A cutting machine for the production of hardware accessories

A technology for cutting machines and accessories, applied in the direction of shearing devices, metal processing equipment, manufacturing tools, etc., can solve the problems of easy deviation, affecting cutting effect, increasing product defective rate, etc., achieve simple structure, improve structural strength and Stability, easy to use and simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

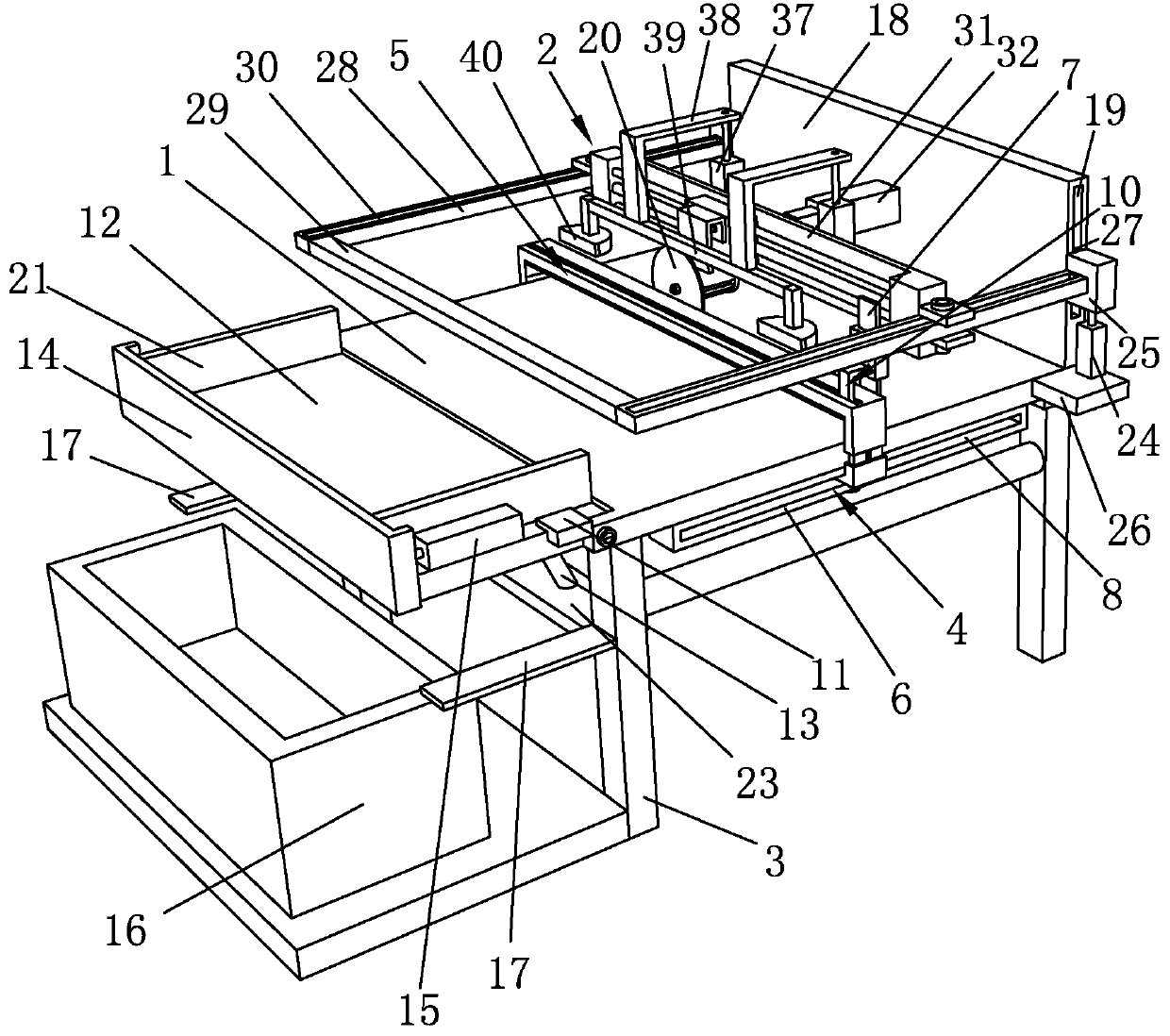

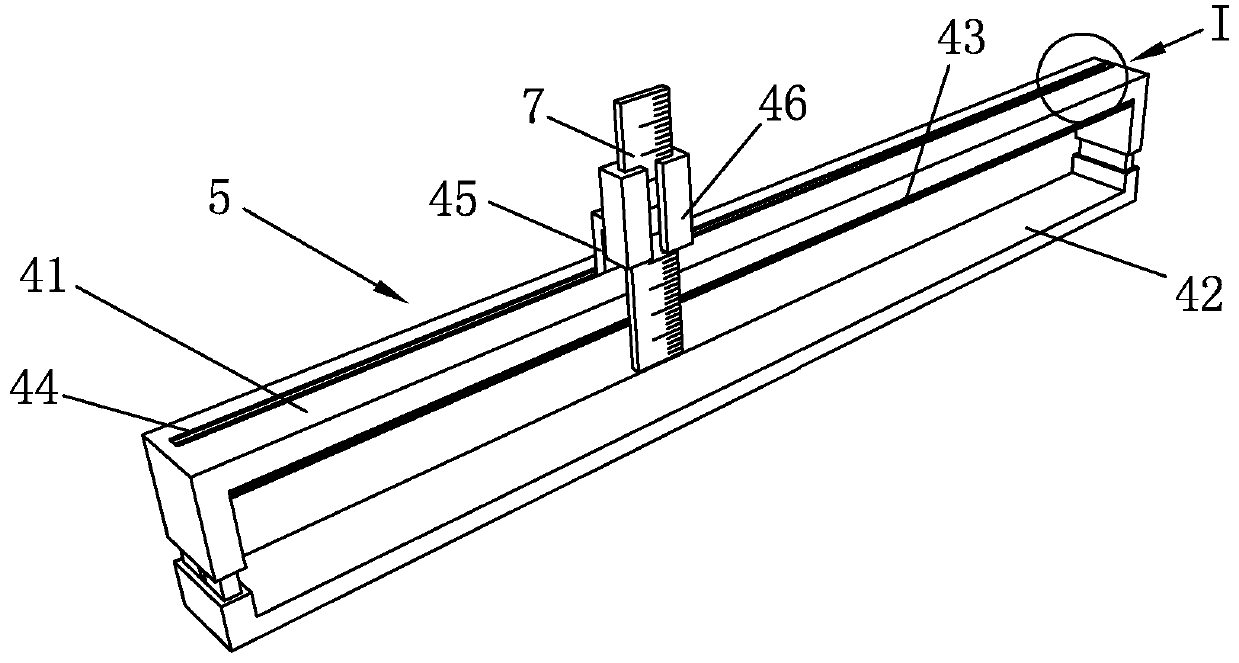

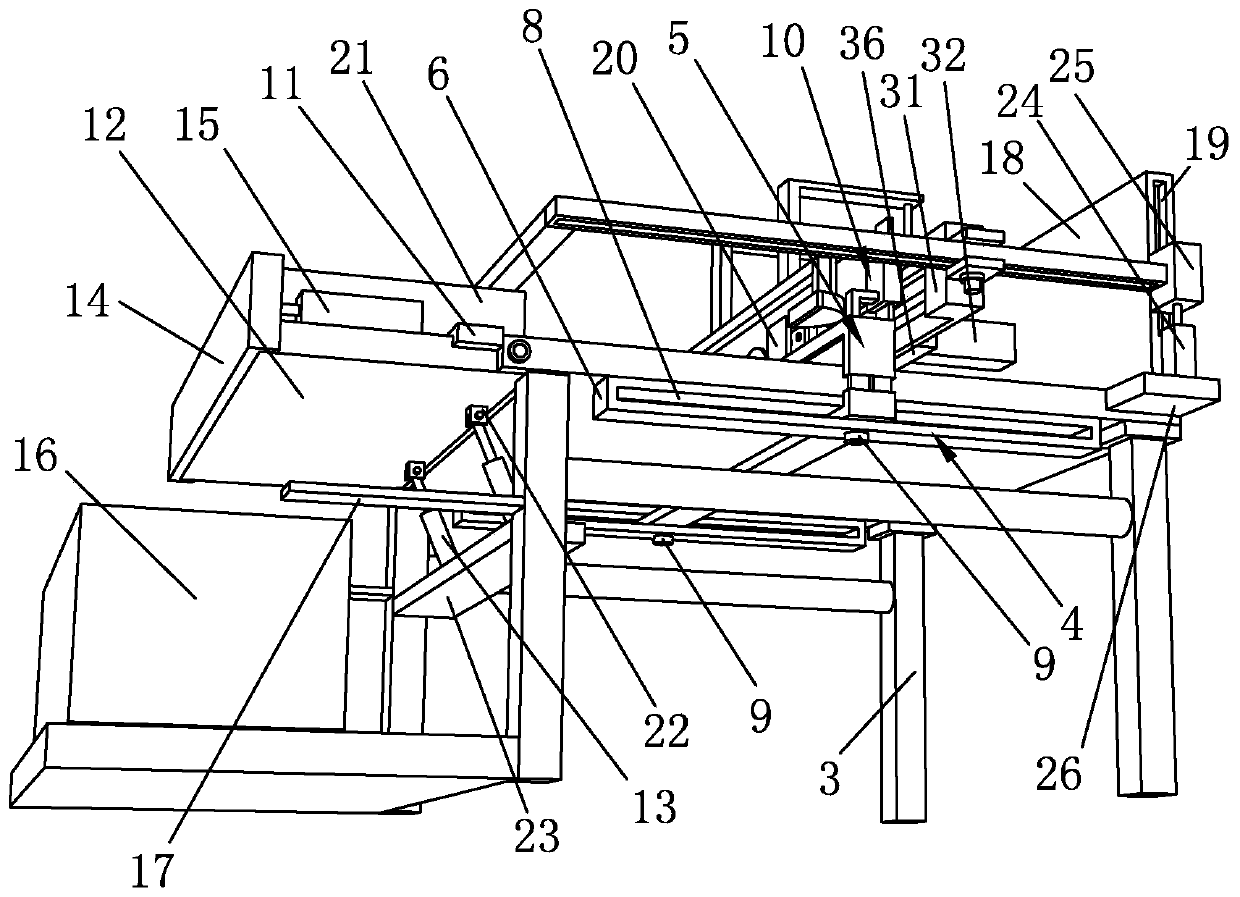

[0030] Such as Figure 1 to Figure 7 As shown, it is a cutting machine for the production of hardware accessories according to the present invention, which includes a cutting table 1 and a cutting head group 2. Support legs 3 are evenly arranged on the bottom surface of the cutting table 1, and a positioning assembly 4 is arranged on the cutting table 1. The positioning assembly 4 includes a positioning pallet 5, a sliding frame 6 and a positioning scale 7, the positioning pallet 5 is arranged horizontally on the cutting table 1, the sliding frame 6 is symmetrically arranged on the left and right sides of the bottom surface of the cutting table 1, and the two ends of the positioning pallet 5 are respectively It is clamped in the chute 8 of the two sliding frames 6, and the positioning clamping plate 5 is limited and fixed with the sliding frame 6 by the limit screw 9, and the positioning scale 7 is movably connected with the positioning clamping plate 5 through the connecting p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com