The method of preventing the cracks in the connection between the concrete structure and the back-filling wall

A technology for connecting parts and filling walls, which is used in building components, building insulation materials, etc., can solve problems such as poor connection of connecting parts, achieve ideal crack resistance, simple process, and solve the effect of poor combination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

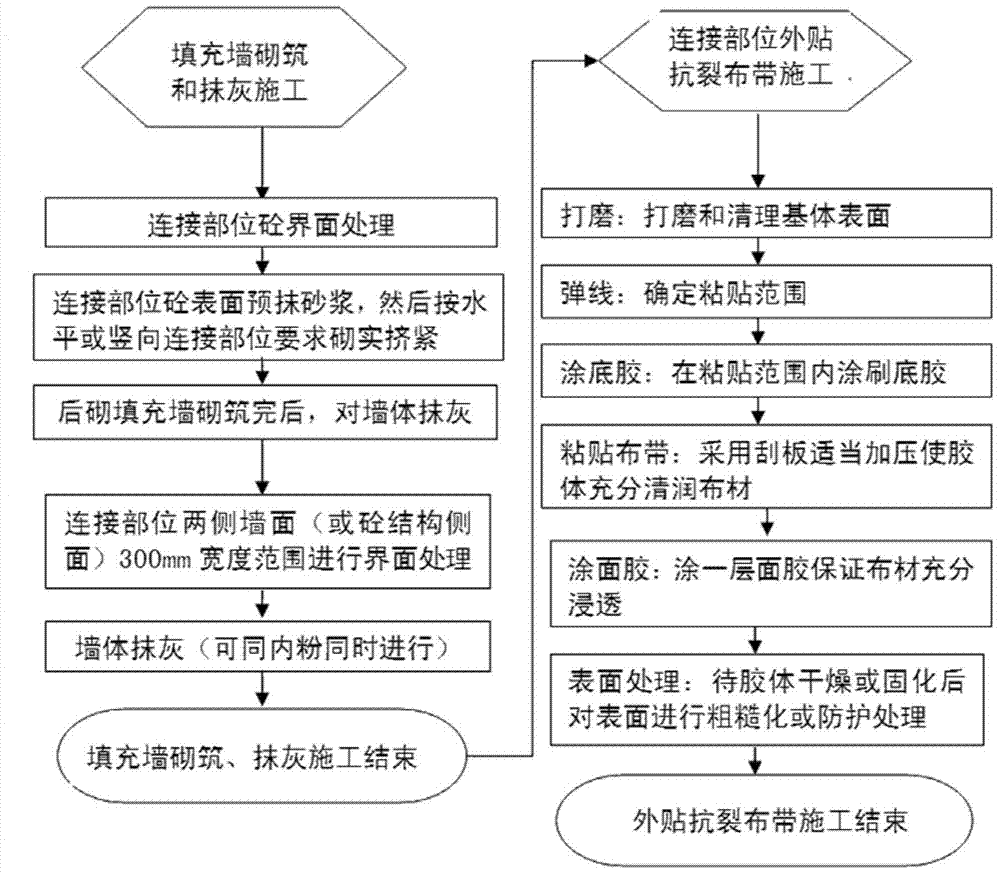

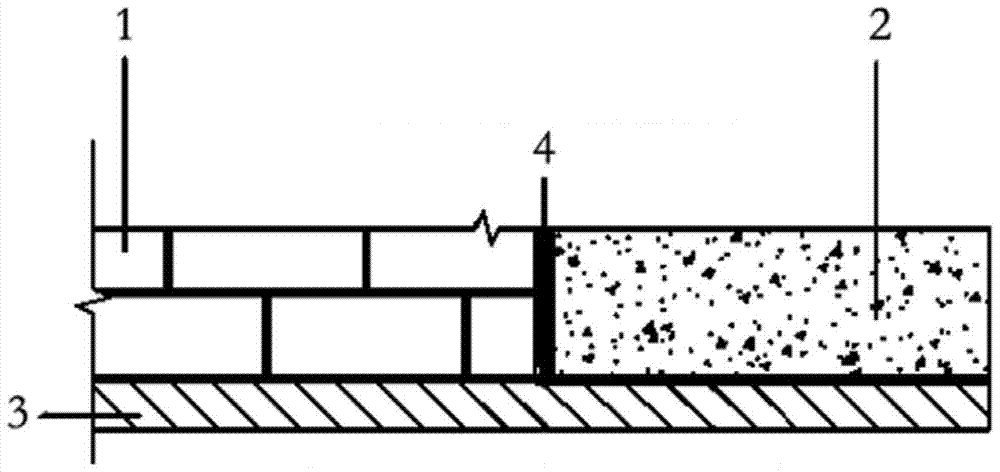

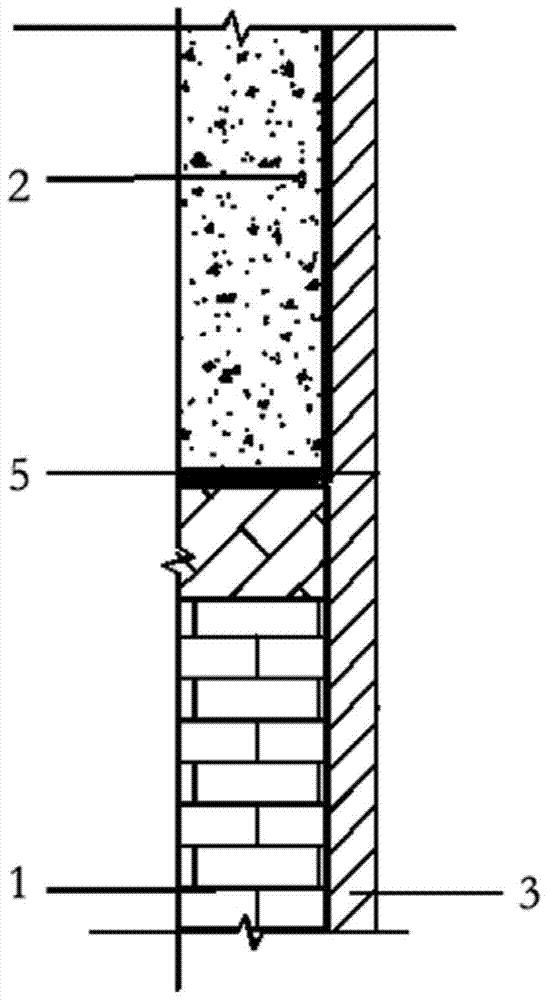

[0042] refer to figure 1 The method for preventing cracks at the joint between the concrete structure and the backfill wall of the present invention mainly includes three steps: masonry construction of the fill wall, plastering construction of the fill wall, and construction of anti-crack tape on the joint. Each step is described in detail below.

[0043] 1. Masonry construction of infill wall

[0044] 1. Interface processing

[0045] Before masonry, brush the concrete interface of the connection part with cement mortar glue, and the thickness of the cement mortar glue brush is ≤3.0mm.

[0046] The composition and weight ratio of cement mortar glue are:

[0047] 901 construction glue: cement: sand = 1:1.5:1.

[0048] It has been verified that the cement mortar glue of this composition has high bonding strength.

[0049] 2. Pre-plast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com