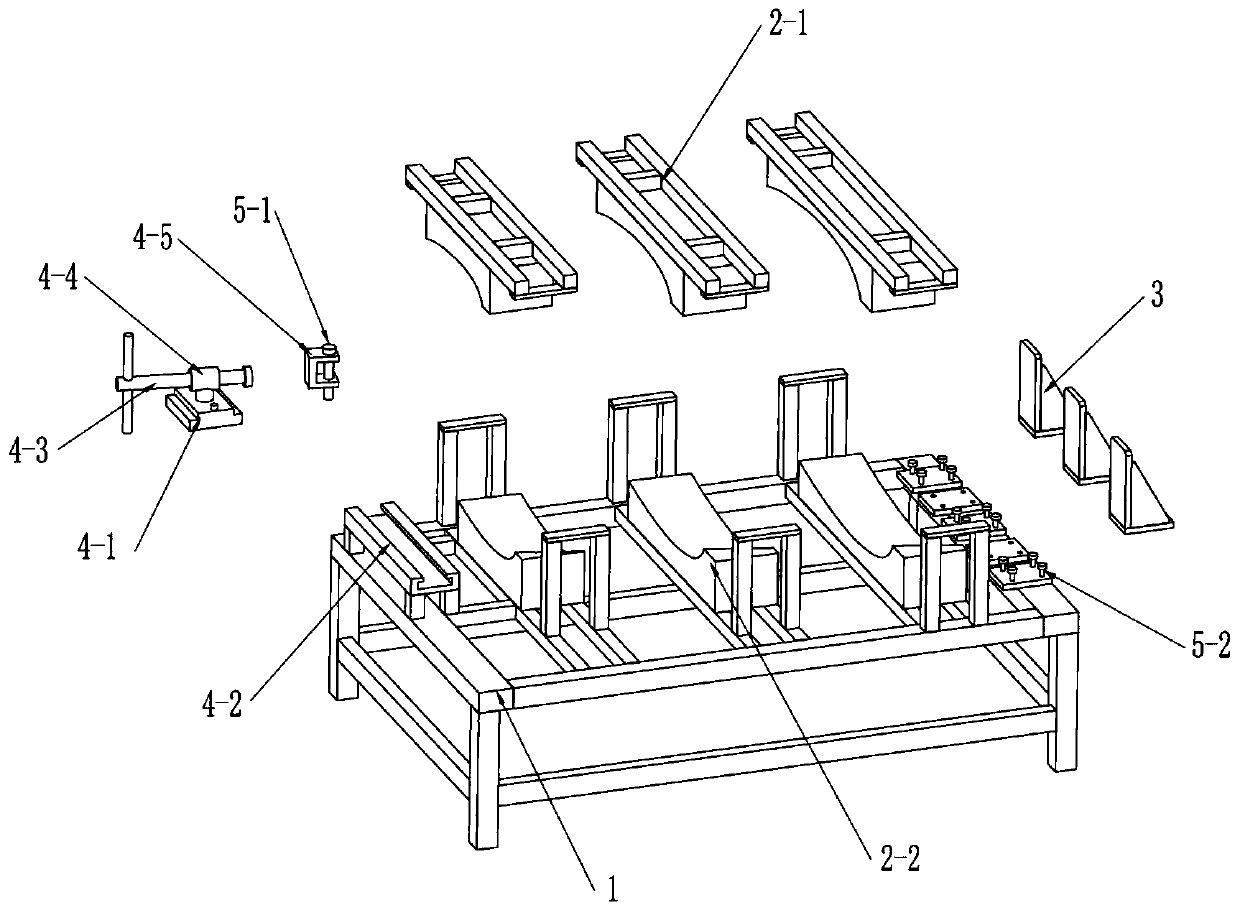

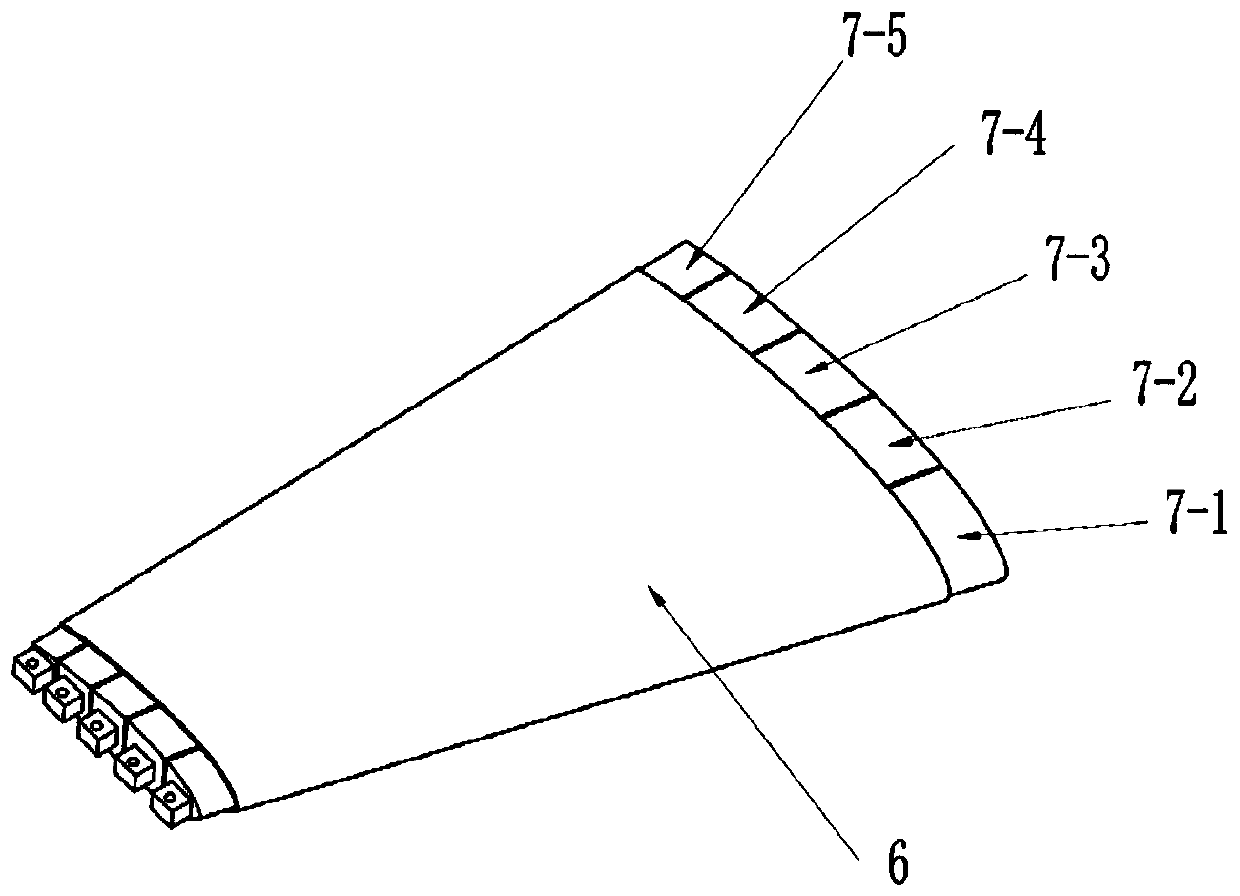

A demoulding tooling and demoulding method for multi-wall box-section structural composite parts

The invention belongs to the field of material preparation, and in particular relates to a demoulding tool and a demoulding method for a multi-wall box segment structural composite part. The demoulding tool is used for the demoulding of multiple core molds of multi-wall box-section structural composite parts, including a pressing plate assembly: including an upper pressing plate and a lower pressing plate, and the profile formed between the upper pressing plate and the lower pressing plate is consistent with The shape of the parts is consistent; the ejector mechanism: installed on the side of the small end of the mandrel, used to loosen the mandrel to be stripped; the stopper assembly: detachable, installed on the large side of the mandrel adjacent to the mandrel to be stripped The end is used to block the movement of the adjacent mandrel of the demolded mandrel. Place the multi-wall box segment structural composite part with the mandrel on the tooling, press the part tightly through the pressing plate assembly, install the stopper assembly at the big end of the mandrel, and use the ejector mechanism to push the mandrel in the part Eject in an orderly manner. The demoulding tool designed by the invention and the formulated demoulding method can realize the demoulding work of the multi-wall box segment structural composite parts conveniently, reliably and safely.

