A precise horizontal marking device for construction

A construction and marking technology, applied in construction, building structure, processing of building materials, etc., can solve the problems affecting the stability of the marking pen and equipment instability, and achieve automatic fixing and unlocking of the turntable, stable device, simple and convenient. Unlock the effect of the turntable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

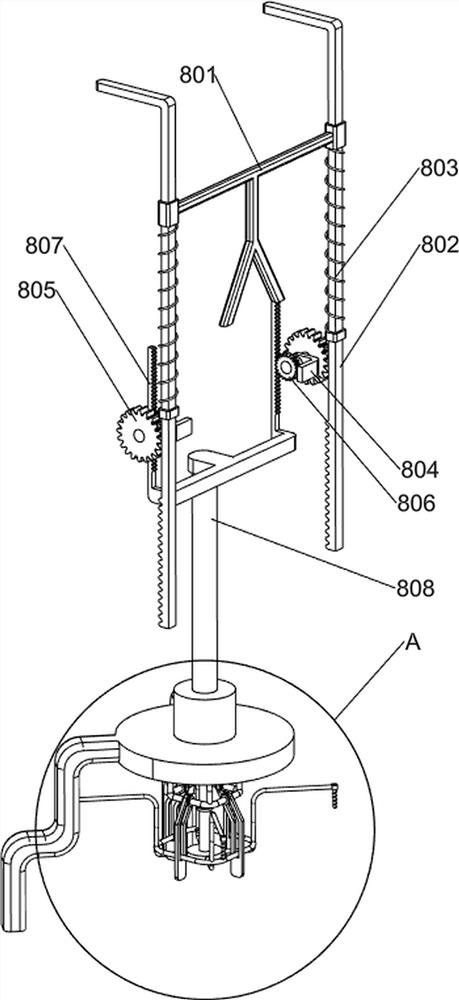

[0030] A precise horizontal marking device for construction, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Image 6 As shown, it includes a base 1, a support frame 2, an adjustment assembly 3, a marking assembly 4 and a drive assembly 5. The support frame 2 is connected in the middle of the upper part of the base 1, and an adjustment assembly 3 is provided on the rear side of the support frame 2. The adjustment assembly 3 A marking assembly 4 is provided on the upper part, and a driving assembly 5 is provided between the adjustment assembly 3 and the upper part of the support frame 2 .

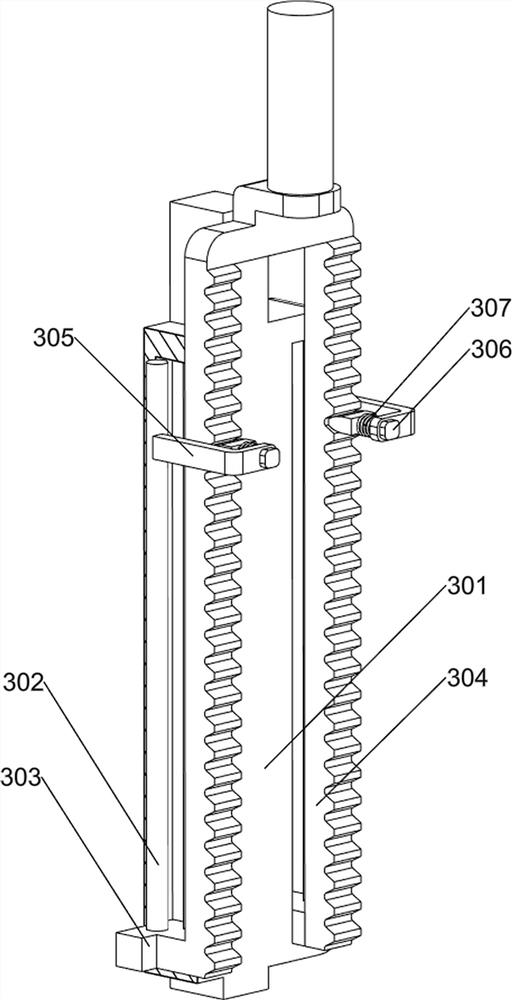

[0031] The adjustment assembly 3 includes a first support groove block 301, a first guide rod 302, a first slider 303, a first rack 304, a first support block 305, a first clamping block 306 and a first spring 307. The support frame 2 The first support groove block 301 is connected to the inner rear side, and the first guide rod 302 is connected symmetrically to the...

