Electronic device processing system

A processing system and electronic device technology, applied in metal processing, etc., can solve problems affecting work efficiency, inability to install heat-conducting silicone pads, long processing time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

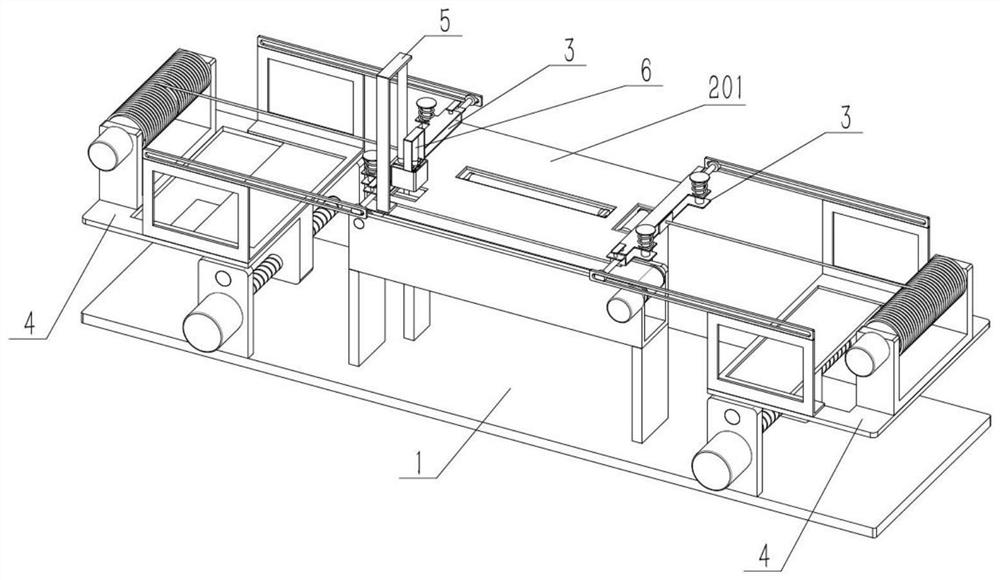

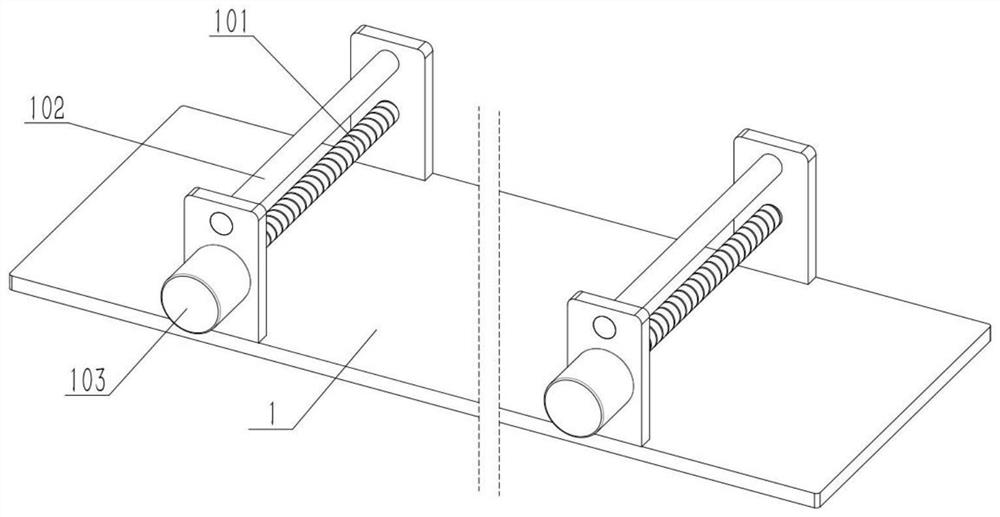

[0029] As shown in the figure, an electronic device processing system includes a bracket I5, an electric push rod II501, a cutter 502, a bracket II503, an electric push rod III6 and a push plate 603, and the upper end of the bracket I5 is fixedly connected to the electric push rod II501, The cutter 502 is fixedly connected to the movable end below the electric push rod II 501, the upper end of the cutter 502 is fixed to the bracket II 503, the electric push rod III6 is fixed to the bracket II 503, the push plate 603 is arranged under the electric push rod III 6, and the electric push rod III The rod III6 is used to drive the push plate 603 up and down, and the push plate 603 is located inside the cutter 502 . Set the silicone heat conduction pad used for electronic devices under the cutter 502, start the electric push rod II 501, the electric push rod II 501 and the electric cutter 502 descend, and the cutter 502 cuts off a piece of the silicone heat conduction pad. The cutter ...

