Coil vertical winding tensioning device and tensioning method

A tensioning device and vertical winding technology, which is applied in the field of transformer manufacturing, can solve the problems of tension, failure to use wires, and easy confusion of wires, etc., and achieve the effect of easy operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

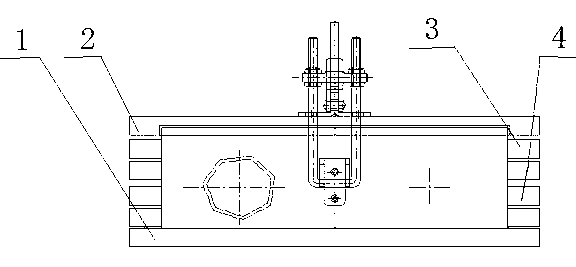

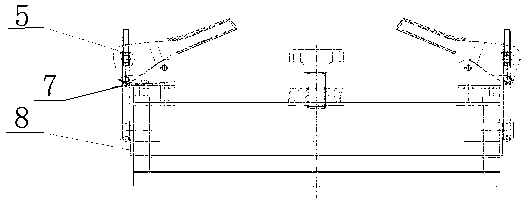

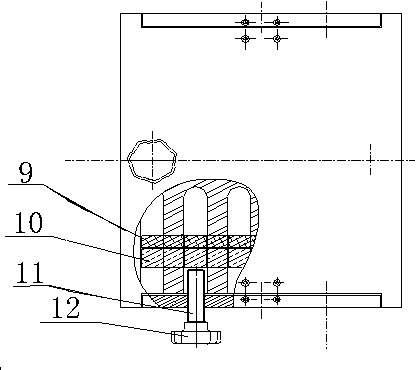

[0028] After the lower card slot and the lower chassis are installed, the left slider and the right slider are respectively inserted into the lower card slots at both ends, and a plurality of wires arranged in a row are placed in the middle of the left slider and the right slider, and pass through the lower chassis. The baffles on both sides screw in the screw to make it withstand the rear slider, and slowly tighten the screw to force the front slider to clamp the wire in the radial direction;

[0029] After aligning the upper card slot and the upper cover plate, put the upper card slot on the protruding left and right sliders, and clamp them with quick clamps. The upper part of the quick clamps is fixed with screws On the upper cover, the lower part is fixed on the lower chassis with bolts; through the star-shaped handle installed on the upper cover, the inner screw pushes against the upper clamping groove, and the upper clamping groove is stressed to clamp the wire in the ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com