Owner:CETC WUHU DIAMOND AIRCRAFT MFG

Drying device and method of use thereof

ActiveCN108741152BMake sure it's tightReduce workloadFood treatmentEngineeringStructural engineering

The invention discloses a drying device, relates to the technical field of agriculture product harvesting, and is used for solving the problem that in the using course of a conventional drying machine, in order to thoroughly air-drying meal feeds, workers need to repeatedly overturn pressed meal, and sealing property between molecules of pressed meal granules can be destroyed, so that the pressedmeal cannot be compressed and compacted. The drying device comprises a mounting part, an air drying mechanism arranged on the mounting part and an adjusting mechanism for adjusting a wind outlet angleof the air drying mechanism, wherein the adjusting mechanism comprises a driving actuating rod, a driven actuating rod, a hinging piece for connecting the driving actuating rod with the driven actuating rod, a sliding sleeve, a left shaking plate, a right shaking plate, a shaking connecting rod, a first rotating shaft and a positioning bracket; and the left end of the shaking connecting rod is connected with the left shaking plate, and the right end of the shaking connecting rod is connected with the right shaking plate. According to the drying device provided by the invention, the wind outlet angle can be adjusted, after being subjected to squeezing and dewatering by a squeezing machine, the pressed meal keeps compressed and compacted, and the storing cycle is prolonged. The invention further discloses an application method of the drying device.

Owner:威海市大鹏环保设备有限公司

A cutting machine for the production of hardware accessories

ActiveCN109623022BIncrease cutting rateReduce the intensity of manual operationShearing machinesShearing machine accessoriesEngineeringMachine

The invention discloses a cutting machine for hardware fitting production. The cutting machine comprises a cutting table and a cutting head set; the cutting table is provided with a positioning module; the positioning module comprises a positioning clamping plate, a slide frame and a positioning staff; a placing table is arranged at the front end of the cutting table, and is hinged with the cutting table; a collecting box is arranged under the placing table; and the cutting head set comprises a vertical adjusting module, a transverse adjusting module, a longitudinal adjusting module and a cutting head. Through a positioning module, the precise positioning between the cutting head and a workpiece cutting position is realized, so that the cutting precision is effectively improved, and the cutting error rate is reduced; the positioning module also can be used for realizing pressing and positioning of workpieces, so that the cutting precision is further improved, and the workpieces are prevented from moving in the cutting process; meanwhile, the cut workpieces can be temporarily placed through the placing table; a rotating cylinder is matched to realize automatic collection of the workpieces; and the workpieces accumulated on the placing table are automatically put in the collecting box for collection, so that the manual operation intensity is effectively relieved.

Owner:南通旭之初新材料科技有限公司

Demolding tool and demolding method for multi-wall box section structure composite part

The invention belongs to the field of material preparation, and particularly relates to a demolding tool and demolding method for a multi-wall box section structure composite part. The demolding toolis used for demolding a plurality of core molds of the multi-wall box section structure composite part and comprises a pressing plate assembly, an ejection mechanism and a stop block assembly, the pressing plate assembly comprises an upper pressing plate and a lower pressing plate, a molded surface formed between the upper pressing plate and the lower pressing plate is consistent with the appearance of the part; the ejection mechanism is mounted on one sides of the small ends of the core molds and used for loosening the core molds to be removed; and the stop block assembly is detachable, is mounted at the large end of the adjacent core molds of the core molds to be removed, and is used for stopping the movement of the adjacent core molds of the core molds to be removed; and the demolding method for the multi-wall box section structure composite part comprises the following step that the multi-wall box section structure composite part with the core molds is placed on a tool, the part ispressed through the pressing plate assembly, the stop block assembly is installed at the large ends of the core molds, and the core molds in the part is ejected out in order through the ejection mechanism. By means of the demolding tool and the formulated demolding method for the multi-wall box section structure composite part, demolding work of the multi-wall box section structure composite partcan be conveniently, reliably and safely achieved.

