Mechanical lock mechanism of integrated linkage coordination valve

A technology for mechanical locks and shutters, applied in non-mechanical transmission-operated locks, aircraft doors, building locks, etc., can solve the problems of mechanical lock fatigue life influence, unstable unlocking action, and large compound load, etc., to achieve easy manufacturing and Maintenance, simple structure, reliable unlocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with specific preferred embodiments, but the protection scope of the present invention is not limited thereby.

[0046] For the convenience of description, the relative positional relationship of each component, such as: the description of up, down, left, right, etc., is described according to the layout direction of the drawings in the specification, and does not limit the structure of this patent.

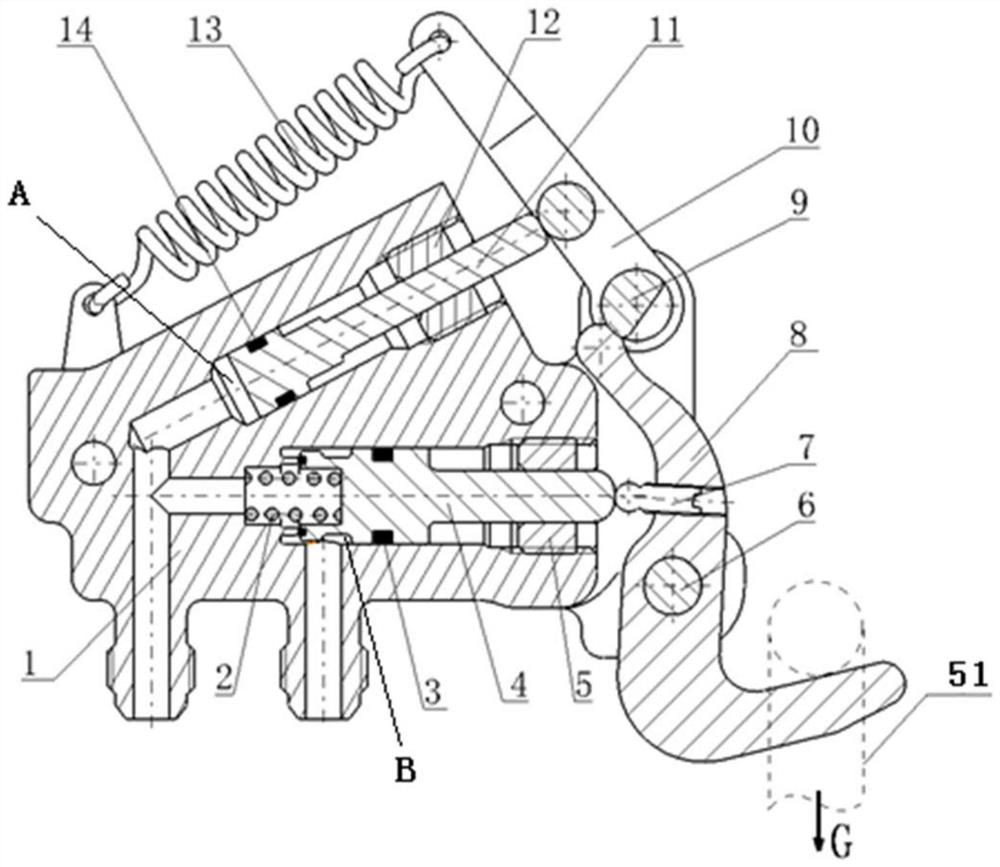

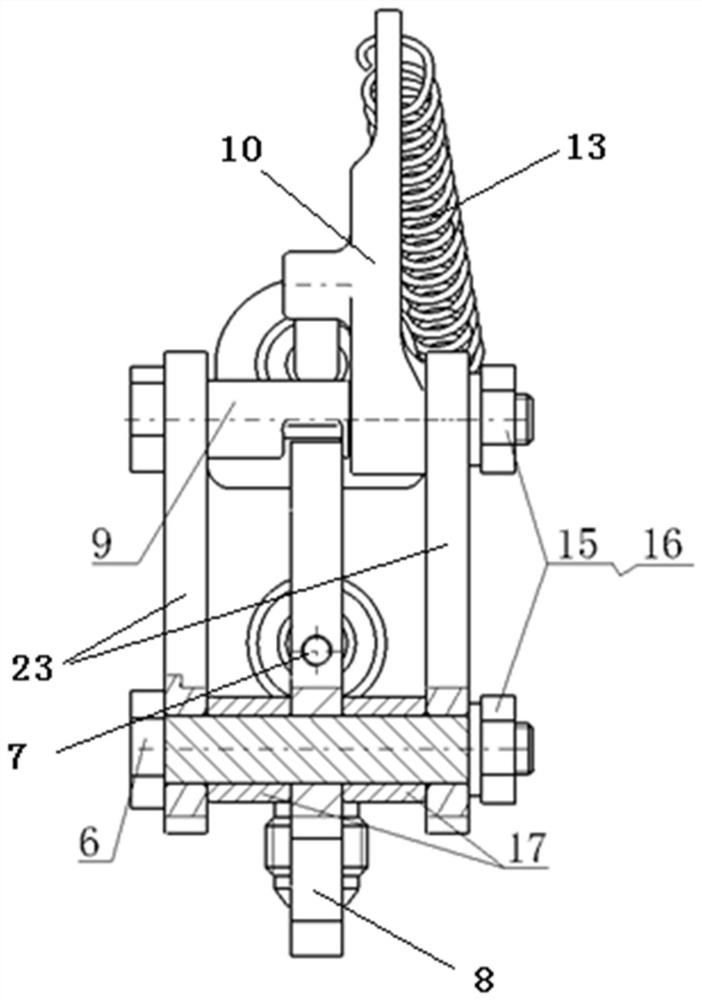

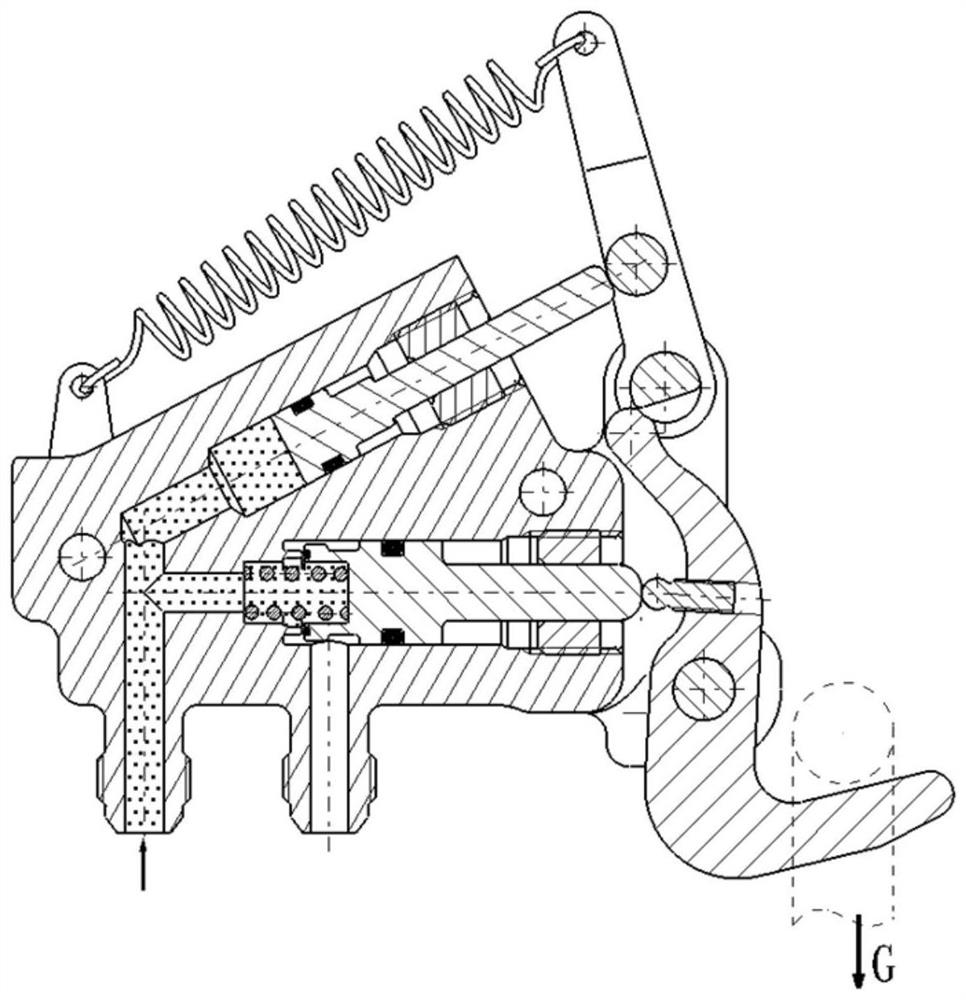

[0047] Such as figure 1 - Figure 18 As shown, the present invention adopts the integrated design technology, and integrates the hydraulically controlled unlocking actuator A and the coordinating valve B into the mechanical lock mechanism. Specifically, an embodiment of the present invention includes a lock housing 1, an unlocking piston rod 11, a coordination valve rod 4, a second guide sleeve 12, a first guide sleeve 5, a lock hook 8, a top post 7, a lock post bolt 9, Rocking arm 10, hinge bolt 6, spa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com