Demolding tool and demolding method for multi-wall box section structure composite part

A box section and tooling technology, which is applied in the demoulding tooling field of multi-wall box section structural composite parts, can solve the problems of high adhesion between the part and the mandrel, large contact area, difficult demoulding, etc., and achieve simple structure , safe operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings.

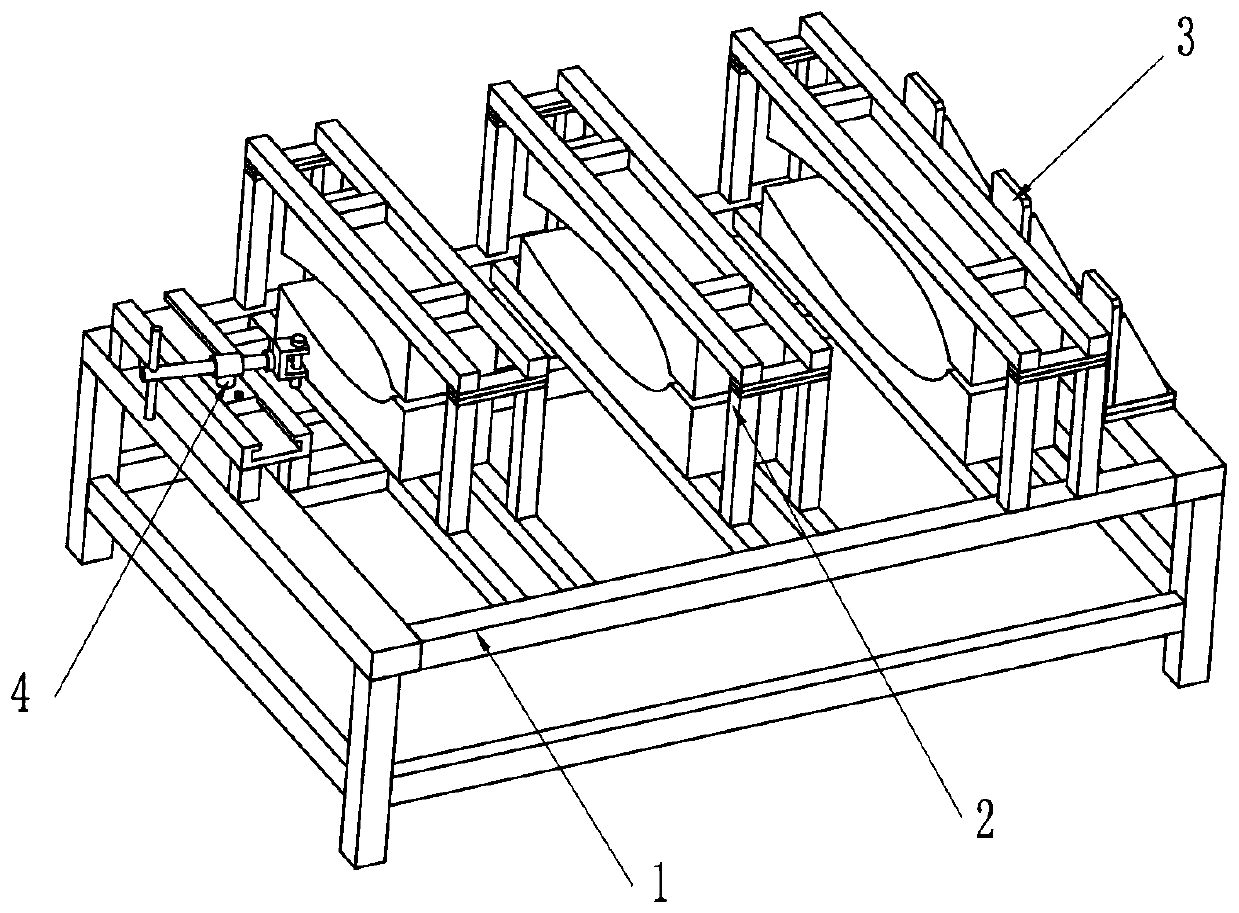

