Manufacturing mold and method for conductivity probe of conductivity-temperature-depth measuring instrument

A conductivity probe and measuring instrument technology, applied in the field of sensors, can solve the problems of inconsistent pressure resistance, inability to ensure gap sealing, damage to the temperature and salt depth measuring instrument, etc., and achieve uniform thickness in all directions, simple probe structure, and stable performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

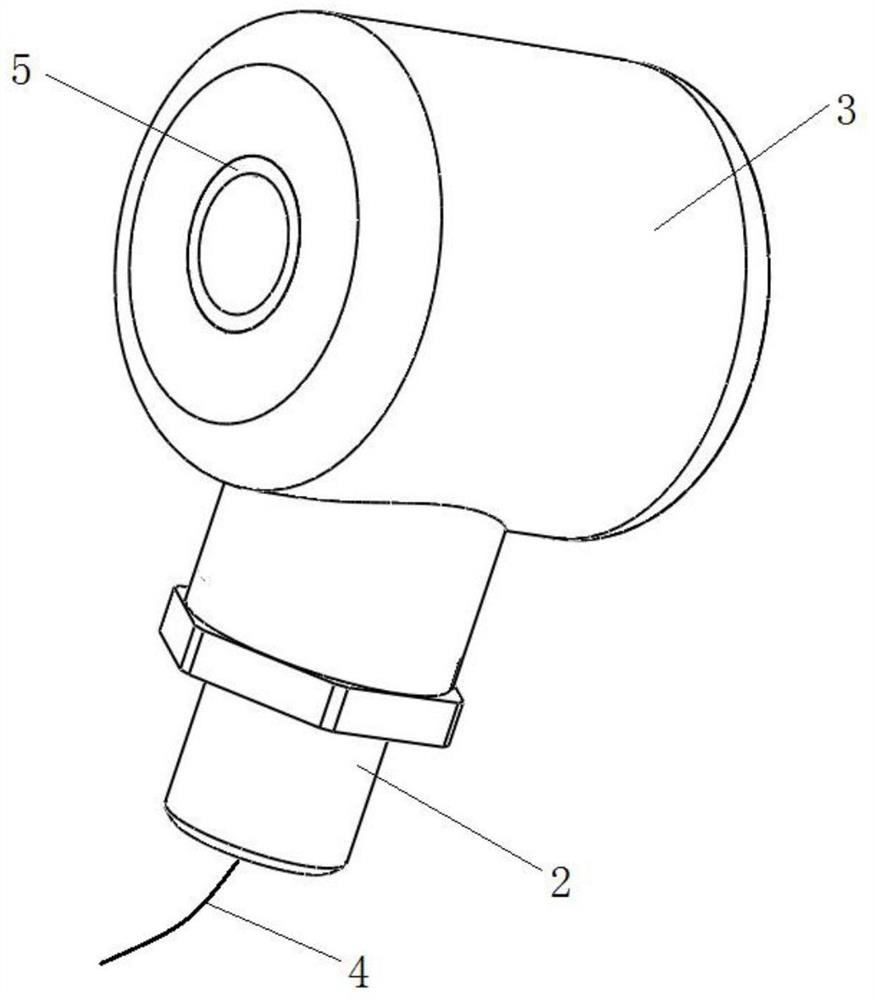

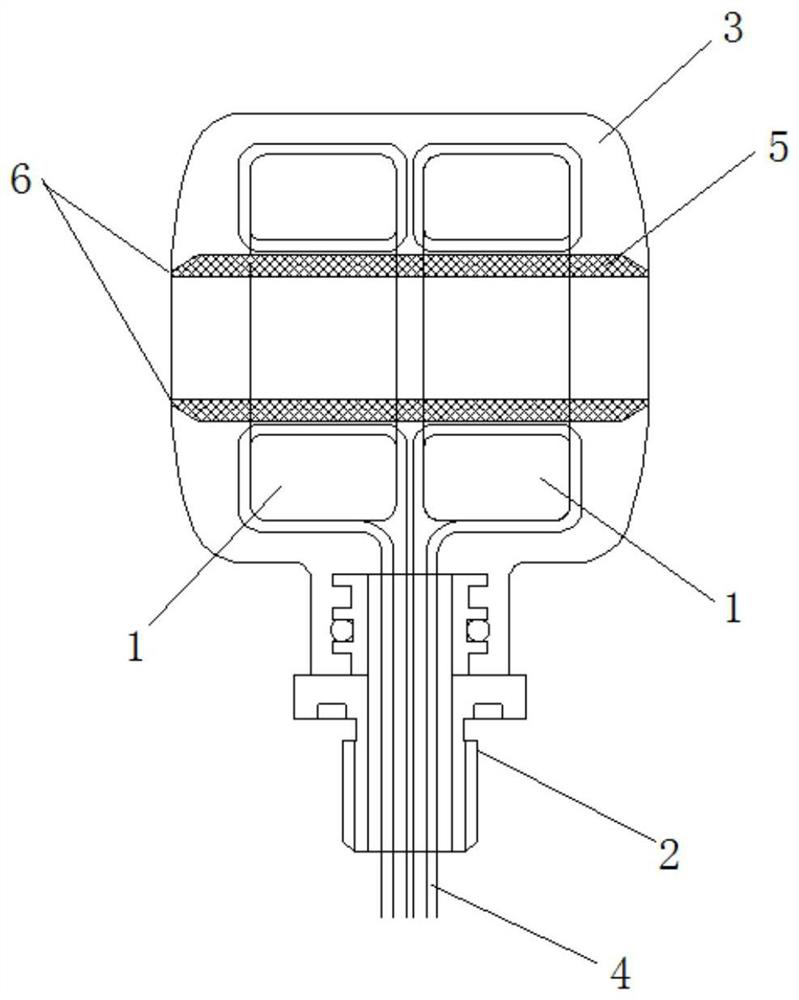

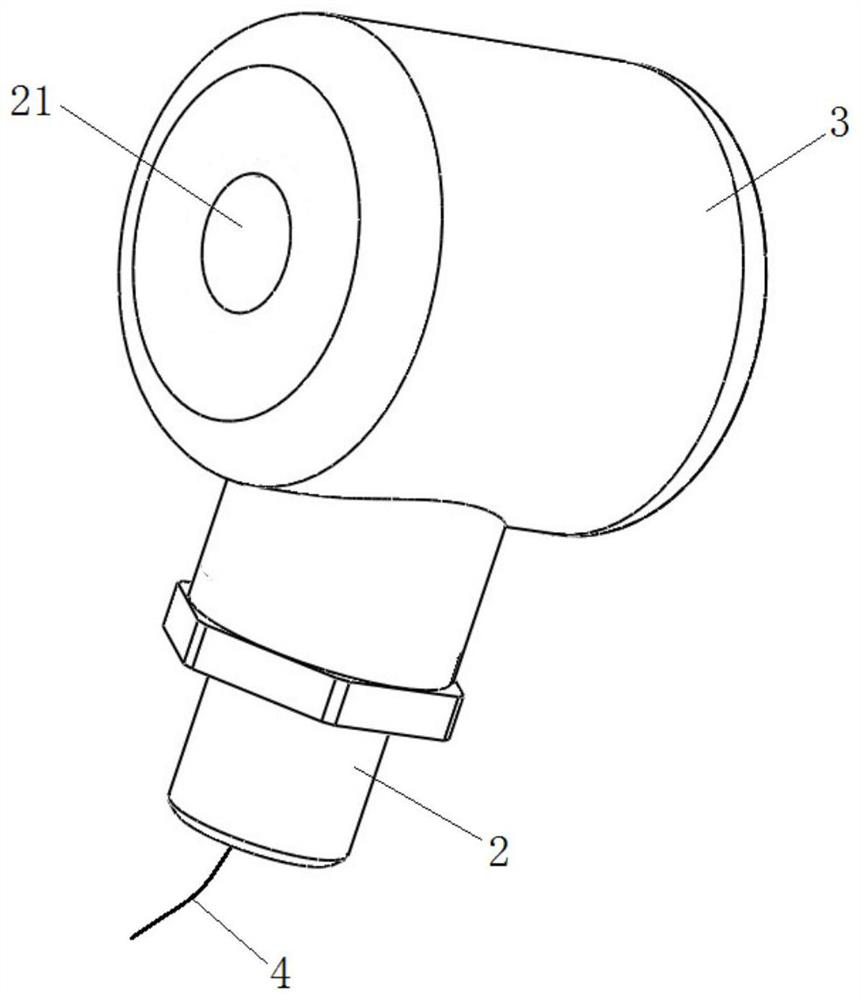

[0033] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0034] The invention provides a mold for making a conductivity probe of a temperature, salt and depth measuring instrument, comprising an upper template 7 and a lower template 8, such as Figure 5 , Image 6 and Figure 7 As shown, both the upper template 7 and the lower template 8 are provided with a primary packaging positioning cavity 9 and a secondary packaging positioning cavity 10 for accommodating the magnetic ring 1 and the base 2, and the primary packaging positioning cavity 9 and the secondary packaging positioning cavity 10 Runners 11 are opened in between, and the primary packaging positioning cavity 9 includes a vertical positioning groove 12 for accommodating the magnetic ring 1 and a horizontal positioning groove 13 for accommodating the base 2, and the vertica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com