Circuit breaker arc extinguishing system for shrinking narrow slit type double-circulation airflow

A double-cycle, circuit breaker technology, applied in the direction of circuit breaker parts, circuits, electrical components, etc., can solve the problems of arc re-breakdown, etc., and achieve the effect of increasing arc extinguishing speed, reducing re-breakdown, and facilitating arc extinguishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

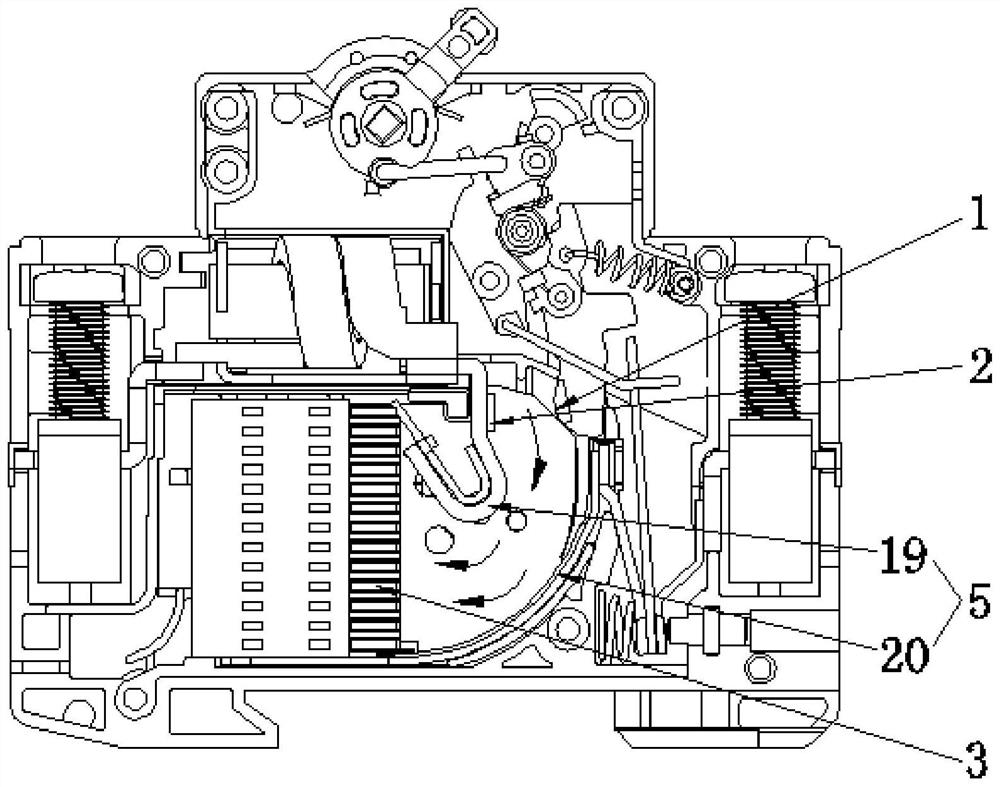

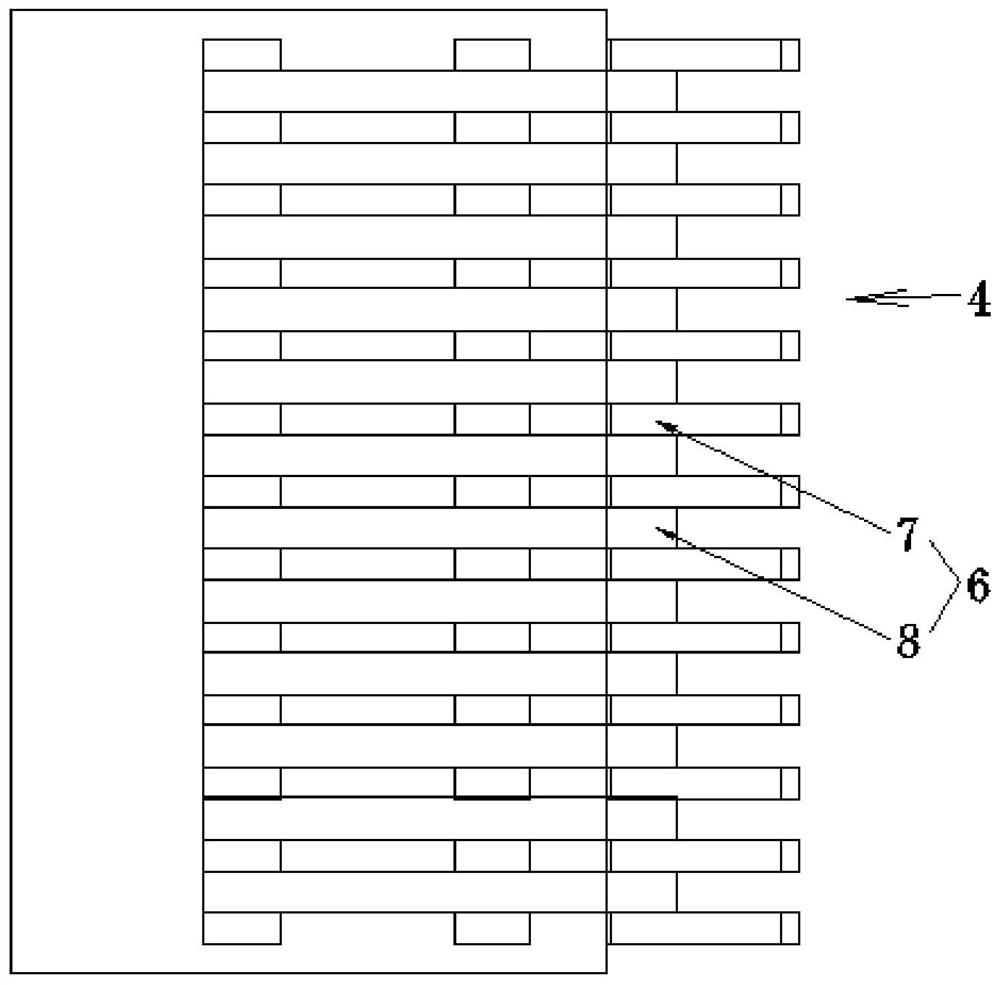

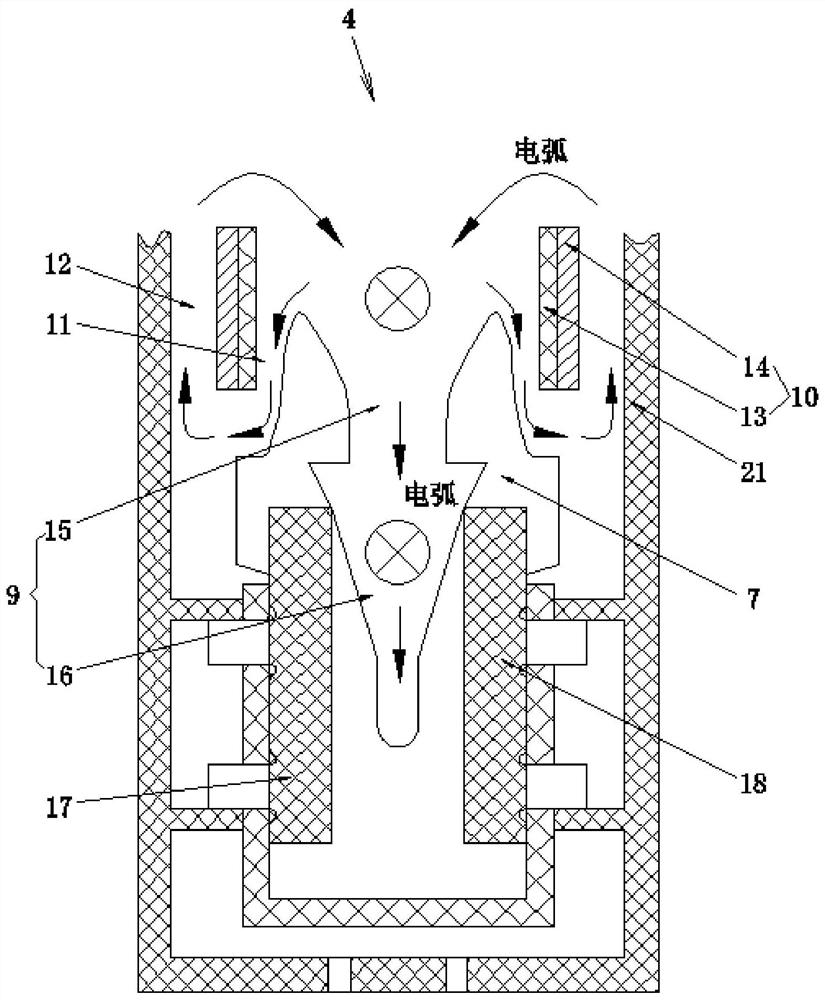

[0028] like Figures 1 to 3 Shown is an embodiment of an arc extinguishing system for a circuit breaker with a shrinking slit type double-circulation air flow of the present invention, including a moving contact 1, a static contact 2, an arc extinguishing chamber 3 and a 4, the arc extinguishing chamber 3 is provided with an arc extinguishing assembly 6, and the arc extinguishing assembly 6 includes a set of arc extinguishing grids 7 arranged at intervals and two adjacent arc extinguishing grids The gas-producing interlayer 8 between the sheets 7 is provided with an opening groove 9 on the arc extinguishing grid sheet 7 near the front end of the arc exting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com