A kind of shear lifting agent for solid-free completion fluid workover fluid for oil and gas wells and preparation method thereof

A technology without solid phase and completion fluid, which is applied in the fields of workover fluid additives and oilfield completion fluids, which can solve the problems of poor suspension and sand-carrying of workover fluid, and achieve the effect of preventing sand settling and obstruction accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

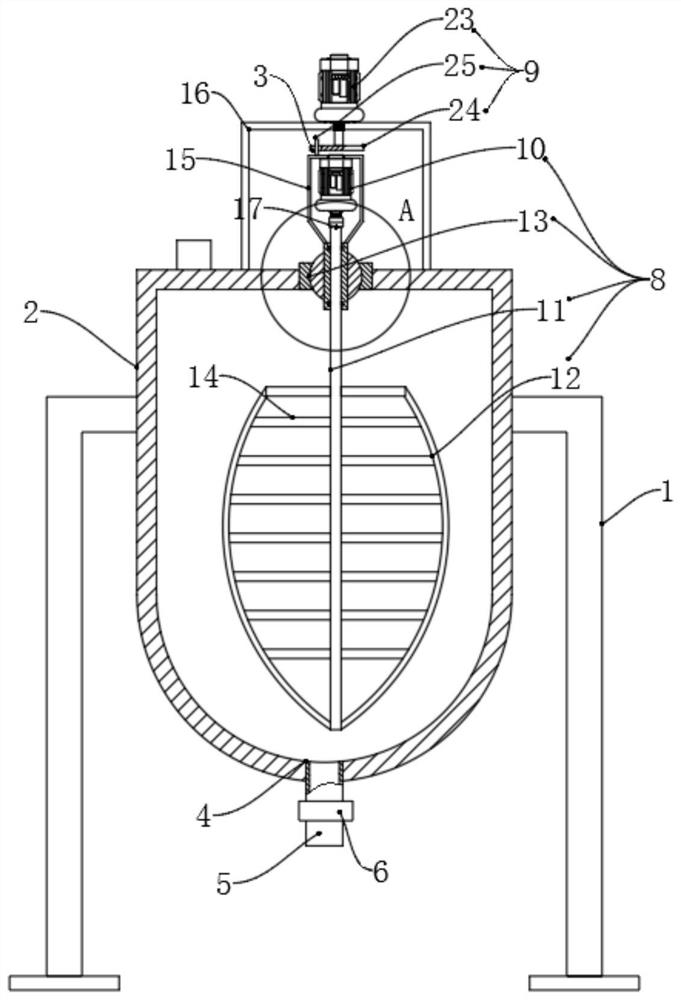

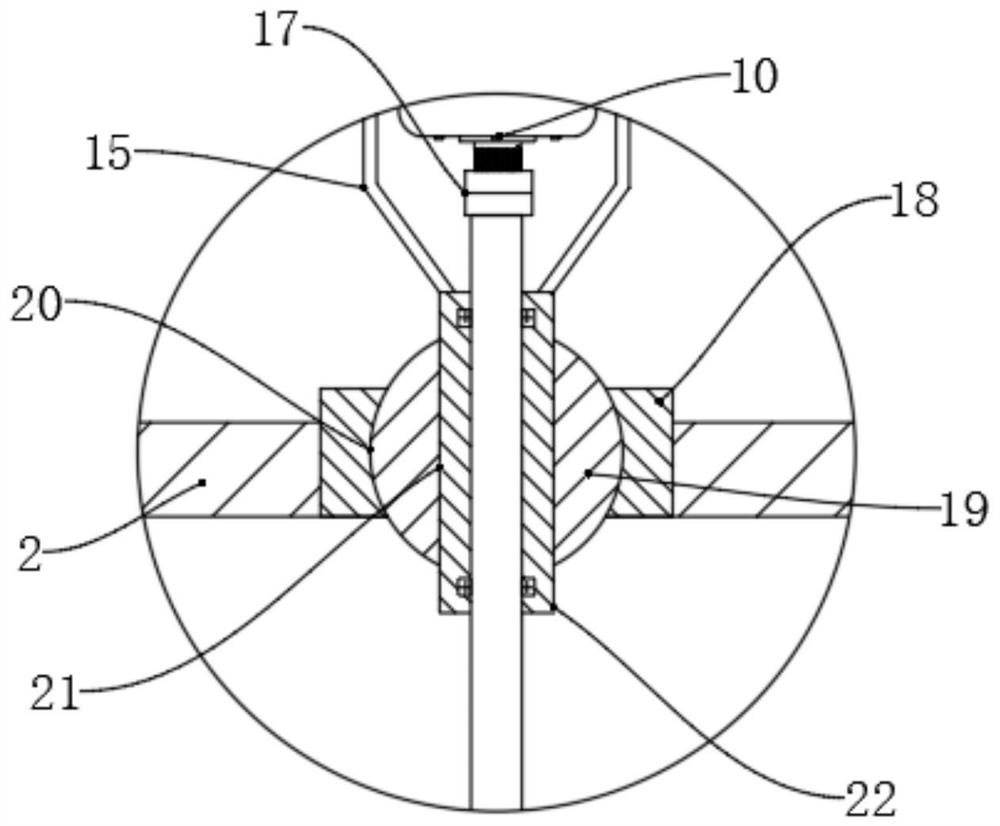

Image

Examples

Embodiment 1

[0042] This embodiment discloses a shear lifting agent for solid-free completion fluid and workover fluid for oil and gas wells. The percentage composition is 8-12% of metal salt; 28-32% of alkalinity regulator; 8-12% of flow pattern regulator; and the balance is water.

[0043] To further define, in this embodiment, the raw materials of each component are composed according to the following weight percentages, 10% of metal salt, 30% of alkalinity regulator, 10% of flow pattern regulator, and 50% of water.

[0044] Among them, the metal salt is aluminum chloride, chromium chloride, manganese chloride, manganous chloride, ferrous chloride, cupric chloride, calcium chloride, ferric chloride, magnesium chloride, manganese nitrate, aluminum nitrate, magnesium nitrate salts of any two different metals.

[0045] It should be further explained that, in actual use, the composition ratio of any two different metals in the metal salt is the same as the molecular mass ratio.

[0046] W...

Embodiment 2

