Sugarcane harvester and sugarcane root cutting device thereof

A harvester and sugarcane technology, applied in the field of sugarcane harvesters, can solve the problems of excessive blade wear, poor quality of cutting roots, and high power consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

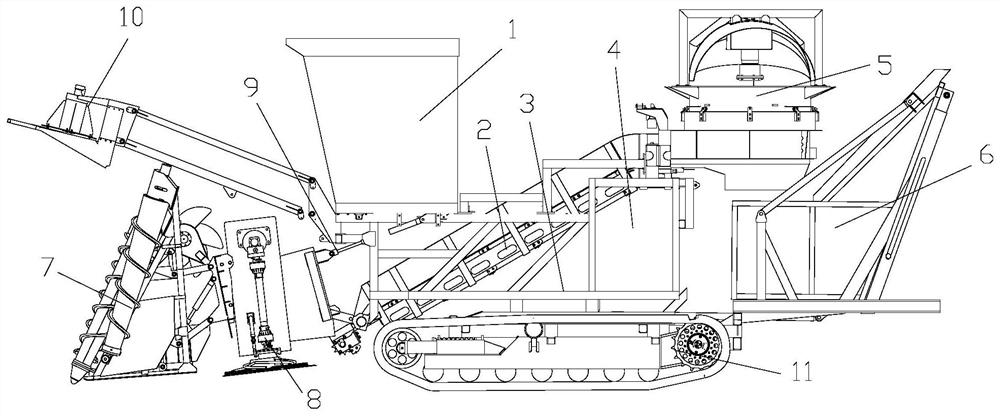

[0054] see figure 1 , figure 1 It is a structural schematic diagram of a sugarcane harvester according to an embodiment of the present invention. The sugarcane harvester of the present invention comprises a frame 3 and a sugarcane root cutting device 8 installed at the front end of the frame 3, the frame 3 is installed on the crawler chassis 11, and the driver's cab 1 is installed on the frame 3, The conveying device 2 and the engine 4 are fixed on the frame 3, and the conveying device 2 is used to convey the cut sugarcane; the miscellaneous fan 5 is fixed on the frame 3, and is used to suck impurities such as broken leaves out of the sugarcane; the collecting hopper 6 is fixed on the frame 3. It is used to collect the harvested sugar cane and unload it. During work, the sugar-free tip of the sugarcane top is cut off earlie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com