Swing check valve

A check valve and swing-type technology, applied in valve details, control valves, valve devices, etc., can solve problems such as reduced service life, valve damage, and high impact force on the sealing surface of the valve seat, so as to prevent damage to the sealing surface, Avoid rapid closing and prevent water hammer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

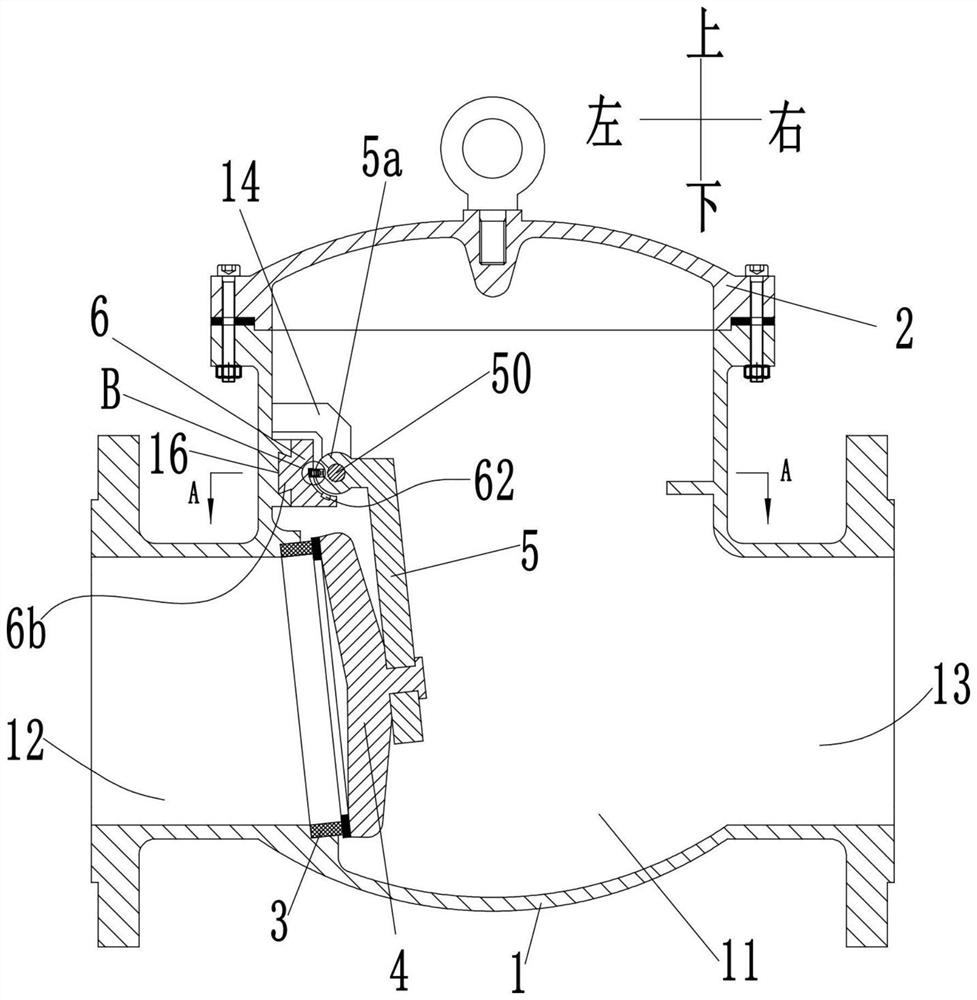

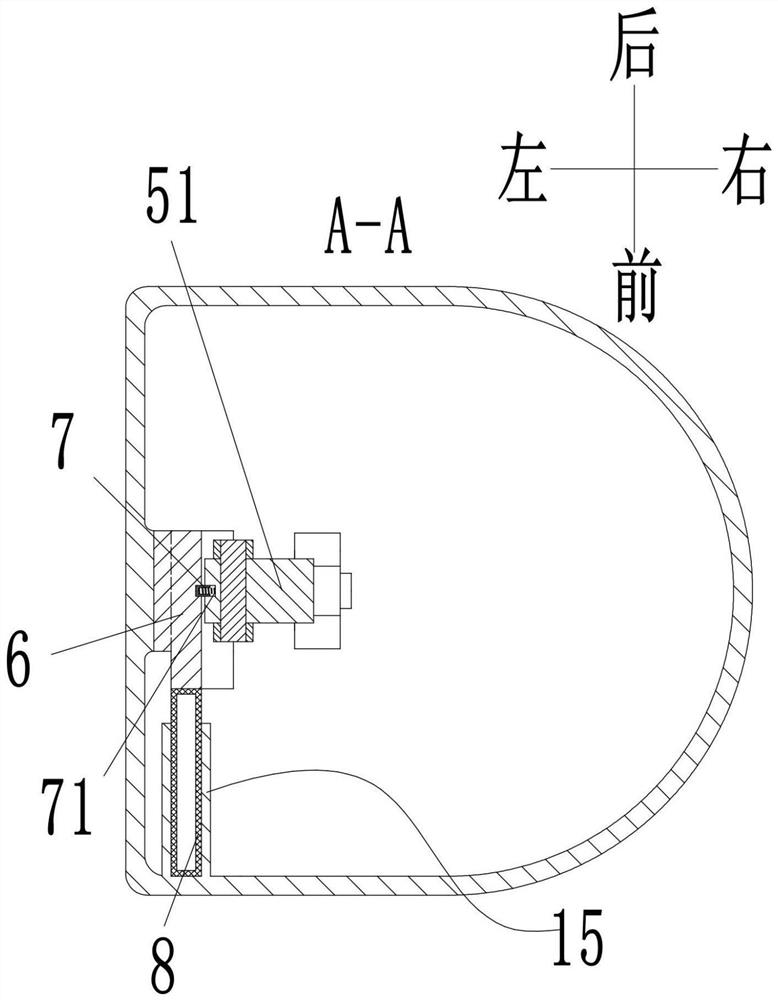

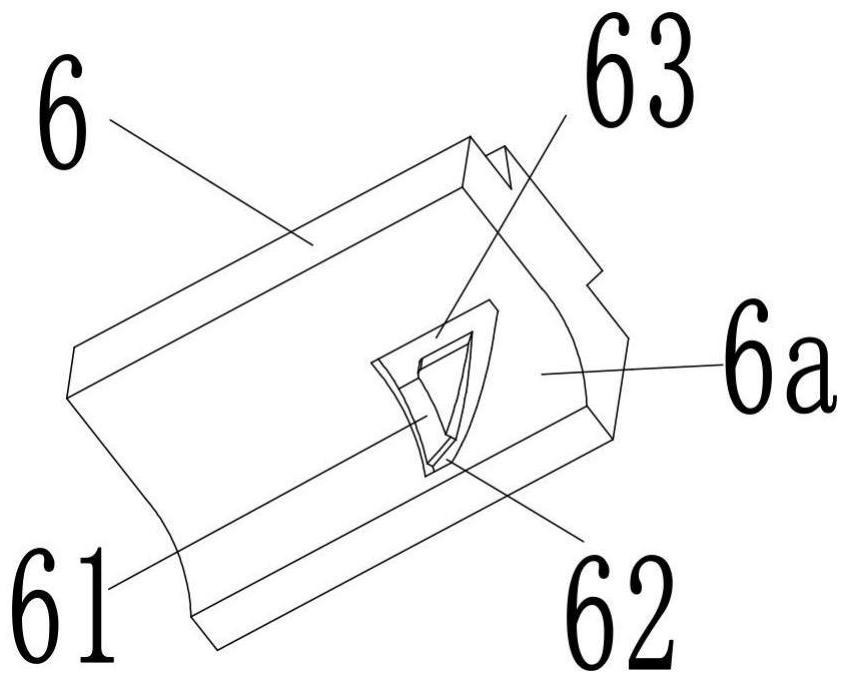

[0019] see Figure 1-5 As shown, a swing check valve includes a valve body 1, the valve body 1 is provided with a valve chamber 11, and the side of the valve body 1 is provided with an inlet pipe 12 and an outlet pipe communicated with the valve chamber 11. 13. The upper opening of the valve cavity 11 is fixed with a bonnet 2, and the left side wall of the valve cavity 11 is provided with two struts 14 above the inlet pipe 12, and the two struts 14 are vertical to the A horizontal shaft 50 is arranged in the axial direction of the inlet pipe 12, and a shaft sleeve 5a is rotatably connected to the shaft shaft 50, and a rocker 5 is extended outside the shaft sleeve 5a, and the rocker 5 is positioned away from the support bar. 14 is fixedly installed with a disc 4 for controlling the on-off of the inlet pipe 12; the left side wall of the valve cavity 11 is slidably connected with a pressure block 6 along the axial direction of the shaft 50 under the support rod 14, and the valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com