[0072] This embodiment is basically similar to Embodiment 1, the difference is that according to the quality and 100% of the raw materials: 50% of water, 10% of metal salt, 30% of alkalinity regulator, 10% of flow regulator; wherein, metal salt It is composed of aluminum chloride and magnesium nitrate at a ratio of 1:1, the alkalinity regulator is sodium hydroxide, and the flow pattern regulator is polymeric alcohol. In the reaction device, add the formulated amount of water first, then add the formulated amount of metal salt, dissolve and mix evenly; slowly add the formulated amount of alkalinity regulator to ensure that the pH value is maintained at 9; after the reaction is completed, add the flow type Regulator, stirred at a constant speed for 3 hours, with a rotating speed of 500r / min; evaporated to dryness, pulverized to obtain powder.

Embodiment 3

[0074] This embodiment is basically similar to Embodiment 1, the difference is that according to the quality and 100% of the raw materials: 50% of water, 10% of metal salt, 30% of alkalinity regulator, 10% of flow regulator; wherein, metal salt It is composed of magnesium chloride and aluminum chloride at a ratio of 1:1, the alkalinity regulator is sodium hydroxide, and the flow pattern regulator is polymeric alcohol. In the reaction device, add the formulated amount of water first, then add the formulated amount of metal salt, dissolve and mix evenly; slowly add the formulated amount of alkalinity regulator to ensure that the pH value is maintained at 9.5; after the reaction is completed, add the flow type Regulator, stirred at a constant speed for 3 hours, with a rotating speed of 500r / min; evaporated to dryness, pulverized to obtain powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com