Precise Positioning Method for Prefabricated Stairs

A precise positioning and stair technology, which is applied in the processing of building materials, construction, building structure, etc., can solve the problems of insufficient precision of prefabricated stairs, affecting the appearance, and being difficult to repair.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

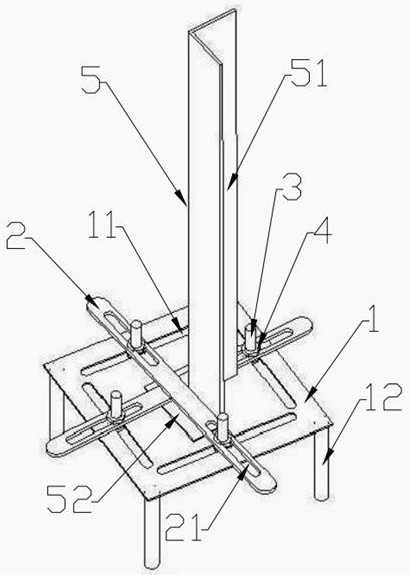

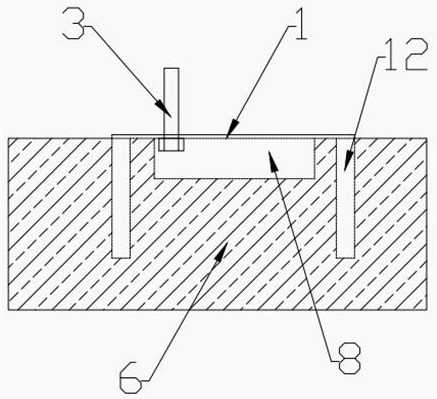

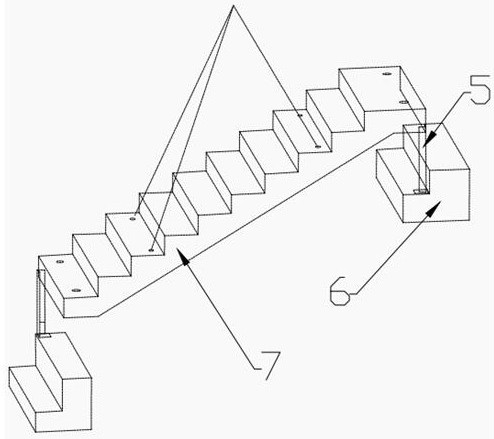

[0022] like Figure 1-Figure 3 As shown, the precise positioning method for prefabricated stairs provided in this embodiment includes the following steps: S1, prefabricating an auxiliary positioning device for stairs in a factory; The lower end of 1 is provided with several vertical protrusions 12 (there are four vertical protrusions in a rectangular distribution), and an adjustment chute 11 is provided on the pre-embedded steel plate 1, and the adjustment chute 11 is a Rectangular through groove or be made up of four strip grooves that are distributed in a rectangle; The positioning support 5 is composed of an angle steel 51 and an angle plate 52 connected to the bottom of the angle steel 51 and placed on the outside of the angle steel 51, and the angle plate 52 can be Detachably fixed on the pre-embedded steel plate 1; the corner plate 52 is pressed on the pre-embedded steel plate 1 through two cross-shaped overlapping movable platens 2, and is arranged at both ends of each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com