A kind of support for mine concrete support engineering and its support method

A concrete and engineering technology, used in pillars/supports, roof beams supporting mine roofs, mining equipment, etc. The effect of the collapse phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

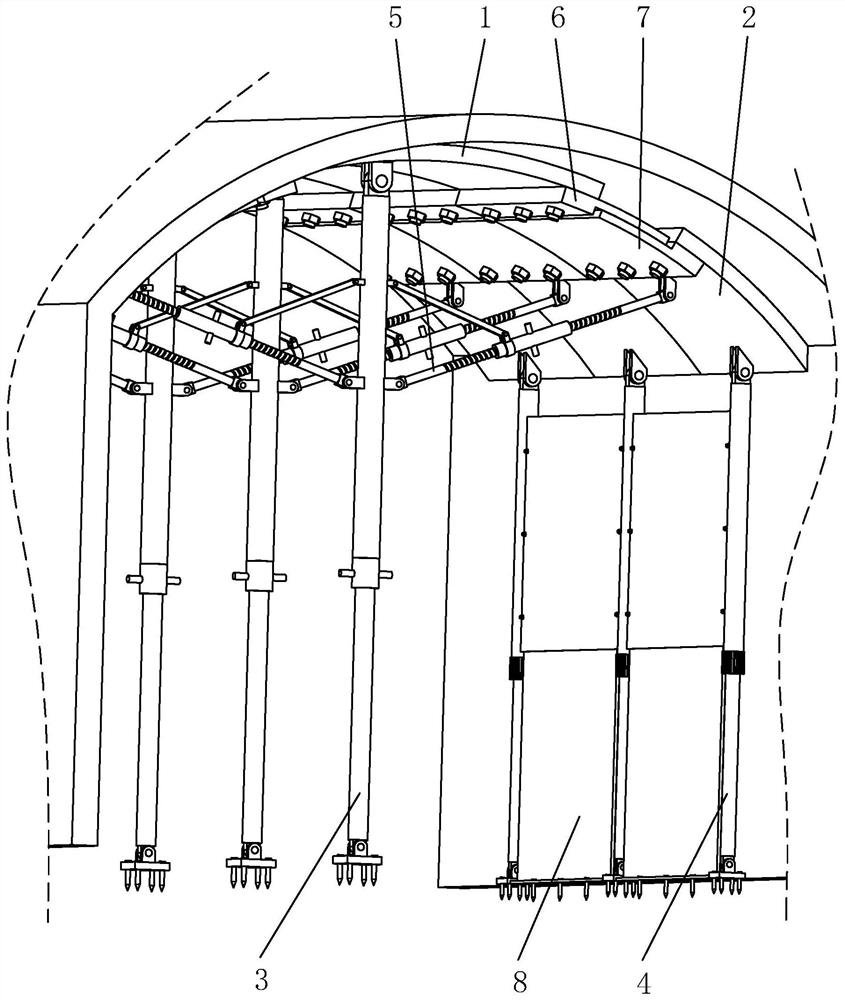

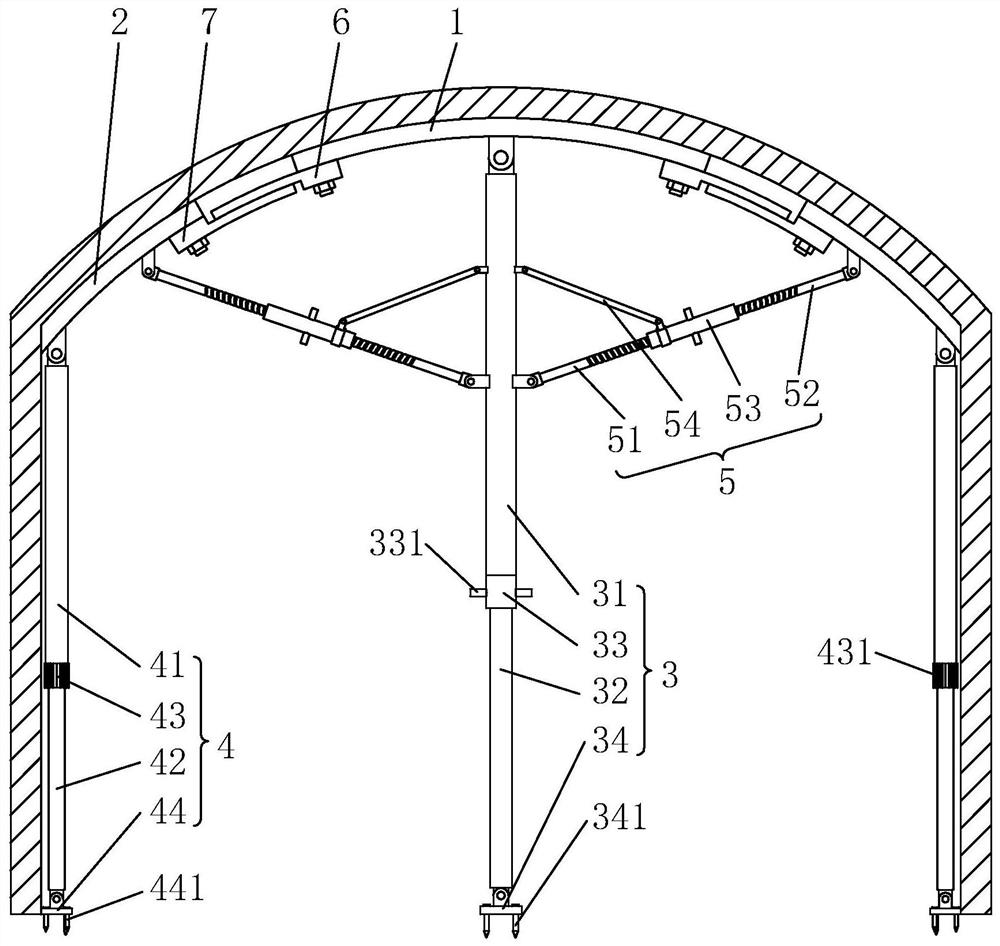

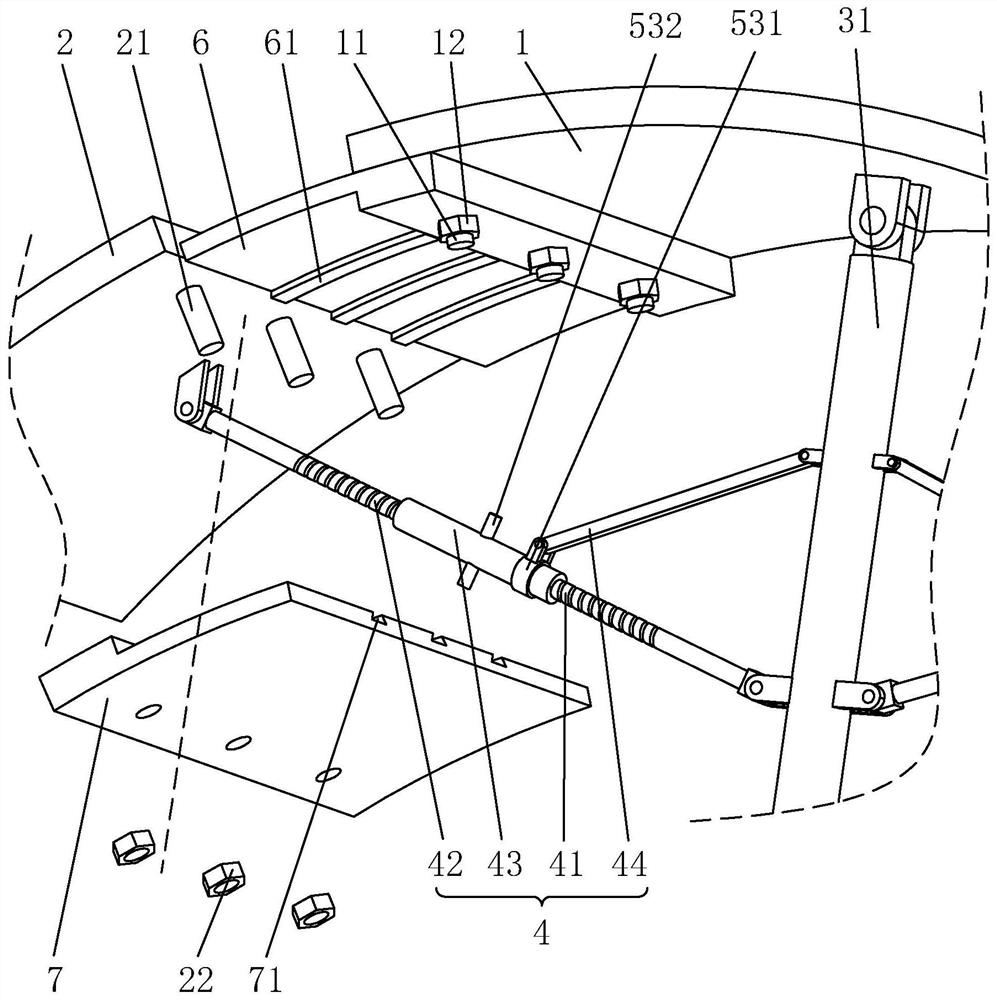

[0041] Attached to the following Figure 1-4 This application will be described in further detail.

[0042] The embodiment of the present application discloses a support for mine concrete support engineering. refer to figure 1 A support for a mine concrete support project includes a plurality of first support plates 1 that are arranged in order along the length of the mine. The bottom of the board 1 is provided with a first support portion 3 , the bottom of the second support board 2 is provided with a second support portion 4 , and a connection portion 5 is provided between the first support portion 3 and the two second support boards 2 .

[0043] refer to figure 2 , the longitudinal sections of the first support plate 1 and the second support plate 2 are curved upwards, and the first support portion 3 includes a first support rod 31, a first adjustment rod 32, a first adjustment sleeve 33 and a first bearing The pressing plate 34, the first support rod 31, the first adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com