Owner:CETC WUHU DIAMOND AIRCRAFT MFG

The method of preventing the cracks in the connection between the concrete structure and the back-filling wall

The invention discloses a method for preventing cracks at the connection part between a concrete structure and a post-built filling wall, which is characterized in that it comprises the following steps: construction of filling wall masonry construction-filling wall plastering construction-construction of anti-cracking cloth belt on the connection part, Among them, the construction process of pasting the anti-cracking cloth tape on the connection part is as follows: grinding and cleaning the surface of the substrate, stretching the thread on the surface of the substrate to determine the pasting range of the cloth tape, brushing the primer within the pasting range, and pasting the anti-cracking cloth tape And use the scraper to properly pressurize the cloth tape to fully moisten it. After the colloid is dried or cured, the surface of the anti-crack cloth tape is roughened or protected. The invention is beneficial in that: by improving and improving the current traditional masonry construction technology, it is ensured that the filling wall and the original concrete structure are tightly packed, and at the same time, the effective external reinforcement tape is used to further resist cracking or effectively cover, and the second road The defense lines work together, the whole process is simple, and it has an ideal anti-crack effect.

Owner:SHAANXI ACAD OF ARCHITECTONICS

An automatic polishing and chamfering machine for a table

ActiveCN106670933BAvoid slack strap situationsEnsure consistencyGrinding drivesBelt grinding machinesDistribution controlEngineering

The invention relates to an automatic polishing chamfering machine of a table board. The automatic polishing chamfering machine comprises a rack and a distribution control box. The rack is uniformly provided with polishing chamfering devices, each polishing chamfering device comprises an abrasive belt which is arranged on the rack and is upwards inclined from front to back, and a feeding mechanism matched with the table board and making the table board be fed in a front-rear horizontal manner is arranged in a gap between every two adjacent abrasive belts; and each feeding mechanism comprises a feeding device arranged on the rack and being capable of performing front-rear feeding, each feeding device is provided with a feeding clamper matched with the table board, and the feeding devices and the feeding clampers are connected to the distribution control box. According to the automatic polishing chamfering machine of the table board, the abrasive belts which are arranged in an inclined manner are adopted as the polishing chamfering devices in cooperation with the feeding mechanisms capable of making the table board be fed in a horizontal front-rear manner to achieve fixed-angle chamfering of the table board, chamfering efficiency is improved, the situation that abrasive belts are loose is avoided, and consistency of polishing chamfering is guaranteed.

