Anti-falling hydraulic lifting mechanism and equipment

A hydraulic lifting and anti-falling technology, applied in the direction of lifting frame, lifting device, etc., can solve the problems of poor safety, inability to perform secondary protection during the landing process, and inability to perform anti-falling protection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

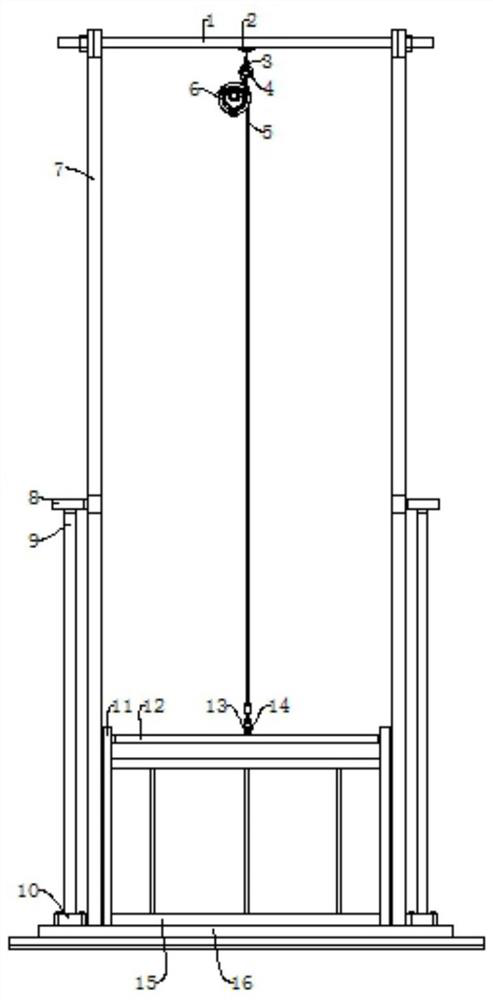

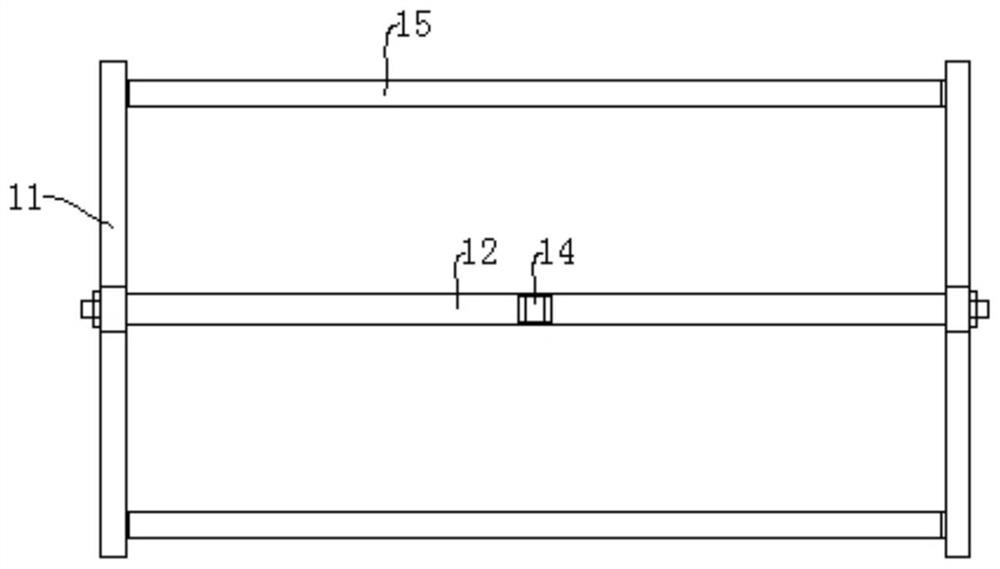

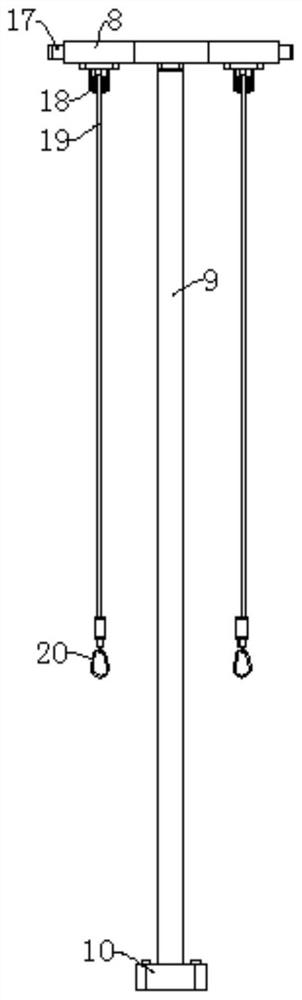

[0020] see Figure 1~3 , in the embodiment of the present invention, a kind of anti-falling hydraulic lifting mechanism and equipment, comprises lift frame 7, and hanger bar 1 is installed on the top between lift frame 7, and hanger bar 1 is convenient to install and fix with the first connecting plate 2, and hanger bar The middle part of the bottom end of 1 is equipped with a first connecting plate 2, and the bottom of the first connecting plate 2 is equipped with a first suspension ring 3, which is convenient for the installation of the self-locking spring balancer 6, and a self-locking spring balancer 6 is installed on the first suspension ring 3. The spring balancer 6, the self-locking spring balancer 6 is used to carry out self-locking balance control to the lifting platform 15, the outside of the self-locking spring balancer 6 is equipped with a hook 4, the hook 4 is suspended and connected with the first suspension ring 3, and the self-locking spring balance The inside ...

Embodiment 2

[0023] see Figure 1~3 , in the embodiment of the present invention, a kind of anti-falling hydraulic lifting mechanism and equipment, comprises lift frame 7, and hanger bar 1 is installed on the top between lift frame 7, and hanger bar 1 is convenient to install and fix with the first connecting plate 2, and hanger bar The middle part of the bottom end of 1 is equipped with a first connecting plate 2, and the bottom of the first connecting plate 2 is equipped with a first suspension ring 3, which is convenient for the installation of the self-locking spring balancer 6, and a self-locking spring balancer 6 is installed on the first suspension ring 3. The spring balancer 6, the self-locking spring balancer 6 is used to carry out self-locking balance control to the lifting platform 15, the outside of the self-locking spring balancer 6 is equipped with a hook 4, the hook 4 is suspended and connected with the first suspension ring 3, and the self-locking spring balance The inside ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com