A stamping method for stamping large metal sheets

A metal sheet and metal sheet technology, applied in metal processing equipment, forming tools, feeding devices, etc., can solve the problems of high processing cost, error accumulation, no involvement, etc., and achieve the effect of ensuring precision and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

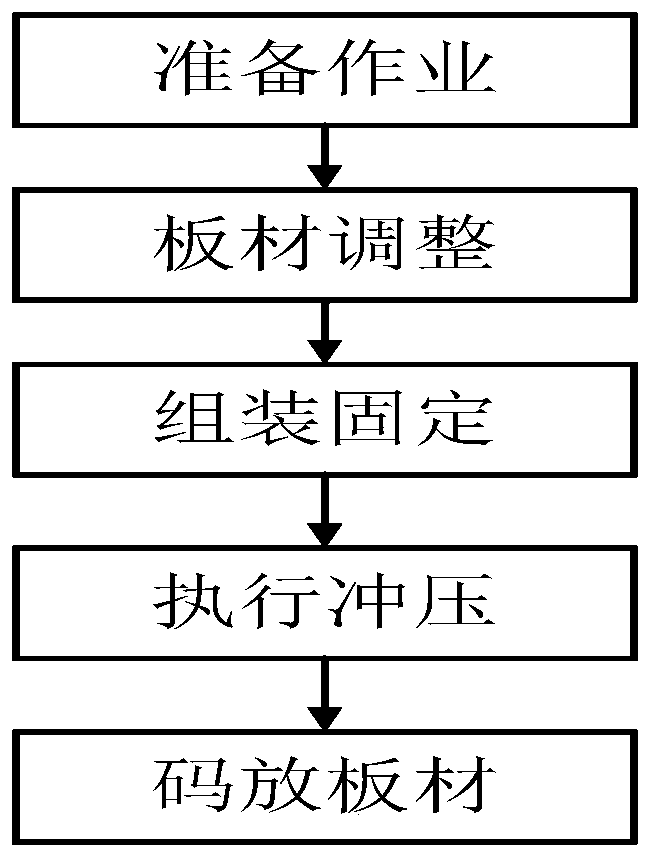

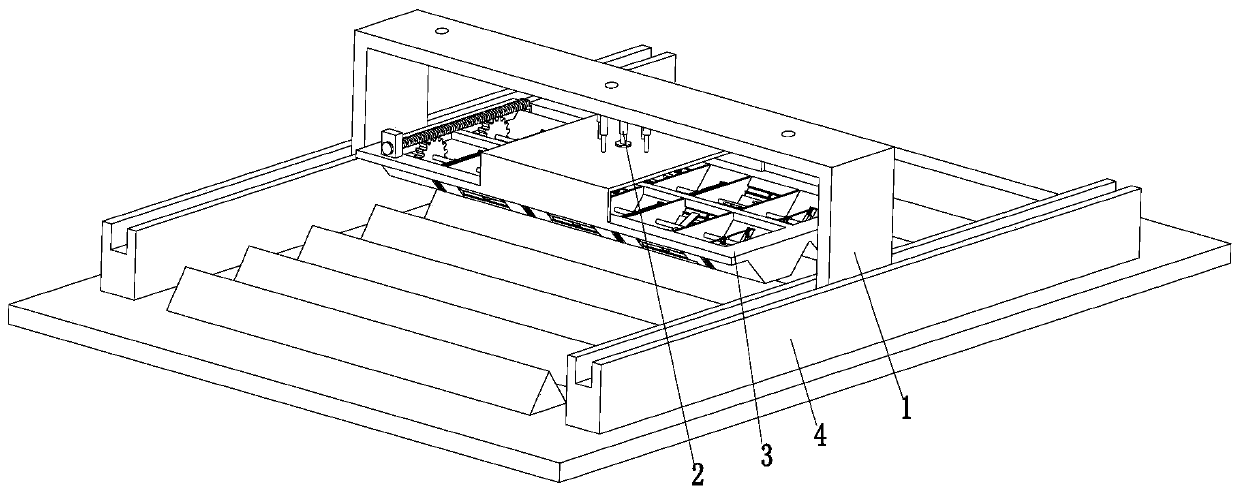

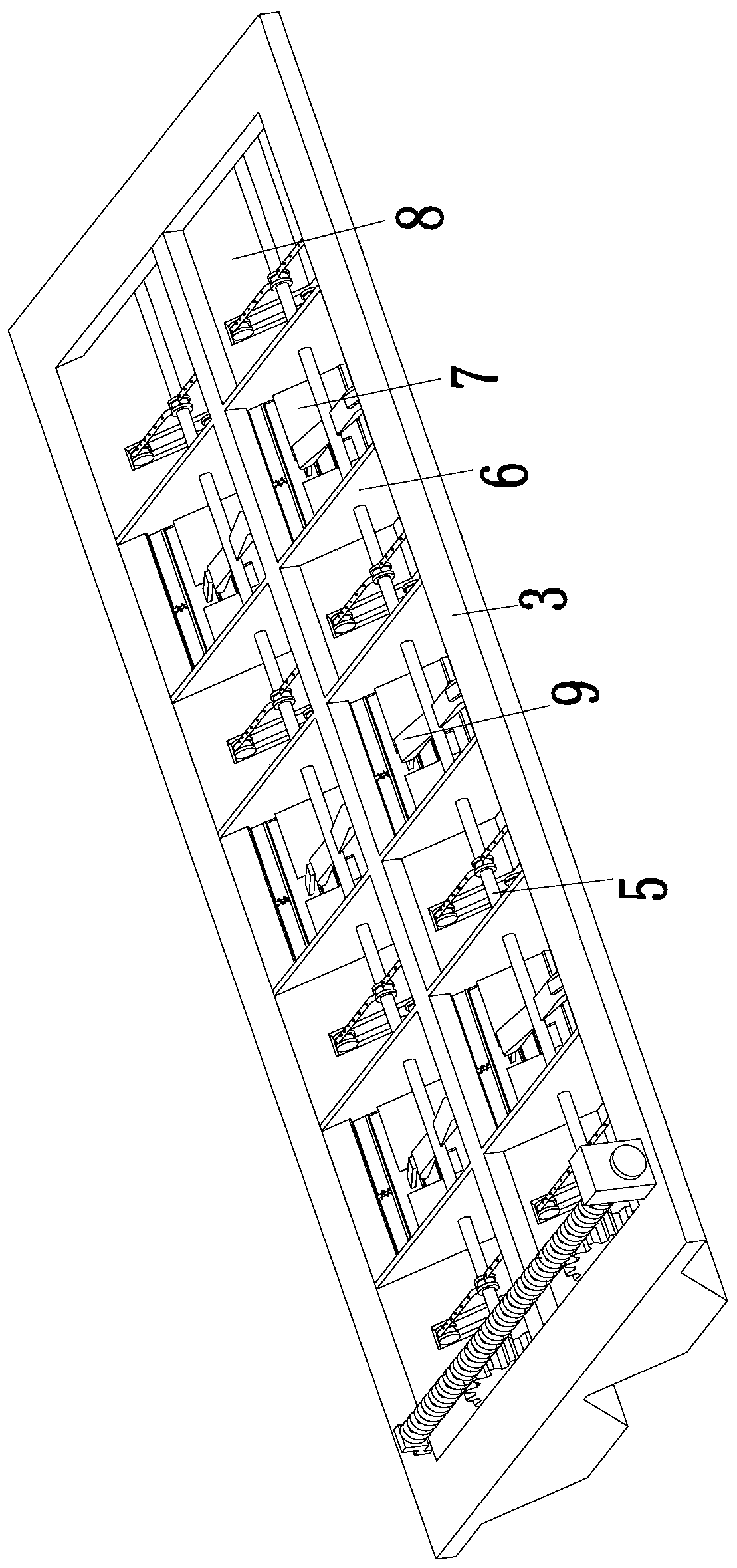

[0034] Such as Figure 1 to Figure 5 As shown, a stamping method for stamping a large metal sheet mainly includes the following stamping steps.

[0035] Step 1, preparation work; select a forming block with a V-shaped structure and fix it on the forming plate 4 for V-shaped stamping of the metal sheet.

[0036] Step 2, plate adjustment; laying the metal plate on the forming plate 4 , and using a ruler to control the adjustment of the metal plate to a position parallel to the forming plate 4 .

[0037] Step 3, assemble and fix; fix the mobile bracket 1 on the self-propelled gantry hanger by screw fixing, adjust the position of the mobile bracket 1 so that the extrusion molding block 3 is located at a position where it can cooperate with the forming ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com