PP color master batch and preparation method thereof

A technology of color masterbatch and talcum powder masterbatch, which is applied in the field of PP color masterbatch and its preparation, can solve the problems of low-temperature brittleness and easy deformation, and achieve the effects of saving processing costs, solving the problem of low-temperature brittleness, and improving the normal temperature modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

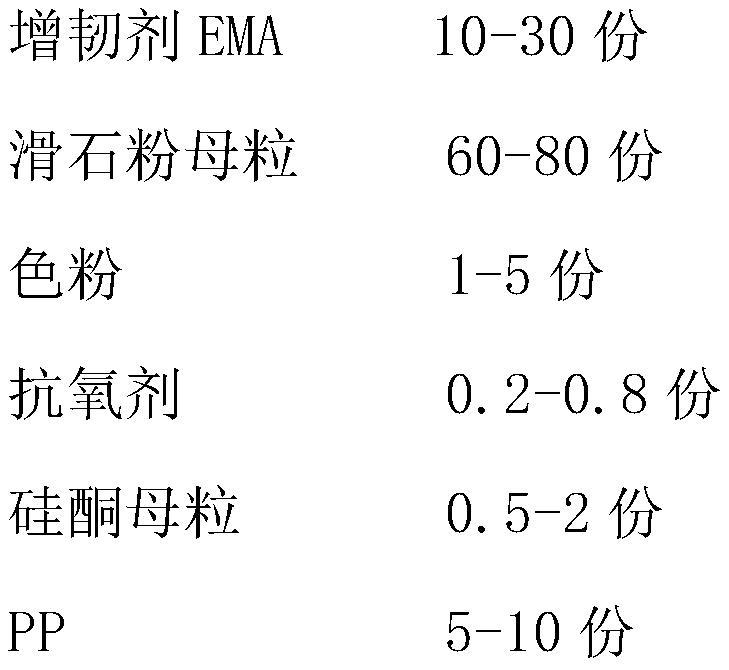

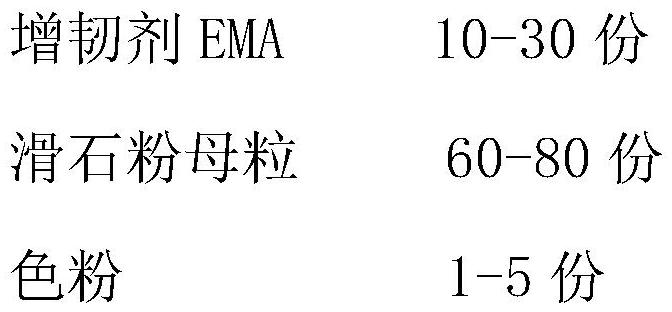

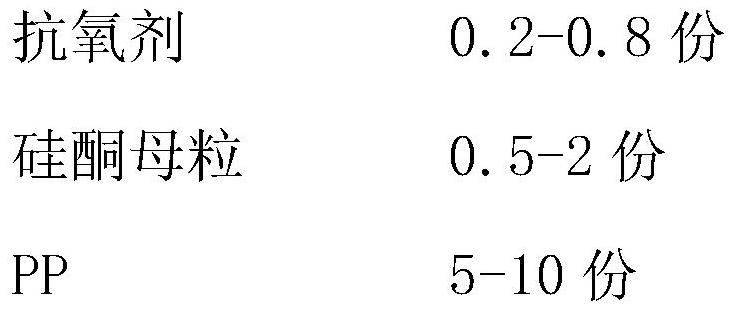

[0021] PP masterbatch according to the following formula

[0022]

[0023]

[0024] Prepared by the following method:

[0025] 1) The powder is dried and activated in a high mixer; the pellets are dry-fried in a dryer;

[0026] 2) Put the processed base material, auxiliary material, auxiliary agent and other raw materials into the mixer for mixing after being measured according to the formula ratio;

[0027] 3) Put the mixed materials into the twin-screw extruder to knead and extrude the strands to granulate. Zone temperature is 200°C, zone 5 temperature is 200°C, zone 6 temperature is 200°C, zone 7 temperature is 200°C, head temperature is 190°C, melt temperature is 205°C, host speed is 280-300rpm;

[0028] 4) The extruded material is cooled, air-dried, pelletized, dried and packed into storage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural modulus | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com