Tension regulating device for textile production

A tension adjustment device and textile technology, which is applied in the direction of transportation and packaging, winding strips, and conveying filamentous materials, can solve problems such as breakage, affecting the use value of fabrics or yarns, and wrinkles of fabrics or yarns. Ease of use, improved structural stability, and reduced incidence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

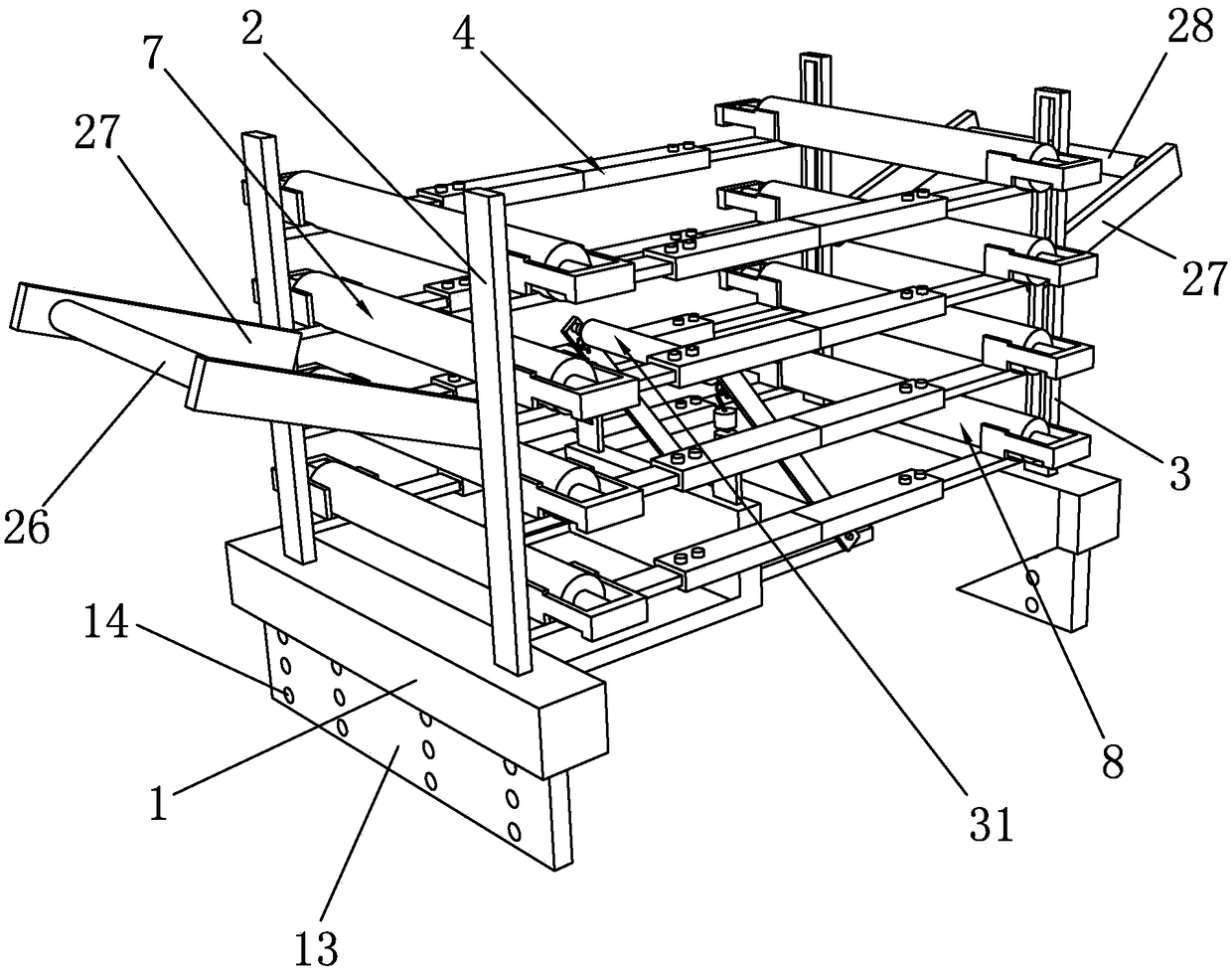

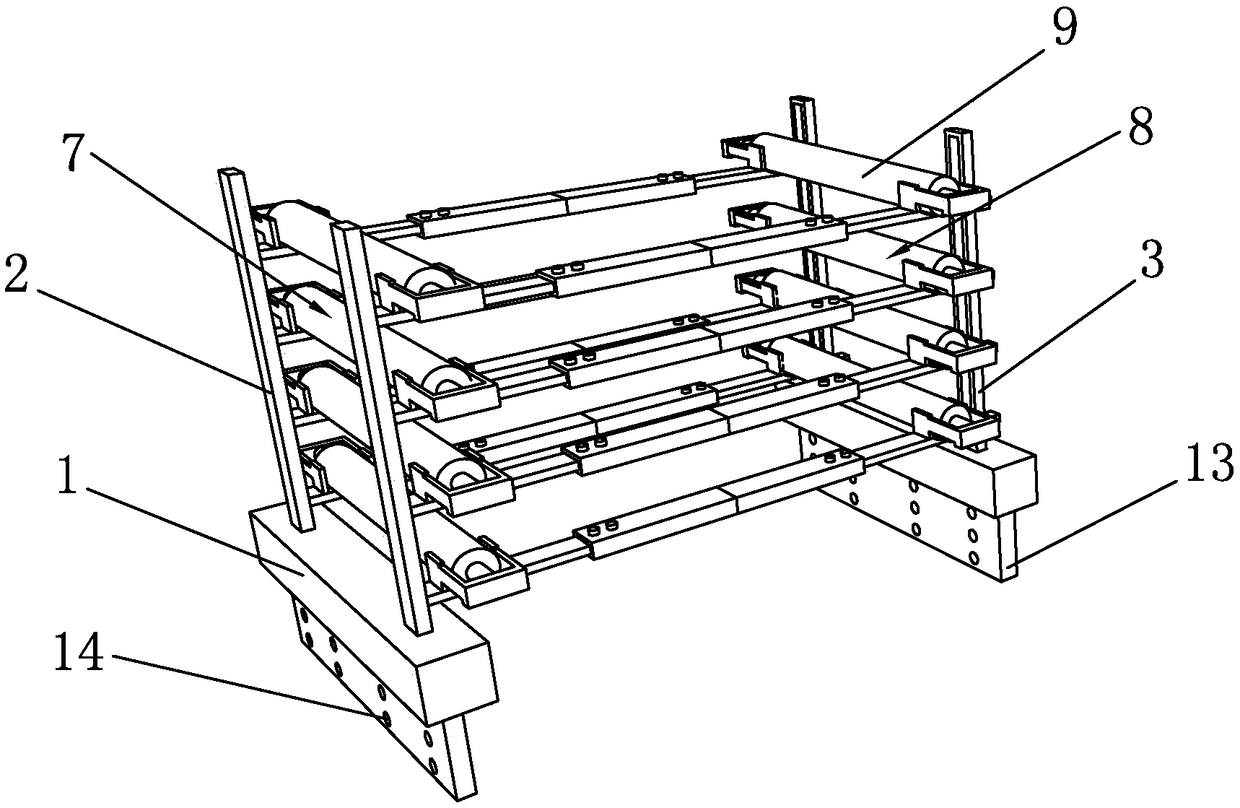

