Rolling bearing fault diagnosis method based on variational Hilbert-Huang transform

A rolling bearing and fault diagnosis technology, which is applied in the testing of mechanical components, pattern recognition in signals, testing of machine/structural components, etc., can solve problems such as insufficient accuracy of early fault detection, improve early fault detection capabilities, and realize The effect of noise suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the accompanying drawings, which cannot be used to limit the protection scope of the present invention. It should be noted that, in the case of no conflict, the embodiments in the present application and various manners in the embodiments can be combined with each other. The drawings in the following description are only some embodiments of the present invention, and those skilled in the art can also obtain other drawings according to these drawings without creative work.

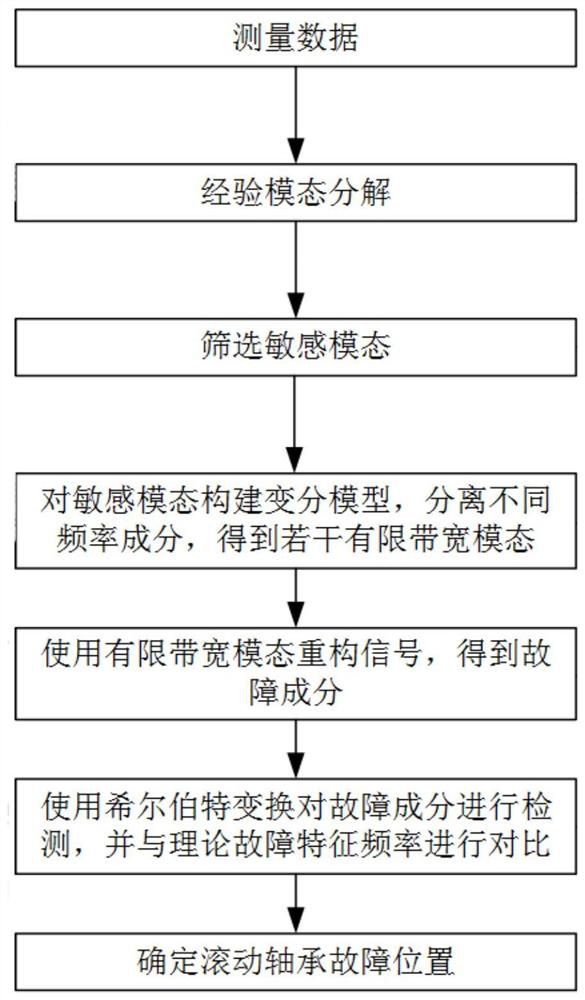

[0031] see figure 1 As shown, a rolling bearing fault diagnosis method based on variational Hilbert-Huang transform shown in this embodiment includes the following steps:

[0032] S1 processes the measurement data of rolling bearings using empirical mode decomposition to obtain several intrinsic mode functions IMF i .

[0033] The measurement data includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com