A continuous grading sand screen machine for concrete

A sand screening machine and concrete technology, applied in classification, solid separation, chemical instruments and methods, etc., can solve the problems of low operation efficiency, cost increase, large material loss, etc., and achieve the effect of eliminating the influence of quality factor fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

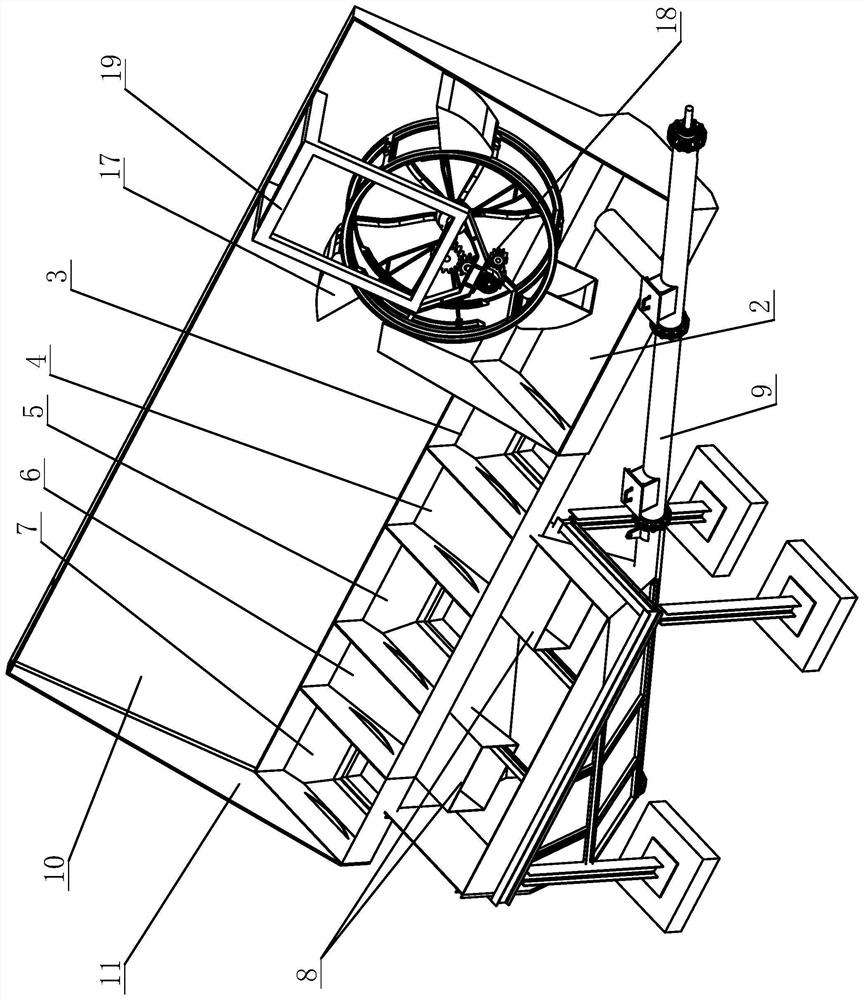

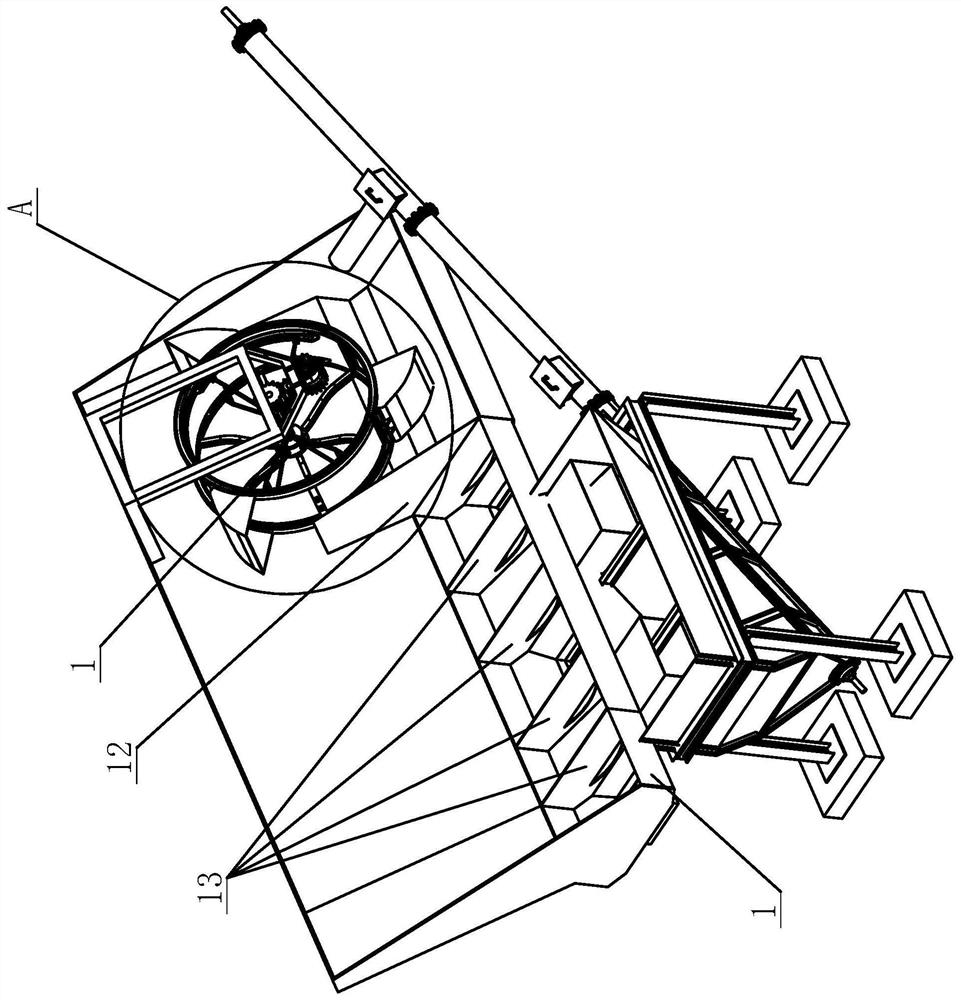

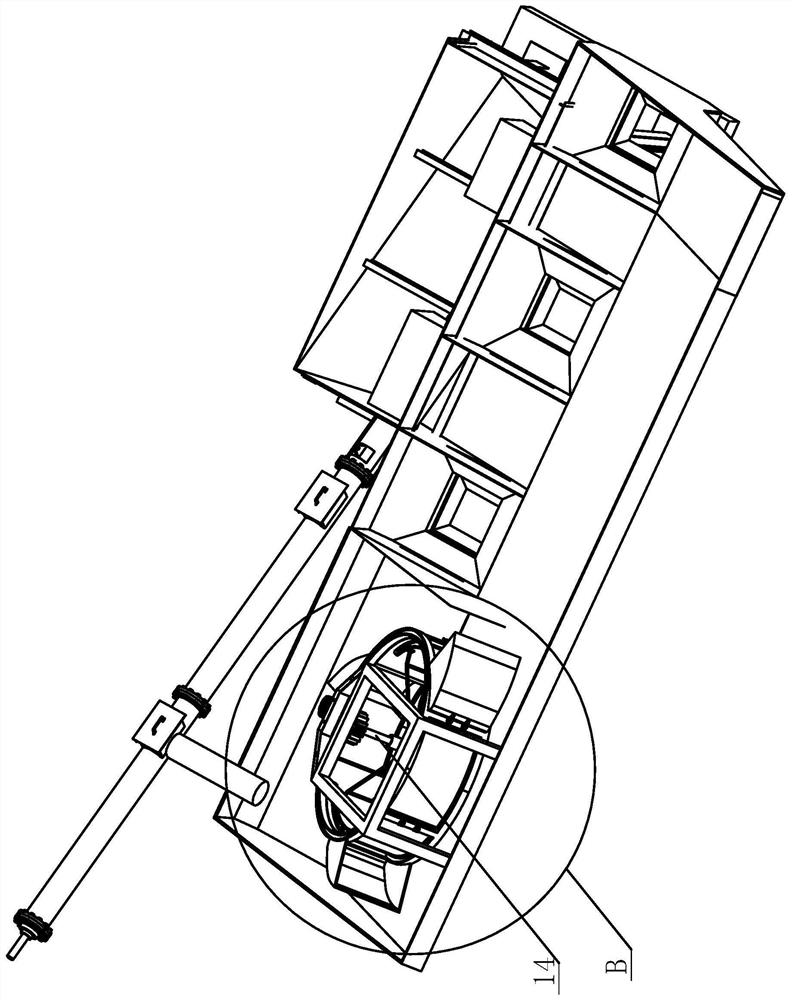

[0030] Embodiment: A kind of continuous grading sand screening machine for concrete

[0031] This example is mainly derived from the research results of our college on the quality of concrete that consumes a lot in civil engineering, and the research results on the proportion of sand used and the control of particle size, based on continuous sand screening and multi-stage Under the design idea of screening, the design plan and idea are explained in detail as follows:

[0032] This sand screening machine includes a hopper arranged at the bottom. The hopper is a rectangular hopper extending straight and has a horizontal bottom surface. A shroud 1 is provided around the hopper. One end is provided with the upper hopper 2, the first drop hopper 3, the first buffer hopper 4, the second drop hopper 5, the second buffer hopper 6, the third drop hopper 7 in turn, the upper hopper 2, the first drop hopper 3, The first buffer hopper 4 , the second drop hopper 5 , the second buffer ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com