Petri network-based chemical leakage event emergency disposal process performance analysis method

A technology of emergency response and analysis methods, applied in the field of business process management, can solve the problems of lack of modeling and analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0081] The present invention will be further described below in conjunction with specific embodiments.

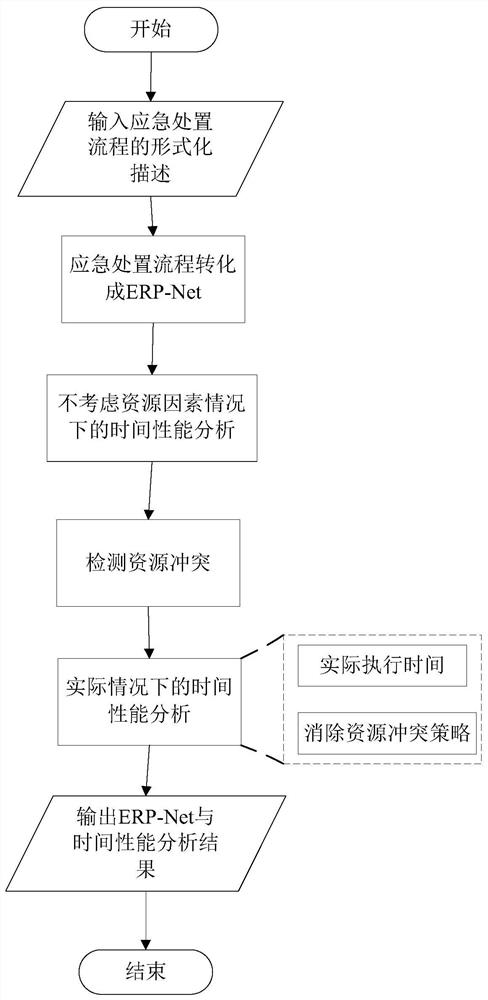

[0082] like figure 1 As shown, the Petri net-based method for analyzing the performance of the emergency disposal process for chemical leakage incidents provided in this embodiment first obtains a formal description of the emergency disposal process for chemical leakage incidents, and then converts the emergency disposal process for chemical leakage incidents into ERP. -Net, and finally based on the obtained ERP-Net to analyze the time performance of the emergency response process for chemical leakage incidents, which includes the following steps:

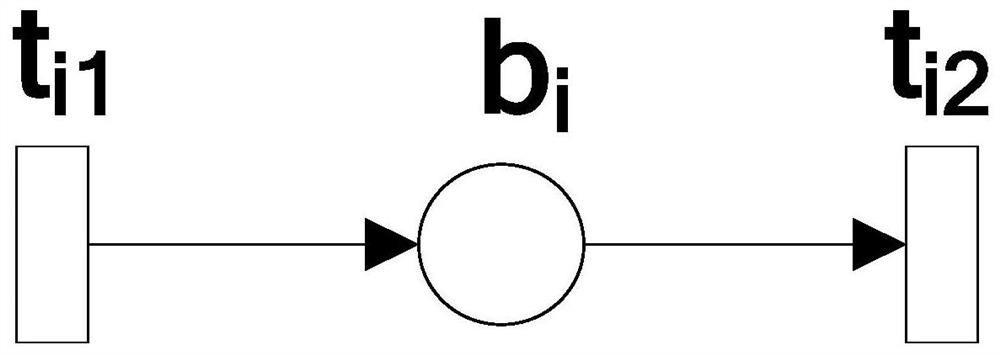

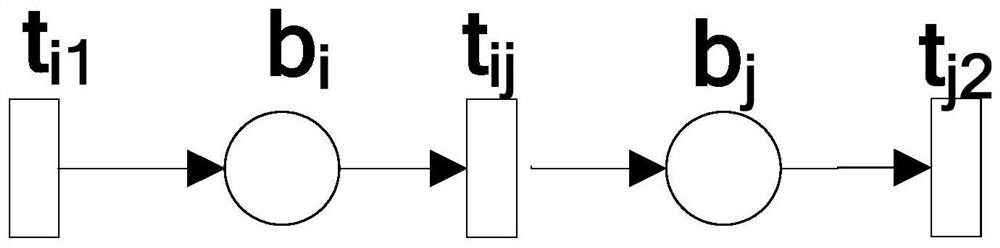

[0083] 1) Analyze the emergency tasks and associated time information and resource information involved in the chemical spill emergency response process; the emergency tasks and associated time information and resource information involved in the chemical spill emergency response process are subject to Formal description of eme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com