Owner:广东顺德恒丽宝商用厨具有限公司

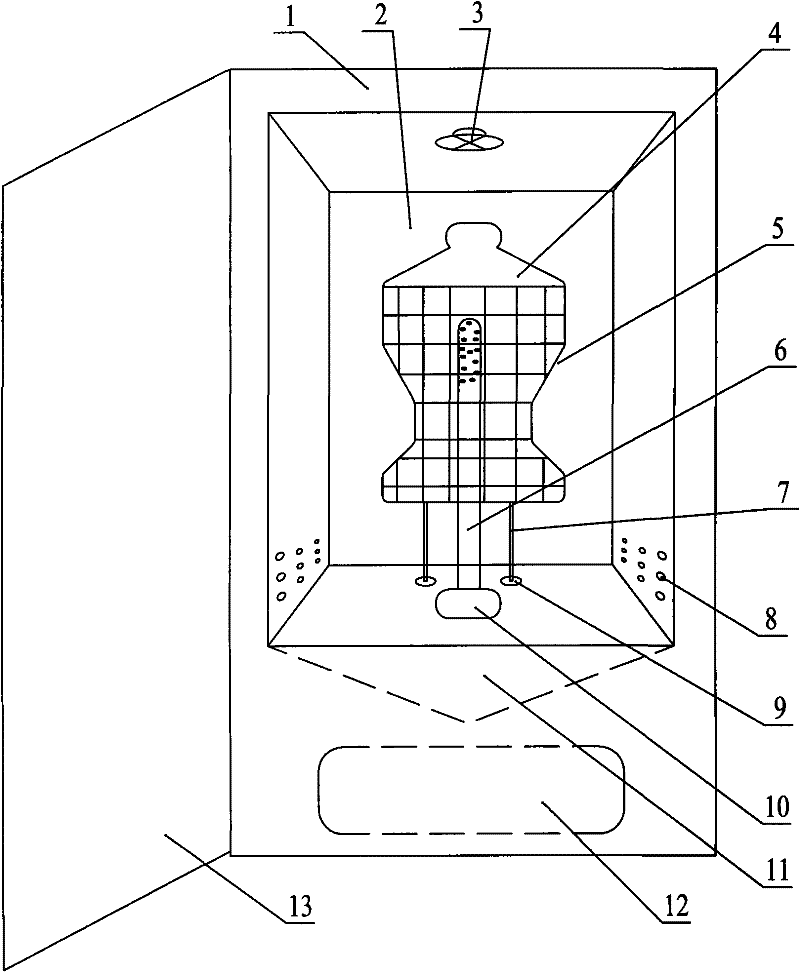

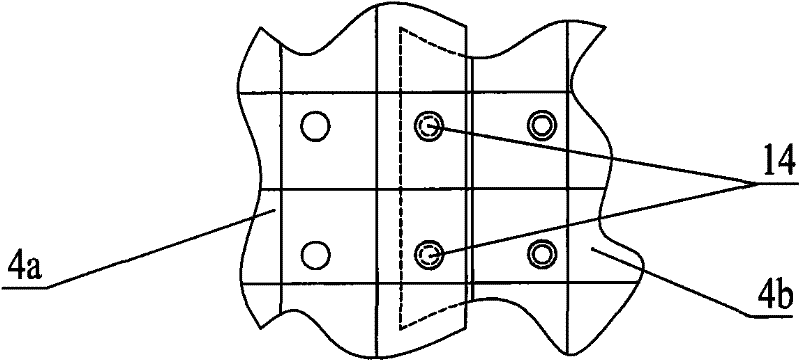

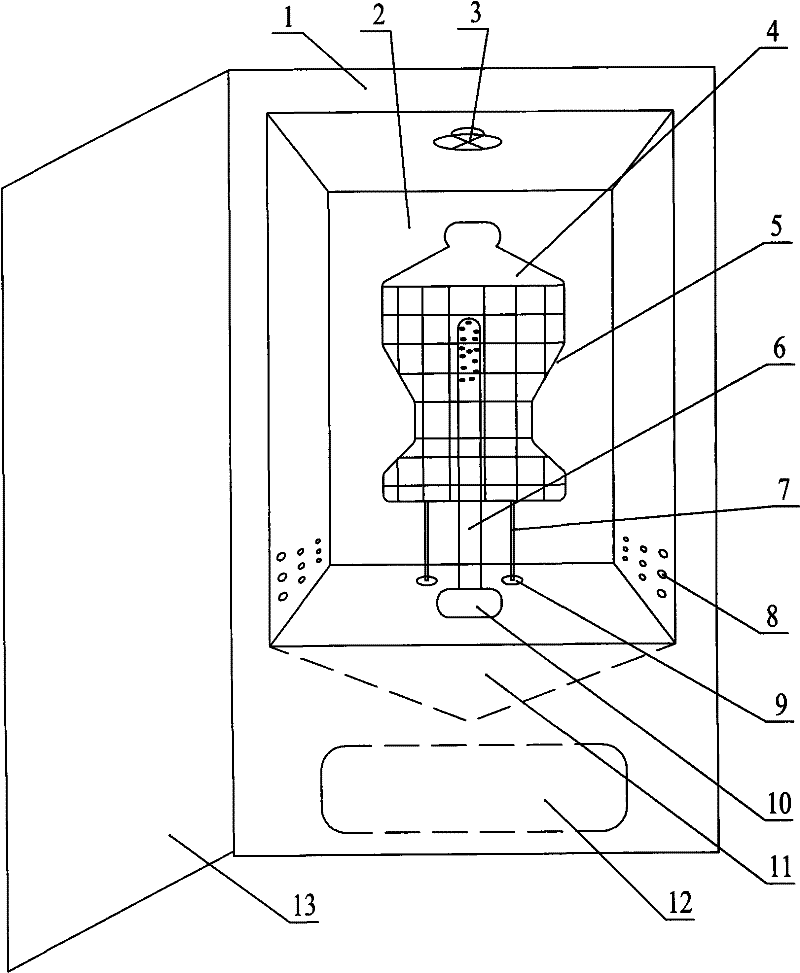

Steam washing machine with three-dimensional gridding clothing die

InactiveCN101838918BIngenious and reasonable structureImprove washabilityOther washing machinesTextiles and paperEngineeringAutomation

