Waste material blockage detection device and method

A technology for clogging detection and waste, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as inability to monitor, limit detection methods, and inability to install photoelectric sensors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

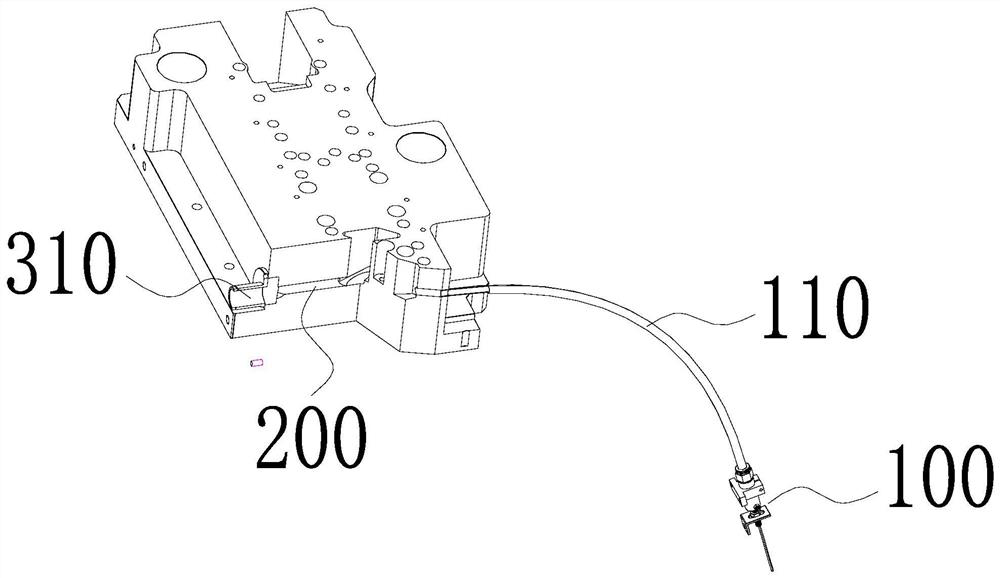

[0027] A waste clogging detection device for a waste channel 200 with unidirectional air flow comprising:

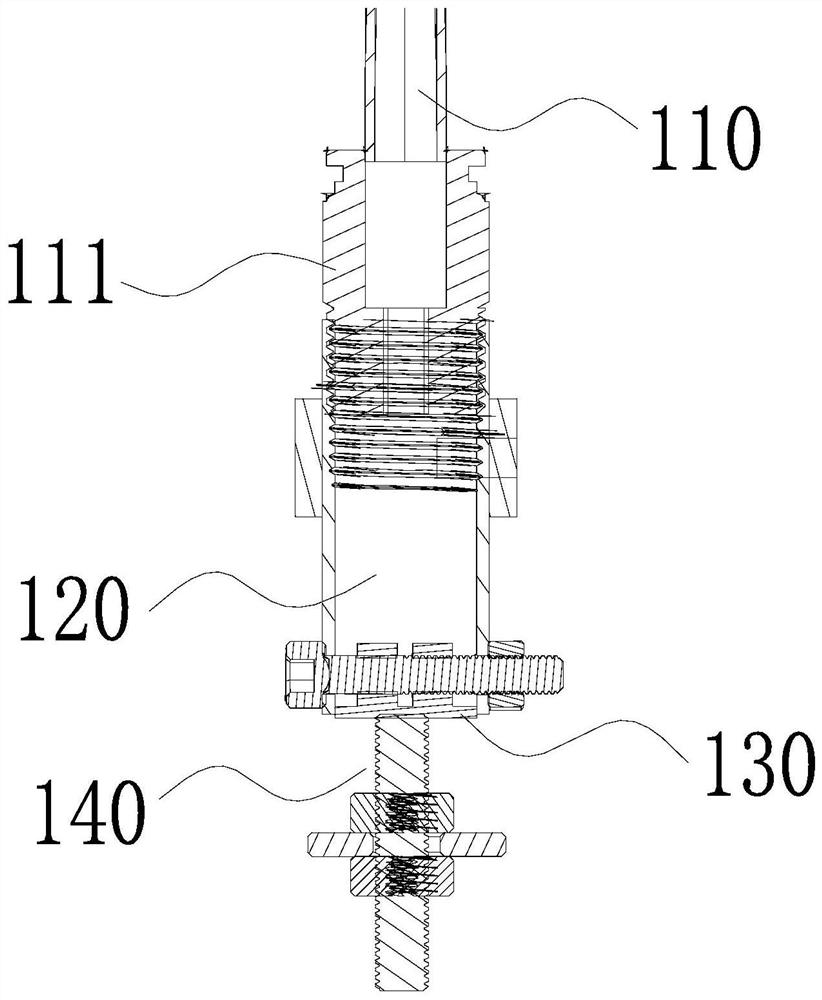

[0028] An air connection pipe 110, the air connection pipe 110 is used to communicate with the waste channel 200;

[0029] A joint cavity 120, the joint cavity 120 communicates with the air connection pipe 110, and a plectrum 130 is arranged in the joint cavity 120;

[0030] Proximity sensor 140, the proximity sensor 140 is connected with the paddle 130, when the air flow weakens or stops, the paddle 130 contacts with the proximity sensor 140 to generate an alarm signal.

[0031] Along the direction of the unidirectional air flow, an air end and an air intake end are divided, the air outlet end of the joint cavity 120 is in airtight communication with the air connection pipe 110 through the air pipe joint, and the air intake end of the joint cavity 120 When there is unidirectional air flow in the joint cavity 120 , the intake air will lift the paddle 130 away from the p...

Embodiment 2

[0039]A method for detecting waste blockage, using the waste blockage detection device of embodiment 1, comprising the steps of:

[0040] (1) The joint cavity is connected with the waste channel; the suction fan creates unidirectional air flow in the waste channel;

[0041] (2) When the waste channel is unblocked, in the direction of the air flow created by the suction fan, the paddle moves away from the proximity sensor with the air flow; when the air flow changes and the position of the paddle changes to trigger the proximity sensor, it is determined that the waste channel is blocked .

[0042] (3) The proximity sensor sends an output signal to the control module, and the control module outputs an alarm or shutdown command according to the output signal.

[0043] The waste blockage detection method can use the paddle to monitor the unidirectional air flow (i.e. the air flow in the waste channel) flowing in the air pipe. When the continuous air flow is maintained in the wast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com