Automatic centering clamping mechanism with self-locking function

An automatic centering and clamping mechanism technology, applied in the direction of workpiece clamping devices, manufacturing tools, etc., can solve problems such as difficult to ensure the position, difficult to twist the handwheel, and difficult to center, so as to ensure that the compression is in place and good self-locking performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

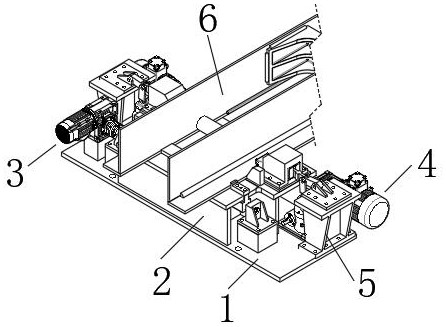

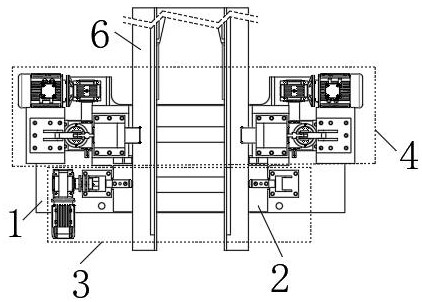

[0021] Such as Figure 1-6 It is a structural schematic diagram of the present invention, a self-locking automatic centering clamping mechanism, including a centering clamping base 1, a support plate 2 is welded on the centering clamping base 1, and the outer end of the support plate 2 has There are clamping assemblies 4 on both sides of the centering assembly 3 and the support plate 2 .

[0022] When this self-locking automatic centering clamping mechanism is in use, the centering assembly 3 of the device will center the workpiece 6 placed on the support plate 2, that is, to place the workpiece on the support plate 2 In order to ensure the accuracy of machining, after the centering is completed, the workpiece 6 is clamped by the clamping assembly to facilitate subsequent processing.

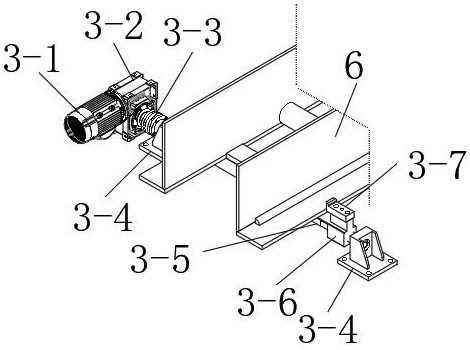

[0023] According to another embodiment of the present invention, it further includes that the centering assembly 3 includes a centering motor 3-1, and a centering reducer 3-2 is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com