Owner:丁晔

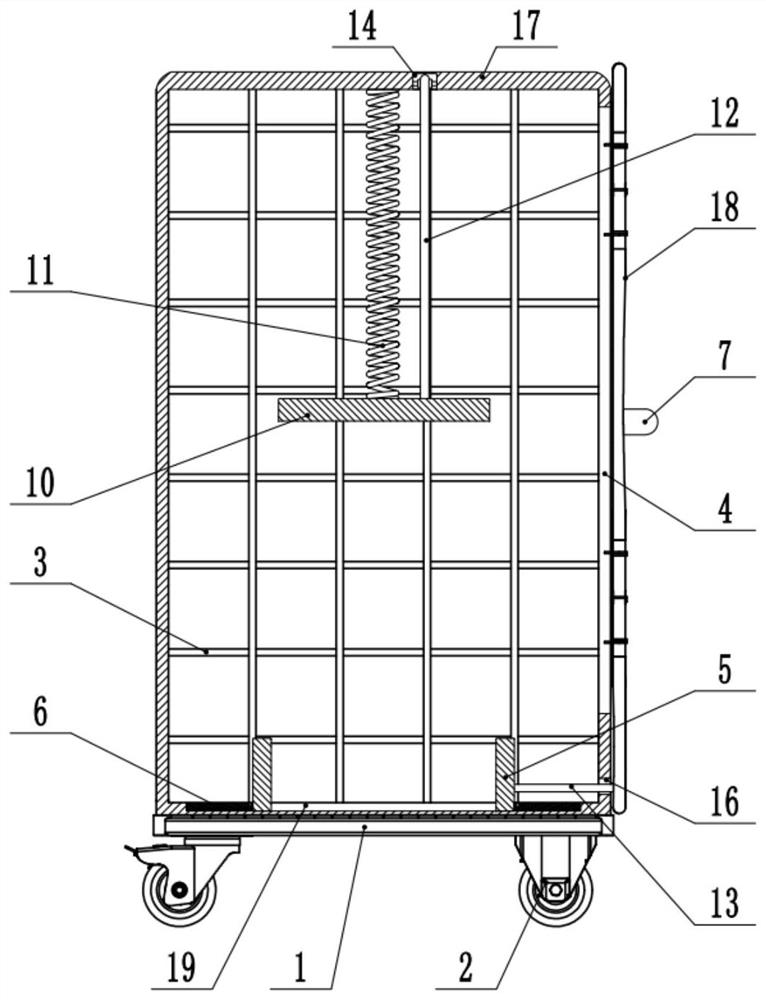

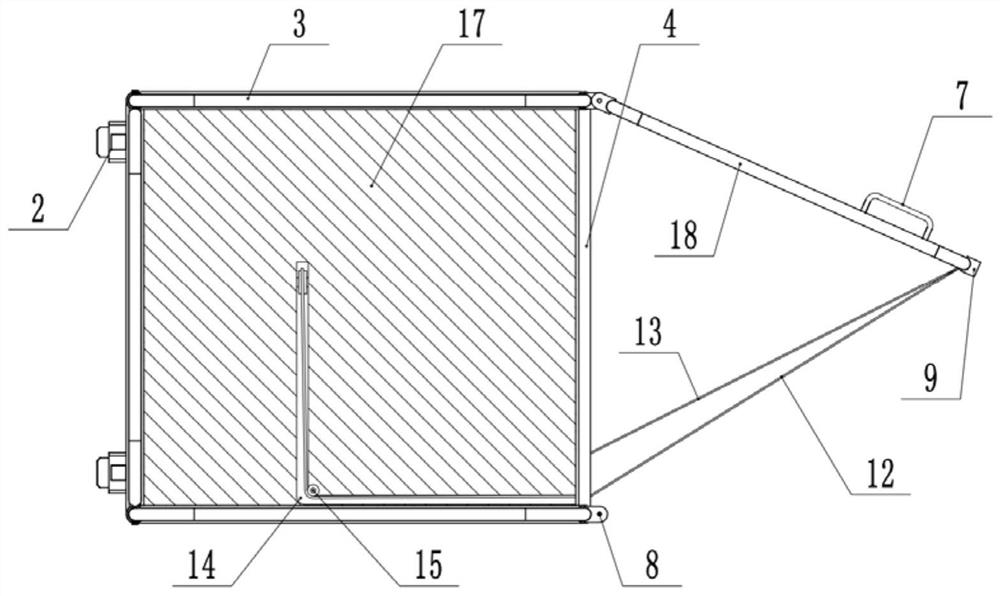

Logistics buffering and fixing device

InactiveCN113120044AImprove stabilityAvoid offsetHand carts with multiple axesHand cart accessoriesLogistics managementStructural engineering

