Connecting structure of motor and wind wheel and tower fan comprising same

A connection structure and wind wheel technology, which is applied to parts of pumping devices for elastic fluids, mechanical equipment, machines/engines, etc., can solve problems such as difficult assembly of wind wheels and motor output shafts, and achieve fast and convenient assembly. The effect of reducing the size of the whole machine and shortening the installation stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

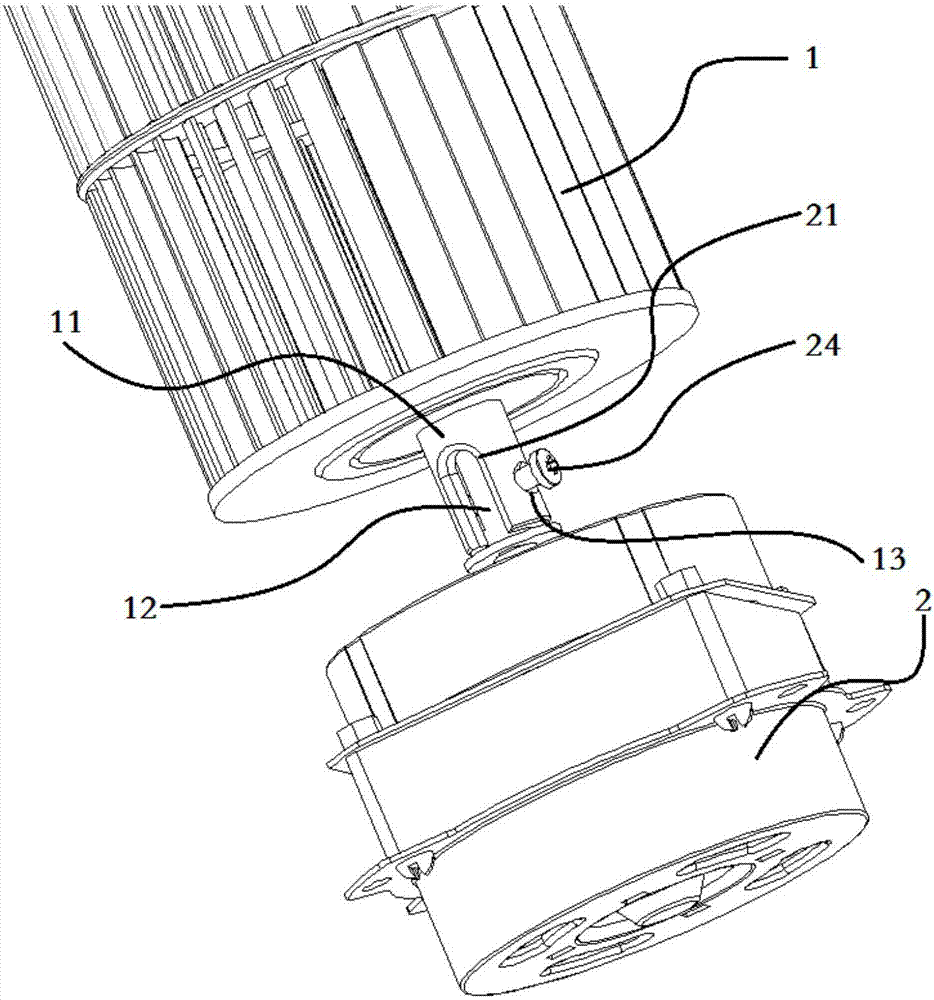

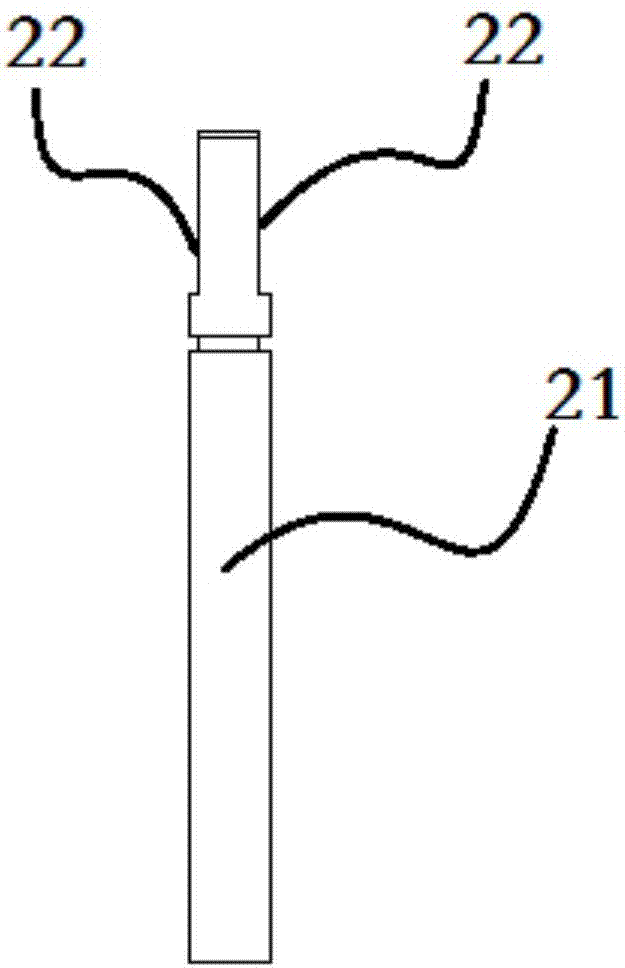

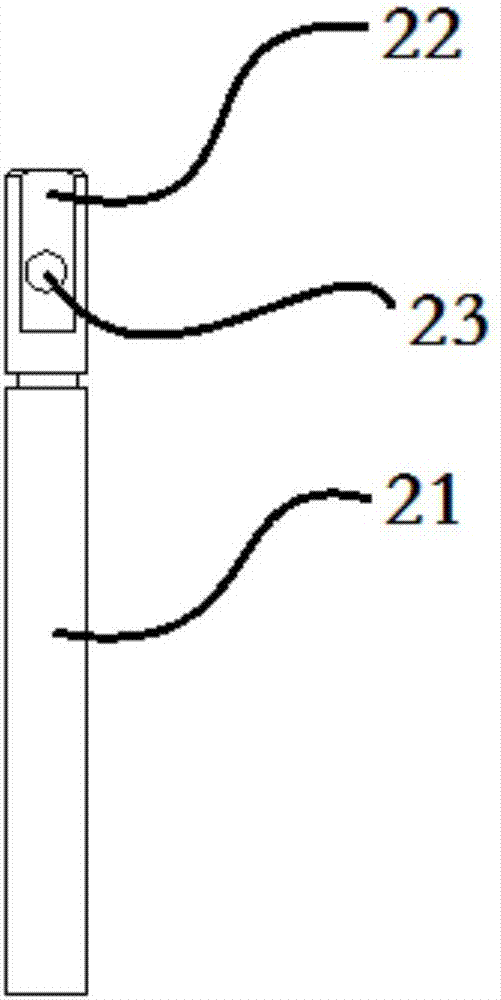

[0036] Such as Figure 1-3As shown, the connection structure between the motor and the wind wheel provided by this embodiment includes a rotating shaft 21 and a connecting piece 11 for transmission, the rotating shaft 21 is suitable for connecting with the motor 2, the connecting piece 11 is suitable for connecting with the wind wheel 1, and The side wall of the connector 11 is molded with a notch 12 extending radially into the interior of the connector 11 and passing through the end wall on one side of the rotating shaft 21 in the axial direction. The 12 places radially move in or out of the connecting piece 11, and the setting of the gap 12 on the connecting piece 11 makes the installation of the wind wheel 1 not affected by the size of the axial installation space during the assembly process of the motor 2 and the wind wheel 1. There is no need to extend into the installation space obliquely from top to bottom, but can be sleeved on the rotating shaft 21 through the connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com