Novel grille panel and mounting method thereof

A grid and panel technology, applied in the field of grids, can solve the problems such as the grid plate is not beautiful enough, the grid plate has process seams, and the decorative effect is affected, and the installation method is convenient and fast, reducing the film coating time and improving the aesthetics. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

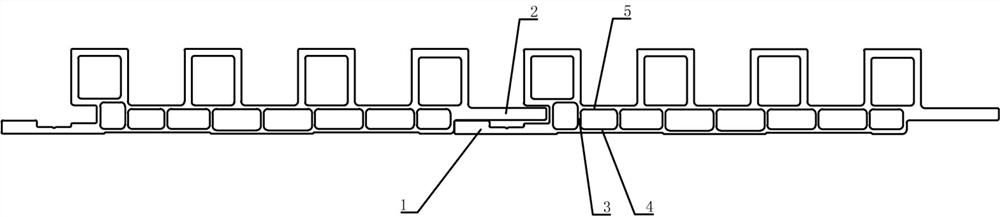

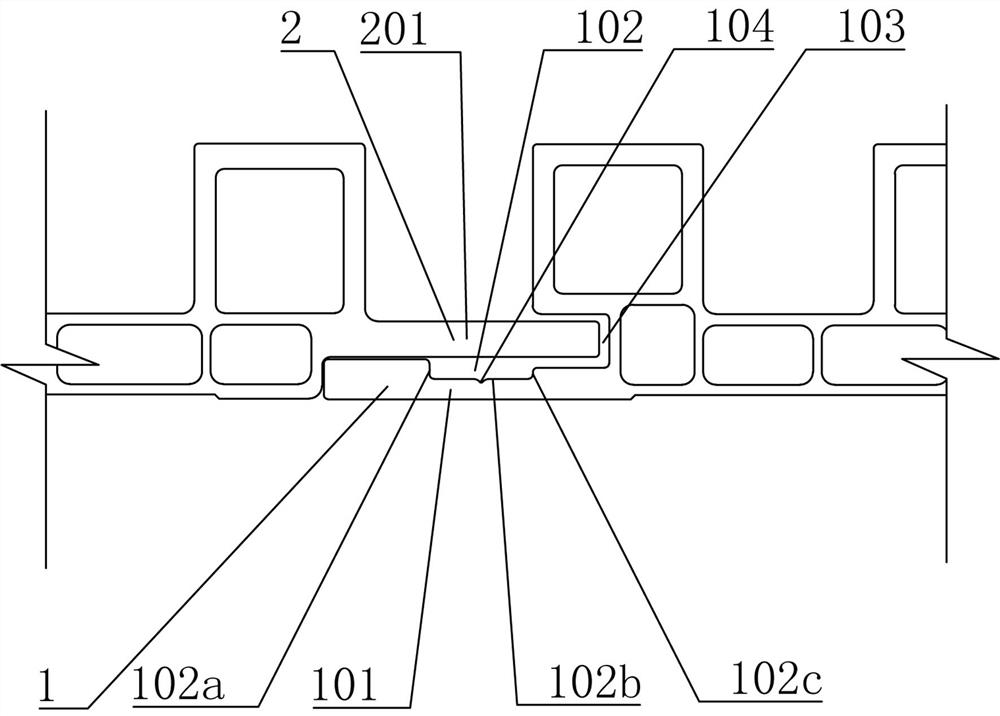

[0026] Example 1: as Figure 1-3 As shown, it is only one embodiment of the present invention, a new type of grille panel, including a grille top panel 5 and a grille bottom panel 4 used to form the grille panel, and a grille top panel 5 and a grille bottom panel arranged at intervals The grid bars 3 between 4, the two ends of the panel are respectively provided with a first clamping part 1 and a second clamping part 2 for connecting the adjacent panels to each other; the first clamping part 1 is provided with a The slot 103 for accommodating the second engaging portion 2 and the limiting portion 101 for limiting the second engaging portion 2 are provided. The second engaging portion 2 is provided with an engaging rod 201 for clearance fit with the slot 103 .

[0027] First, the first clamping portion 1 is provided with a fixing groove 102 for installing screws for fixing the grille panel. To facilitate the installation of the screws, the fixing groove 102 is provided with a ...

Embodiment 2

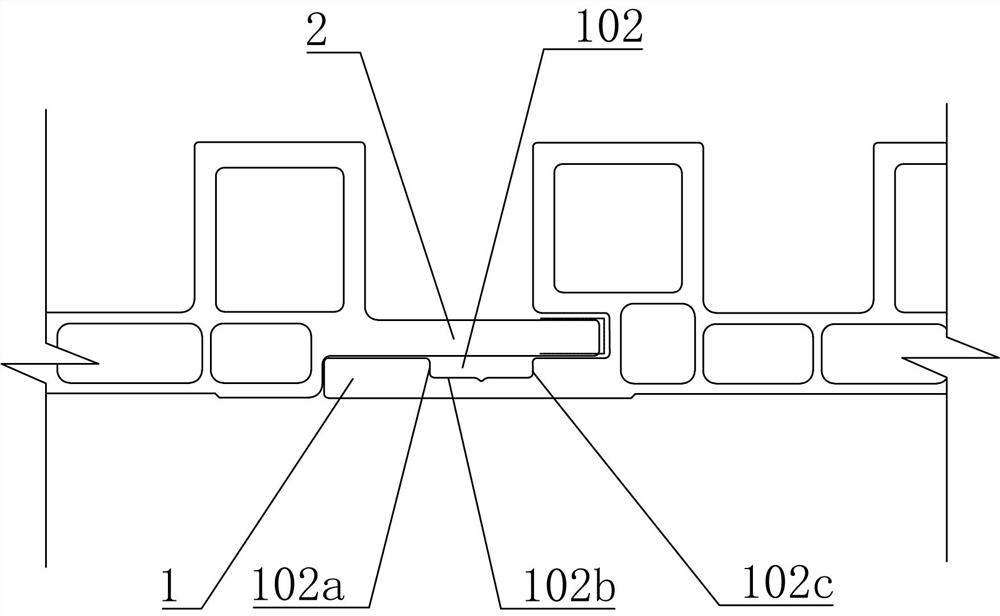

[0032] Embodiment 2: as Figure 4 As shown, it is only one embodiment of the present invention. The difference from the first embodiment is that the height of the clamping rod 201 gradually increases from the outside to the inner, that is to say, the cross section of the clamping rod 201 is no longer a rectangular surface. Instead, it is a trapezoidal surface. Correspondingly, the card slot 103 is not a regular U-shaped slot, and the size of the card slot 103 gradually decreases from the outside to the inside. This arrangement facilitates the insertion of the clamping rod 201 and the clamping slot 103, so that the connection between the grill panels is more firm.

Embodiment 3

[0033] Embodiment 3: The present invention also provides a method for installing a novel grid panel in all the above embodiments, including the following steps:

[0034] S1: Measure the length with a tape measure on the wall, and set the installation position of the grille panel;

[0035] S2: Use glue to fix the side of the grille panel close to the wall panel to the wall;

[0036] S3: Install screws on the side of the grille panel away from the wall panel;

[0037] S4: Insert the clamping rod 201 of the other grid panel into the clamping slot 103 of the grid panel that has been fixed to the wall.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com