Anti-falling type rim mounting structure

A technology for installing structures and rims, applied in the directions of rims, transportation and packaging, vehicle parts, etc., can solve the problems of the lock ring not being locked in place, the lock ring coming off the slot, affecting the inflation effect, etc. Potential safety hazards and the effect of saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

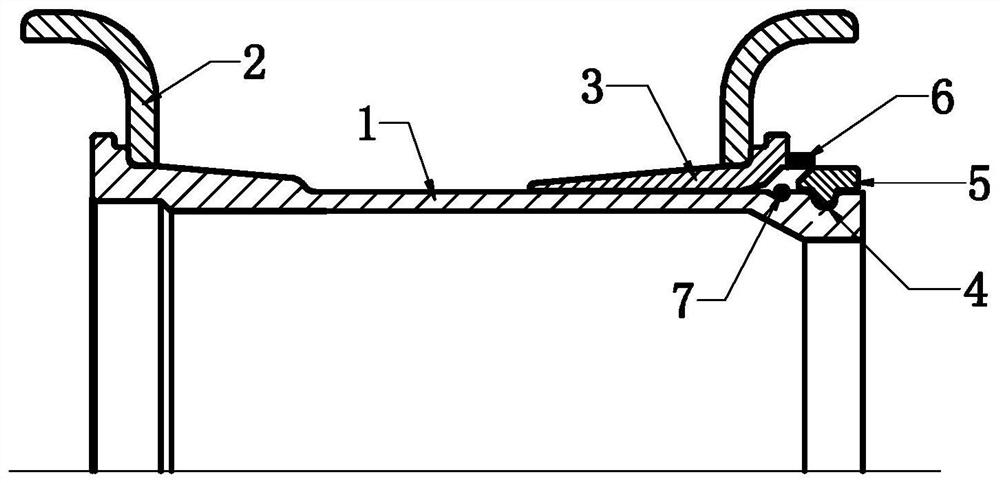

[0020] Such as figure 1 As shown, the anti-off rim installation structure of this embodiment includes a rim 1, a left rim that can be placed on the left end of the rim, and a right rim that can be placed on the right end of the rim. Between the seat ring 3, the root of the seat ring 3 is provided with a flat section that matches the rim 2, thus greatly improving the fit of the fit and installation, and the end of the seat ring 3 is used to block the right rim to make it The flanging structure that will not fall off, the seat ring 3 has an outer surface that extends obliquely upward from the inside of the rim to the outside of the rim, the center of the rim is defined as the inside of the rim, that is, the part between the two rims is defined as the inside of the rim, and the outside of the rim The part defined as the outer side of the rim, the left edge of the rim 1 is directly set as an outer surface that extends upwardly from the inside of the rim to the outside of the rim, ...

Embodiment 2

[0023] The anti-off rim installation structure of this embodiment includes a rim 1, a left rim that can be placed on the left end of the rim, and a right rim that can be placed on the right end of the rim. The left seat ring, the left edge of the rim 1 is provided with a left seat ring (not shown in the figure) between the rim and the left wheel rim, and the roots of the left seat ring and the right seat ring are provided with a section that is connected with the left wheel rim and the right wheel rim. The plane section that fits the rim, thus greatly improving the fit of the installation. The end of the seat ring 3 has a flanging structure for blocking the right wheel rim so that it will not fall off. Both the left seat ring and the right seat ring have from The inner surface of the rim is inclined upwards to the outer surface of the rim, and the central position of the rim is defined as the inner rim, that is, the part between the two rims is defined as the inner side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com