Envelope type packaging machine

A packaging machine and envelope technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of pattern ghosting, error affecting the corresponding position of the pattern, etc., achieve clear pattern printing, improve conveying efficiency, and reduce conveying deviation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

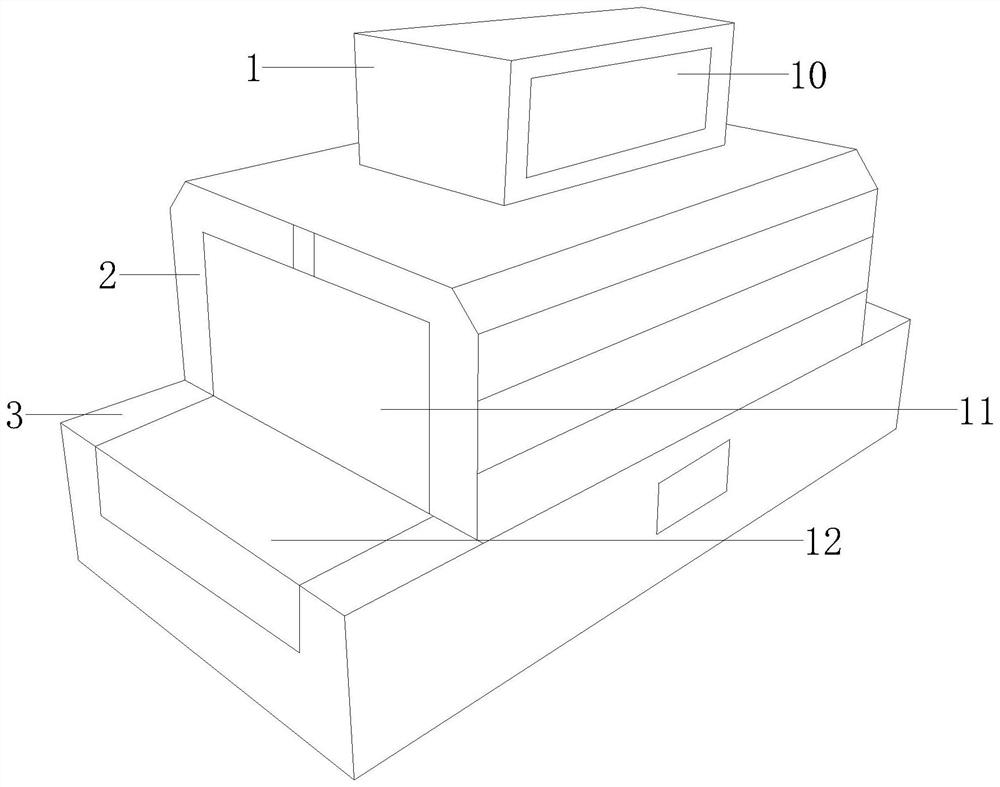

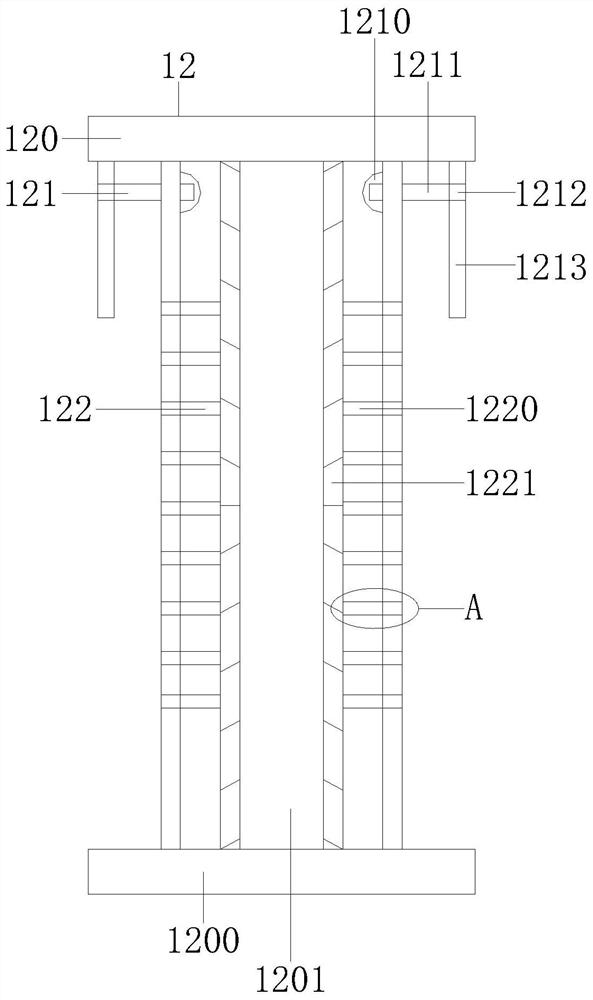

[0025] Example 1 see figure 1 , 2 , the present invention provides a technical solution for an envelope packaging machine: its structure includes a control box 1, a machine cover 2, and a frame 3, the control box 1 is locked with the machine cover 2, and the machine cover 2 is installed and connected with the frame 3 , the control box 1 is provided with a display panel 10, the hood 2 is connected with a stopper 11, the frame 3 is equipped with a conveying device 12, and the conveying device 12 includes a conveying rack 120, a detection side frame 121, Transport frame 122, the transport frame 120 is installed and connected with the detection side frame 121, the transport frame 122 is installed on the transport frame 120, the transport frame 120 includes an end frame 1200, a transport main frame 1201, the end The frame 1200 is installed and connected with the conveying main frame 1201, and the detection side frame 121 includes an installation side cover 1210, a side-mounted cr...