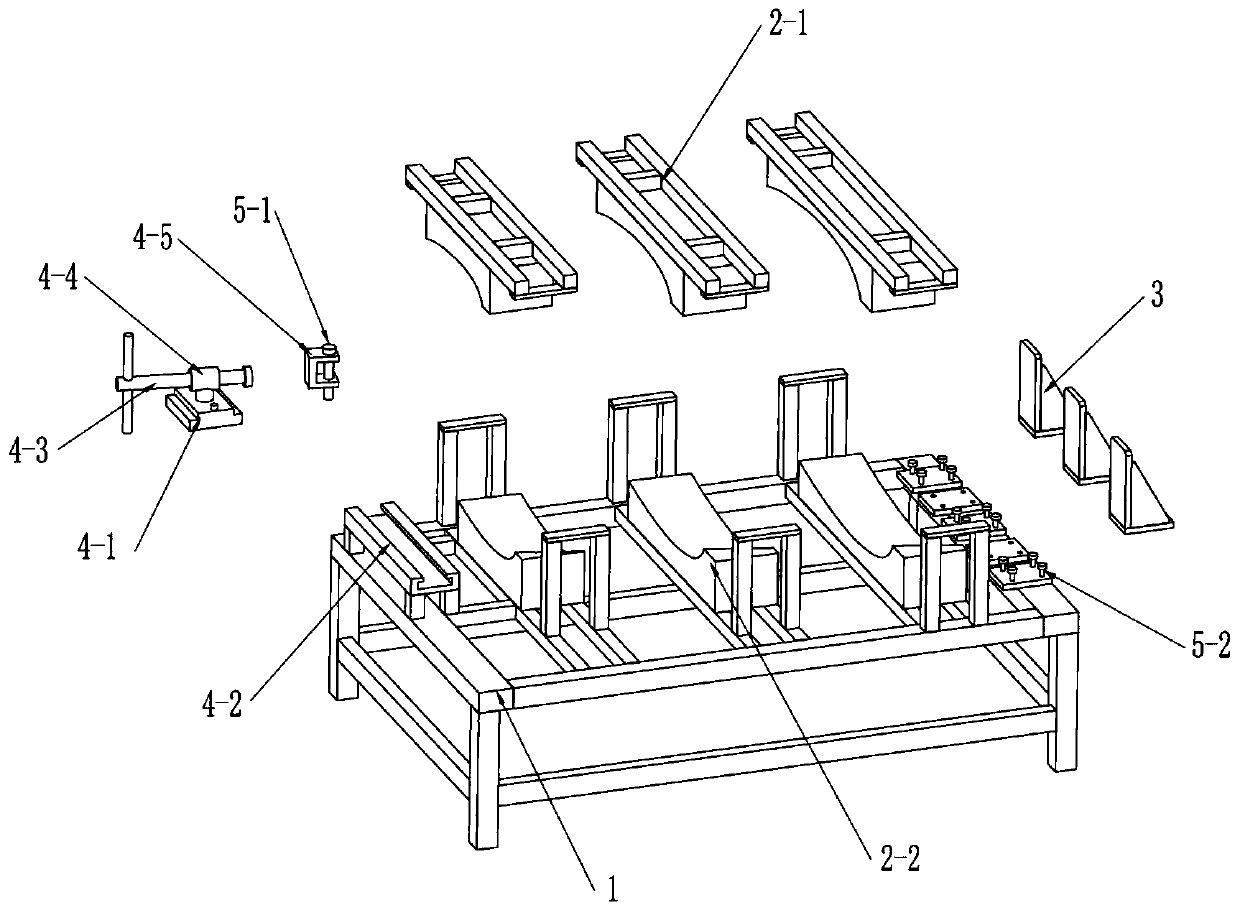

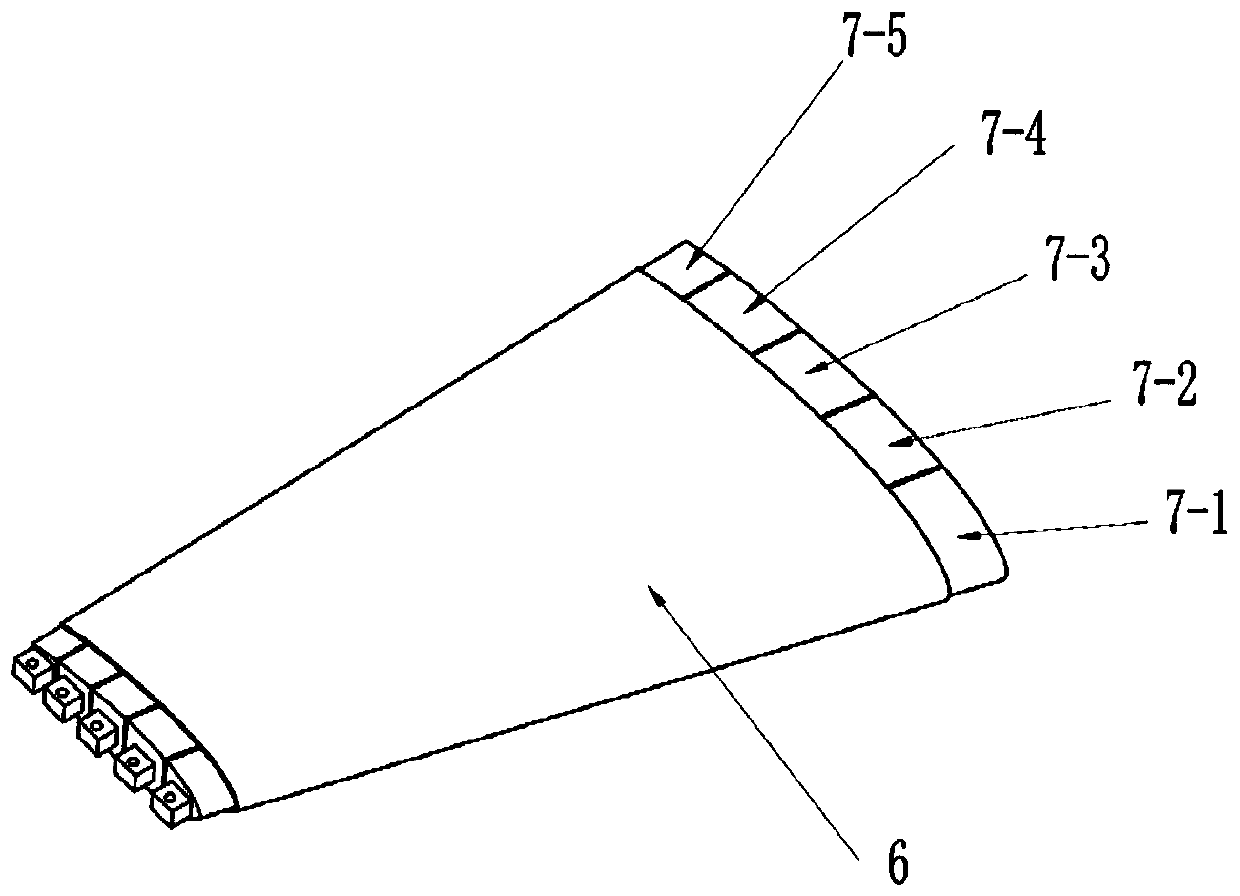

[0038] Such as Figure 1-4 As shown, a demoulding tooling for multi-wall box-section structural composite parts. The tooling includes five parts: a bottom frame 1, a pressure plate assembly 2, a stopper assembly 3, an ejection mechanism 4, and a positioning connector.

[0039] The pressing plate assembly is composed of an upper pressing plate 2-1, a lower pressing plate 2-2, and a silica gel sheet. The upper and lower pressing plates are made of wood, and its profile is consistent with the shape of the workpiece.

[0040] The ejector mechanism 4 is composed of T-shaped slot 4-2, T-shaped block 4-1, screw rod 4-3, nut 4-4, and C-shaped top block 4-5. The T-shaped block can slide along the T-shaped slot, and the nut is connected It can be rotated on the T-shaped block, and the position and direction of the screw rod can be adjusted by moving the T-shaped block...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com