Efficient sedimentation tank

A technology of high-efficiency sedimentation tanks and sedimentation tanks, which is applied in the direction of sedimentation separation, feeding/discharging devices of sedimentation tanks, cleaning hollow objects, etc., can solve the problems of serious sedimentation tank sedimentation efficiency, inability to clean pipes, and water disturbance, etc., to achieve Good precipitation effect, easy to clean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further illustrated below in conjunction with the accompanying drawings and specific embodiments. This embodiment is implemented on the premise of the technical solution of the present invention. It should be understood that these embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

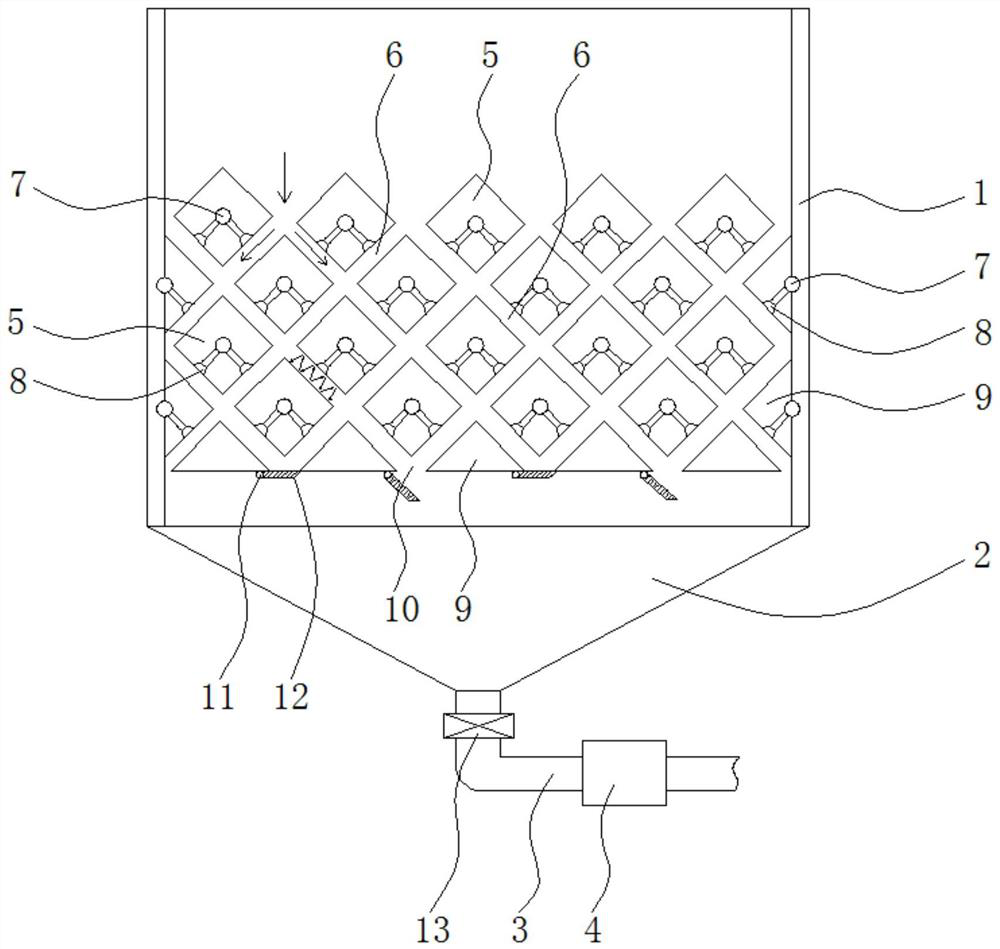

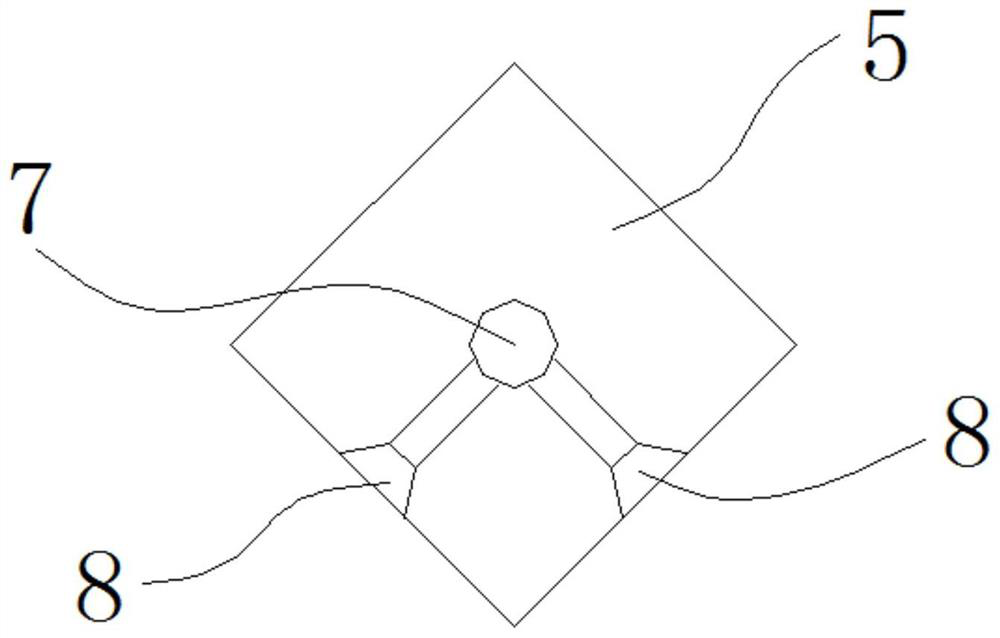

[0017] Such as figure 1 and figure 2 Shown, a kind of efficient settling tank comprises settling tank 1, and the bottom of this settling tank 1 is set as the sedimentation tank 2 of funnel shape, and the bottom of this settling tank 2 is also equipped with suction pipe 3, on the suction pipe 3 A dredge pump 4 is installed; a number of uniformly arranged horizontal pipes 5 are also arranged in the sedimentation tank 1; 5 is set to be installed with a 45° rotation, the four corners are located at the upper, lower, left, and right positions respectively, and the horizontal tubes 5 are ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com