Fluid machinery system and method for controlling same

A technology of fluid machinery and control methods, which is applied in the direction of liquid variable displacement machinery, pump control, fluid parameters, etc., can solve the problems of maintenance and stop, and achieve the effect of suppressing wear and deterioration and averaging the running time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] In this embodiment, the operation number control device of a gas compression device for compressing air will be described as an example.

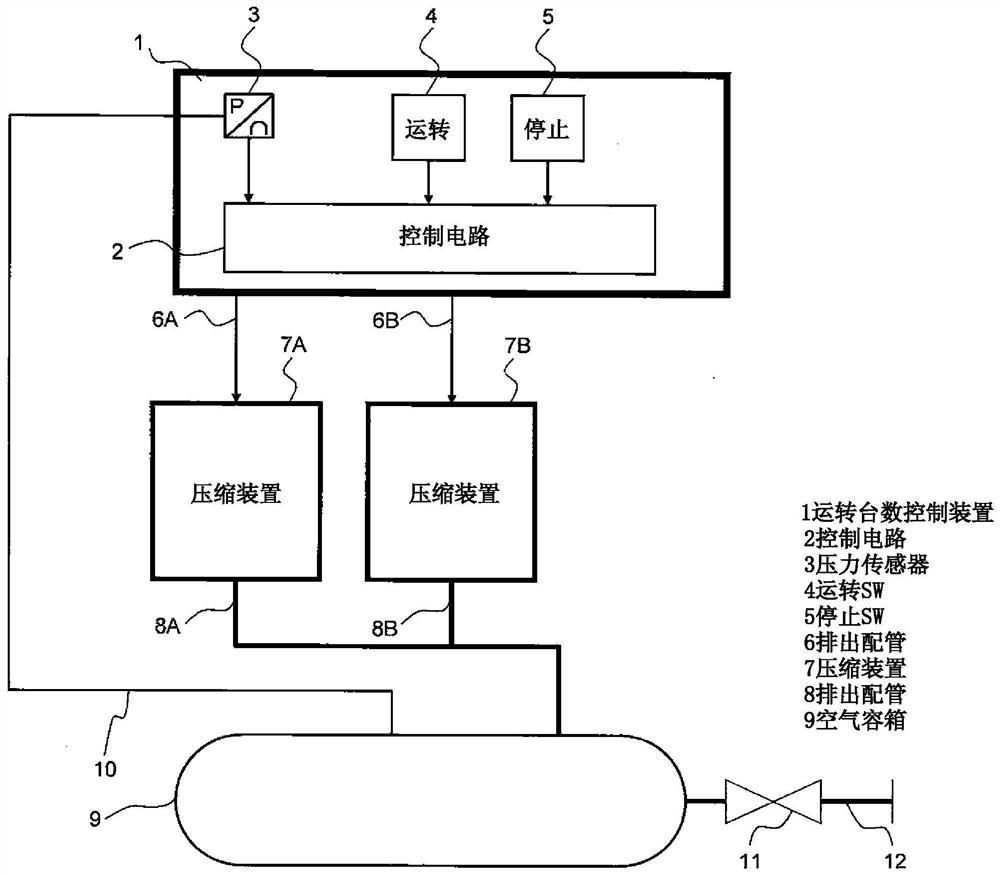

[0026] figure 1 It is a system configuration diagram of the operating number control device of the gas compression device of the present embodiment. figure 1 In the figure, it roughly includes compression devices 7A, 7B, an operation number control device 1 for controlling the operating state of the compression devices, and a tank 9 for storing compressed gas discharged from the compression devices. The above-mentioned operation number control device 1 includes: a pressure sensor 3 for measuring the pressure of the compressed gas stored in the above-mentioned container B; a control circuit 2 for determining the operation number of a plurality of compression devices and the operating compressors according to the pressure information; The operation switch 4 and the stop switch 5 determine the overall working state of the device.

[0...