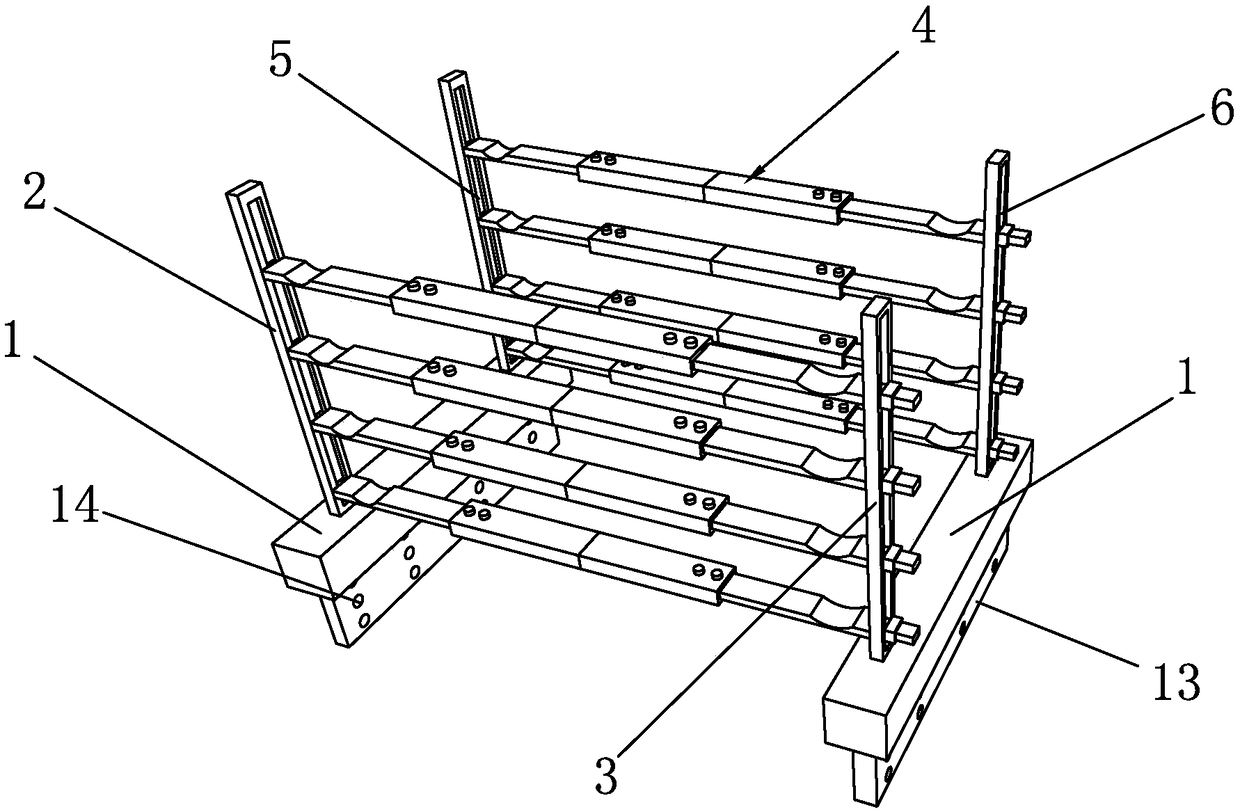

[0030] like Figure 1 to Figure 9 As shown, it is a tension adjustment device for textile production according to the present invention, which includes an adjustment frame, 9 sets of adjustment rollers and a tenter assembly 31. The left side of the adjustment frame is provided with a lead roller 26, and the lead roller 26 is connected with the connecting rod 27 and The first support column 2 is connected, and the right side of the adjustment frame is provided with a discharge roller 28. The discharge roller 28 is connected with the second support column 3 through a connecting rod 27. The design of the lead roller 26 can guide the cloth or yarn to enter quickly. In the pressure regulating device, the tension of the cloth or yarn is adjusted, and the design of the discharge roller 28 can guide the cloth or yarn to be delivered to the next device for processing.

[0031] The adjustment frame includes two fixed blocks 1, a first support column 2 and a second support column 3, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com