Embodiment 2

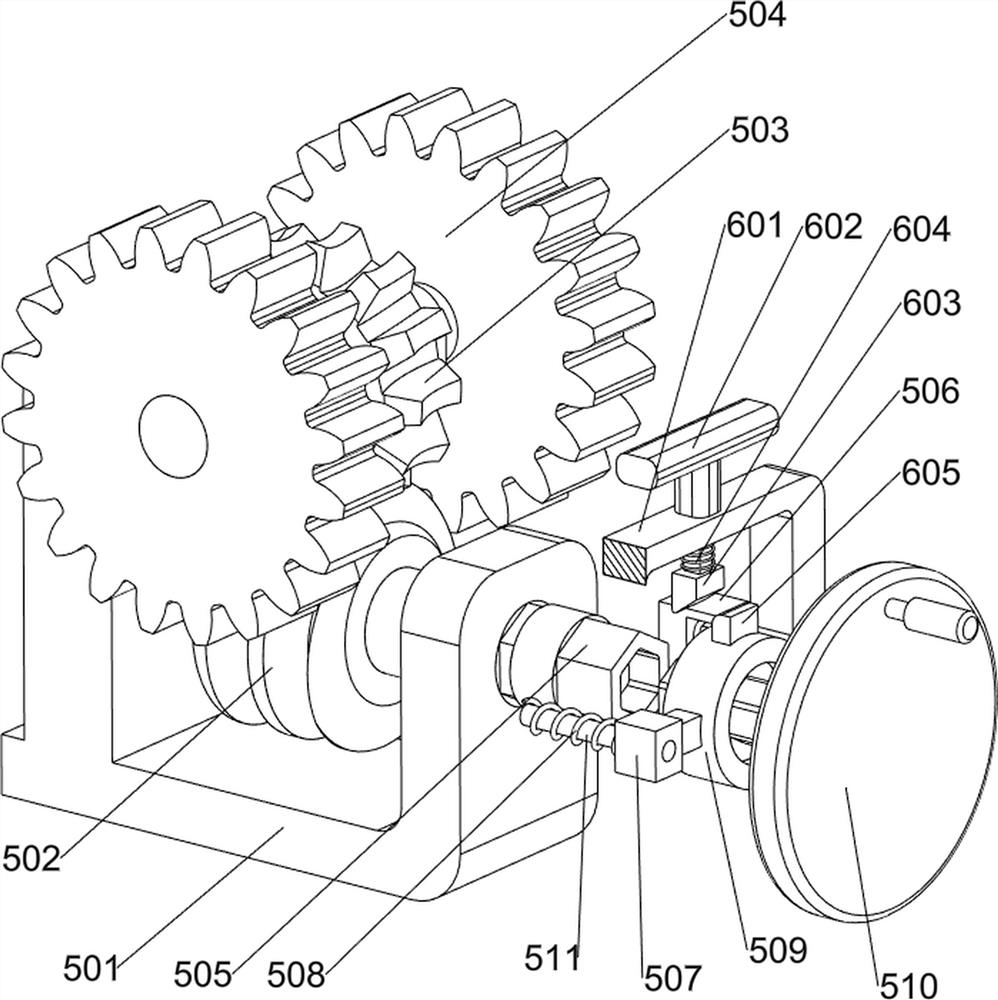

[0036] On the basis of Example 1, such as Image 6 , Figure 7 , Figure 8 with Figure 9 As shown, a locking assembly 6 is also included, and the locking assembly 6 includes a support rod 601, a pull rod 602, a second block 603, a sixth spring 604 and a second block 605, and the upper front side of the third support groove block 506 A support rod 601 is connected between them, a pull rod 602 is slidingly connected in the middle of the upper part of the support rod 601, a second stopper 603 is connected to the lower side of the pull rod 602, and a sixth spring 604 is connected between the second stopper 603 and the support rod 601. The sixth spring 604 is sleeved on the pull rod 602 , and the upper part of the bearing 509 is connected with a second clamping block 605 , and the second clamping block 605 cooperates with the second blocking block 603 .

[0037] The bearing 509 moves backward, drives the second block 605 to move backward, pushes the second block 603 to move upw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com