Embodiment 2

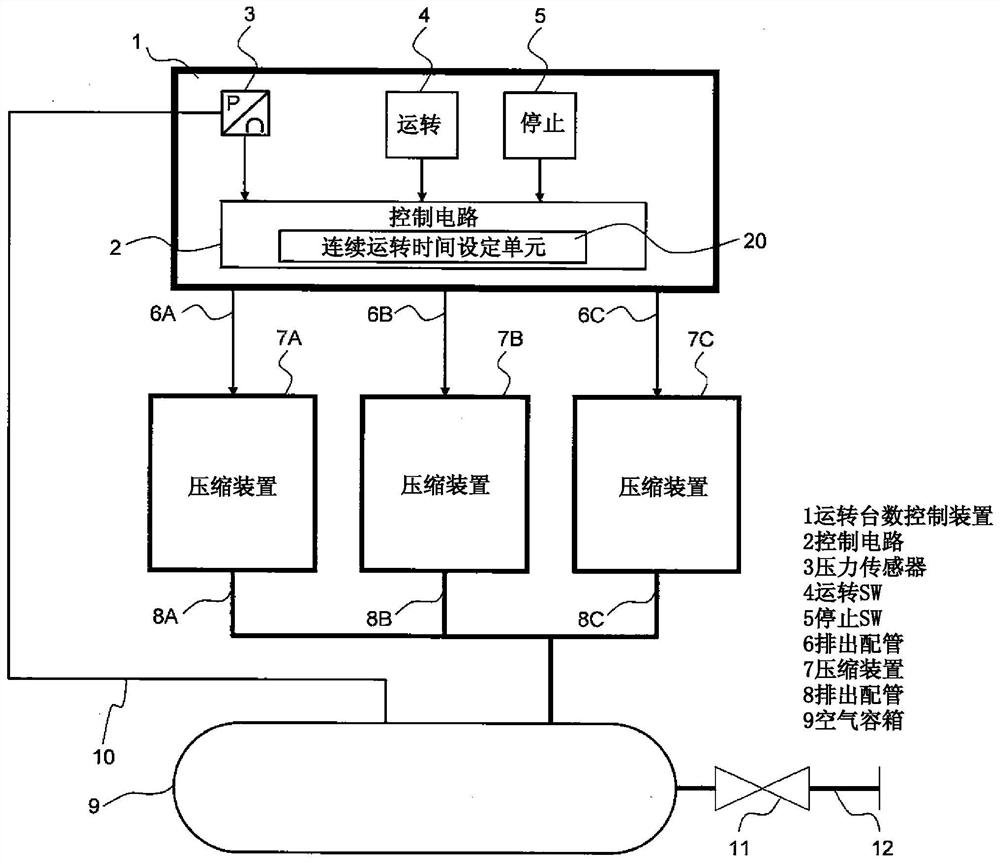

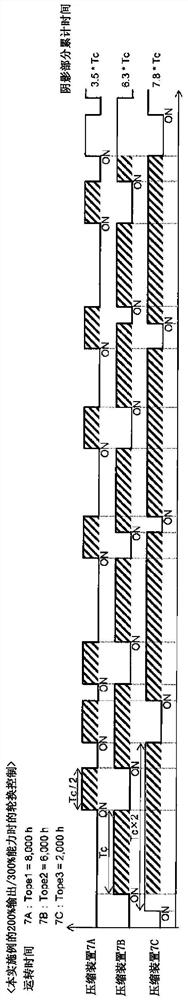

[0037] In the control of compression equipment, when performing rotation and number control, when two compressors reach the specified operating time almost at the same time, if Figure 4 As shown, immediately after the stop of the compression device 7C, it may be operated again as a replacement of the compression device 7A, and a sufficient cooling period may not be ensured. At this time, since the operation / stop operation is performed many times in a short period of time, noise is generated. Therefore, in this embodiment, a function is newly added to the continuous operation time setting unit 20 of the compression device to extend the operation without performing the alternation immediately after the replacement machine stops even if the predetermined operation time is reached.

[0038] based on Figure 5 and Figure 6 The present Example 2 will be described. The continuous operation time setting unit 20 first judges in step 11 whether any one of the compression devices in...

Embodiment 3

[0046] In the prior art and the above-mentioned Embodiment 1 and Embodiment 2, the continuous operating time of the compression device is obtained by multiplying a preset coefficient, but when the total operating time is extremely different, there may be a difference in the total operating time. The averaging of the operating hours of the compression devices may not be completed before the maintenance time of the longest compression device is reached. Therefore, in Embodiment 3, the remaining time Tremain to maintenance can be calculated according to the total operating time of each compression device, the average remaining time Tremain_ave can be calculated, and the operating time of each compression device can be determined according to the ratio of the remaining time Tremain to the average remaining time, thereby enabling Control is performed so that the averaging of the total operating hours of the compression devices is completed before the compression device with the long...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com