The invention relates to the technical field of logistics transportation, and particularly discloses a logistics buffering and fixing device. The device comprises a bearing table, a fence is fixed to the top of the bearing table, a shielding plate is fixed to the top of the fence, an extrusion plate is arranged below the shielding plate and vertically connected to the side wall of the fence in a sliding mode, and a first compression spring is fixed between the extrusion plate and the shielding plate; and a feeding port is formed in one side of the fence and hinged to a door plate used for blocking the feeding port, the hinged free end of the door plate is fixedly connected with a first rope, and the end, away from the door plate, of the first rope is fixedly connected to the top of the extrusion plate. The invention aims to provide the logistics buffering and fixing device so as to solve the technical problem that express goods are prone to bumping and damage.

Owner:CHONGQING VOCATIONAL INST OF ENG

Film applicator capable of automatically rewinding at time of belt replacement and starting

The invention provides a film applicator capable of automatically rewinding at the time of belt replacement and starting. The film applicator comprises an applicator body for mounting a filling body, the applicator body comprises a front housing, a rear housing, an application head, a first transmission shaft, a second transmission shaft and the like, the front housing and the rear housing move relative to each other by means of a side guide groove and a carrier plate, and the application head, the first transmission shaft, the second transmission shaft and the like can slide out along with the carrier plate; and a rewinding linkage mechanism consisting of a rewinding touch unit and a rewinding linkage unit is arranged. When a user performs starting for replacement, an unwound thin film belt can be automatically linked and rewound, the thin film belt can be kept in a tightened state, and the convenience during replacement operation is improved.

Owner:富联(厦门)办公用品有限公司

A method for eliminating short process to produce 1.175mm high-strength steel coiled oval coil

ActiveCN112044956BAvoid the problem of increased deflectionMitigates the risk of strip breakage due to strip edge thinningTension/compression control deviceMetal rolling arrangementsEngineeringStrip steel

The invention discloses a method for producing 1.175mm high-strength steel coiling elliptical coils by eliminating short process flow. The method includes controlling the strip steel unit tension, reducing the pinch roller pressure, adjusting the coil diameter tension, and adjusting the tension during the strip steel coiling process. distribution, and clockwise rotation after the coil stays after coiling. The invention can eliminate the short-flow production of 1.175mm high-strength steel coiled oval coils.

Owner:武汉钢铁有限公司

Fixing system of roller sports shoes

ActiveCN103331021AMake sure to pivotEasy to disengageFootwearSkate-boardsClassical mechanicsStructural engineering

The invention relates to roller sports shoes (1), comprising a base (2), a supporting plate (4) and a wearing component (5). The wearing component is provided with an upper (10) pivoted backward with respect to the supporting plate. At least one elongated member (29) is disposed between the supporting plate and a tensioning system (23) disposed on the upper. The tensioning system is assembled in a manner that the elongated member is tensioned at a first position to lock the backward pivoting of the upper, and the elongated member is loosened at a second position to allow the backward pivoting of the upper. A coating device enabling a front upper to cover the back of the foot is disposed between the upper and the front upper.

Owner:DECATHLON SA

Vehicle wheel hub end face milling device

PendingCN110587396AEasy to operateImprove polishing efficiencyEdge grinding machinesGrinding carriagesEngineeringDrive motor

The invention relates to a vehicle wheel hub end face milling device. The device comprises a base, a grinding device, a longitudinal adjusting supporting device, a transverse adjusting supporting device and a clamping device; the upper surface of a first region of the base is internally provided with two convex grooves; the grinding device comprises two grinding assemblies, and each grinding assembly comprises a grinding head, a drive motor and a motor base; the longitudinal adjusting supporting device is used for adjusting the displacement of the grinding device longitudinally and comprises two longitudinal adjusting supporting assemblies; the transverse adjusting supporting device is used for adjusting the displacement of the grinding device transversely and is connected to the two longitudinal adjusting supporting assemblies and the two motor bases are movably mounted on the transverse adjusting supporting device, so that the grinding device moves through the transverse adjusting supporting device relative to the base in the transverse direction; and the clamping device comprises a fixed seat, a driving device and a clamping assembly, and the clamping assembly comprises a longitudinal constraint unit and a transverse constraint unit. In use, the grinding operation is convenient, the grinding quality is good, and wheel hubs are clamped firmly.

Owner:CITIC DICASTAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com