Embodiment 2

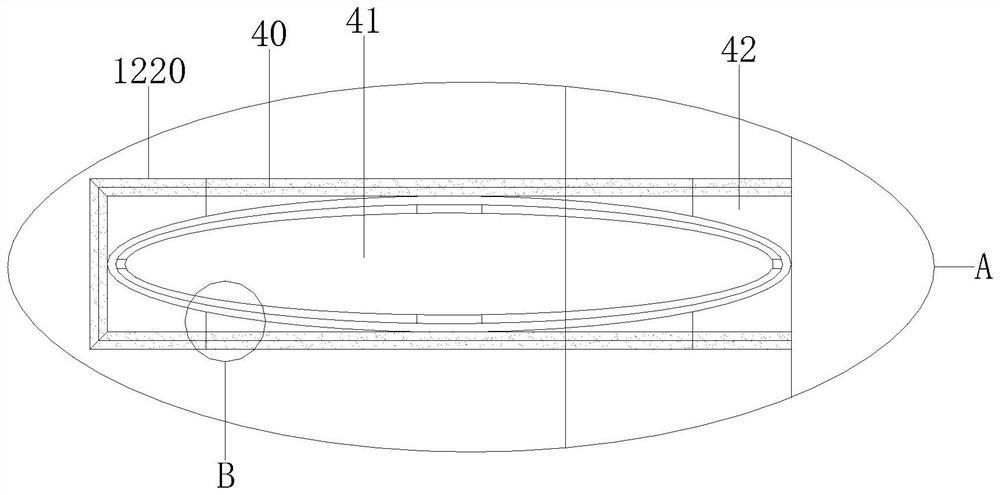

[0027] Example 2 see Figure 3-5 , the present invention provides a technical solution for an envelope packaging machine: the structure of the adjustment rod structure 1220 includes a lifting platform frame 40, a shaft roller 41, and a structural slide plate 42, and the lifting platform frame 40 is connected to the structural sliding plate 42. The shaft roller 41 is installed and connected with the lifting platform frame 40 and the structural slide plate 42. The lifting platform frame 40 includes an upper lifting platform frame 400, a bottom lifting platform frame 401, and a sliding track 402. The upper lifting platform frame 400 and the bottom lifting platform frame 401 is connected by sliding track 402, and the shaft roller 41 includes a shaft roller body 410, a shaft roller surrounding frame 411, and a transmission shaft 412, and the shaft roller body 410 and the shaft roller surrounding frame 411 are installed and connected through a transmission shaft 412. Described struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com