specific Embodiment approach 2

[0031] As shown in the figure, the electronic device processing system also includes a mounting plate 601 and a vertical rod II 602. The movable end of the electric push rod III6 is fixed to the mounting plate 601, and the mounting plate 601 is slidably connected to two vertical rods II 602 and a push plate 603. It is fixedly connected to the lower ends of the two vertical rods II602, and the upper ends of the two vertical rods II602 are fixedly connected to the limit piece. A compression spring, the two ends of the compression spring are in contact with the mounting plate 601 and the push plate 603 respectively. Use the compression spring to make the force generated by the push plate 603 when pressing the silicone heat conduction pad on the electronic device change from small to large, and simulate pressing to avoid the electronic device from being crushed, so that the precision required for the installation of the silicone heat conduction pad is reduced, and excessive pressur...

specific Embodiment approach 3

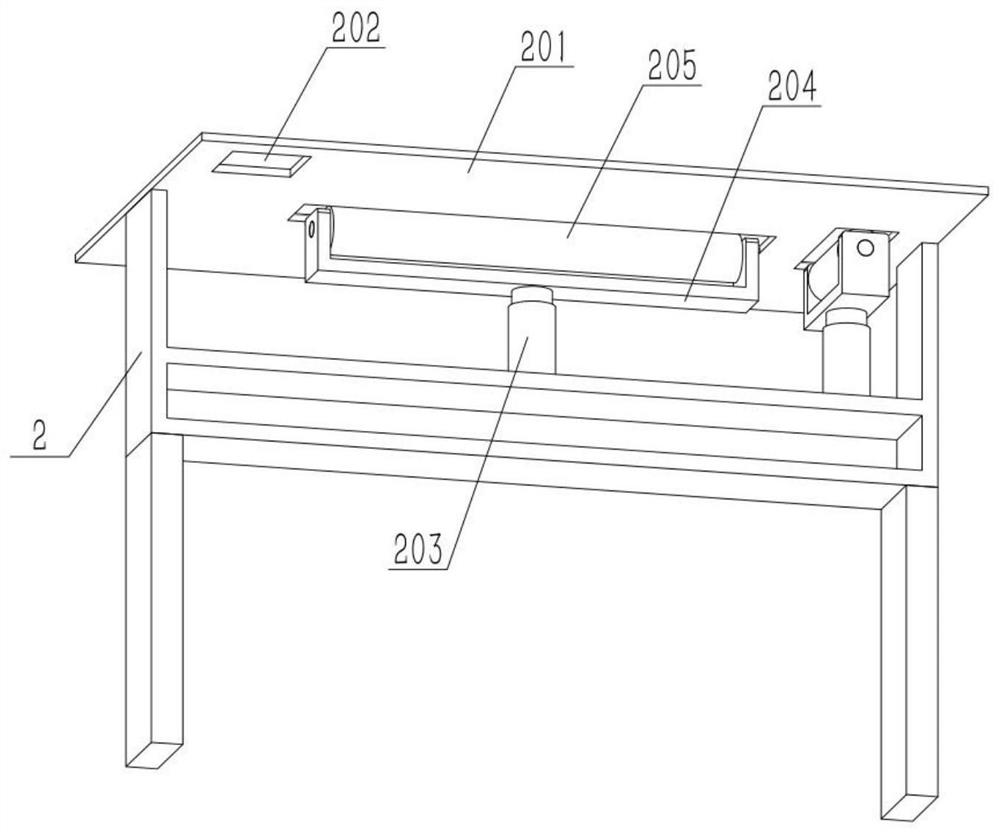

[0033] As shown in the figure, the electronic device processing system also includes a table support 2 , a desktop 201 and a cutout 202 , the upper end of the table support 2 is fixed to the desktop 201 , and the left rear corner of the desktop 201 is provided with a cutout 202 . Place the silicone heat conduction pad on the desktop 201, and the cutout 202 is used to allow the cutter 502 to pass through, and then support the silicone pad through the desktop 201. When the cutter 502 cuts the silicone pad through the cutout 202, the cut part of the silicone pad can be better. Good stretching is conducive to extrusion into the cutter 502, and the lower edge of the cutter 502 is sharp.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com