A double-shaft water turbine device with s-shaped blade composite membrane blade

A composite membrane and water turbine technology, applied in mechanical equipment, hydroelectric power generation, engine components, etc., can solve the problems of low efficiency and low proportion of windward surface, and achieve the effect of reducing hysteresis effect, prolonging life, and high energy utilization coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is described in further detail below in conjunction with accompanying drawing:

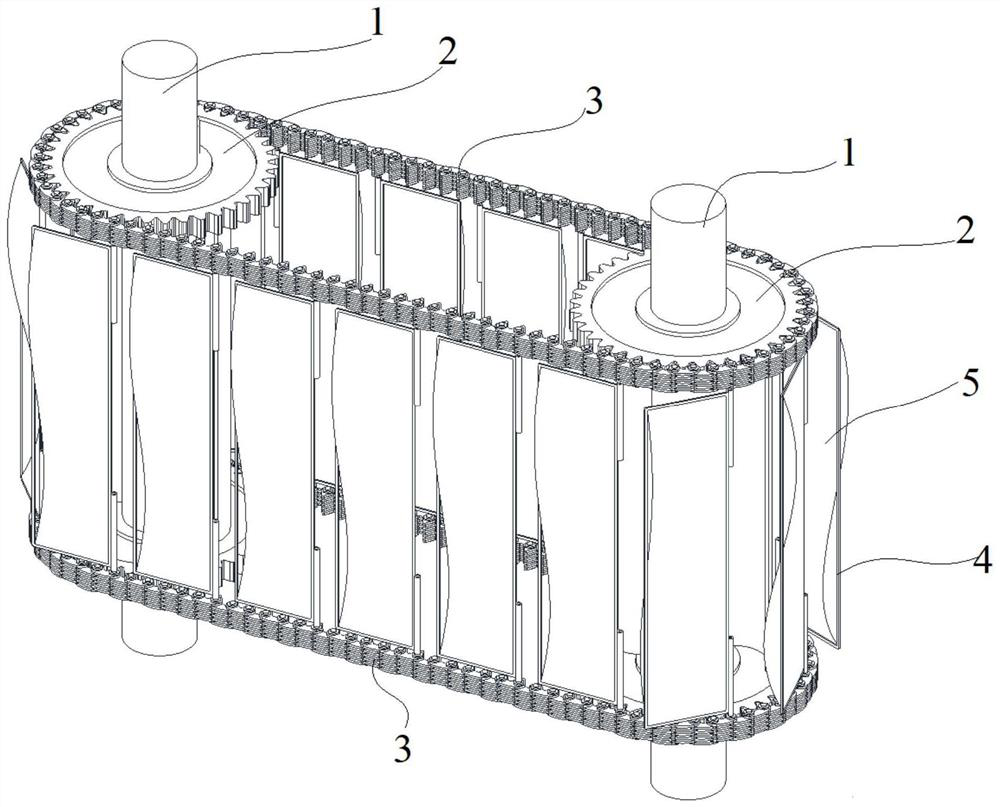

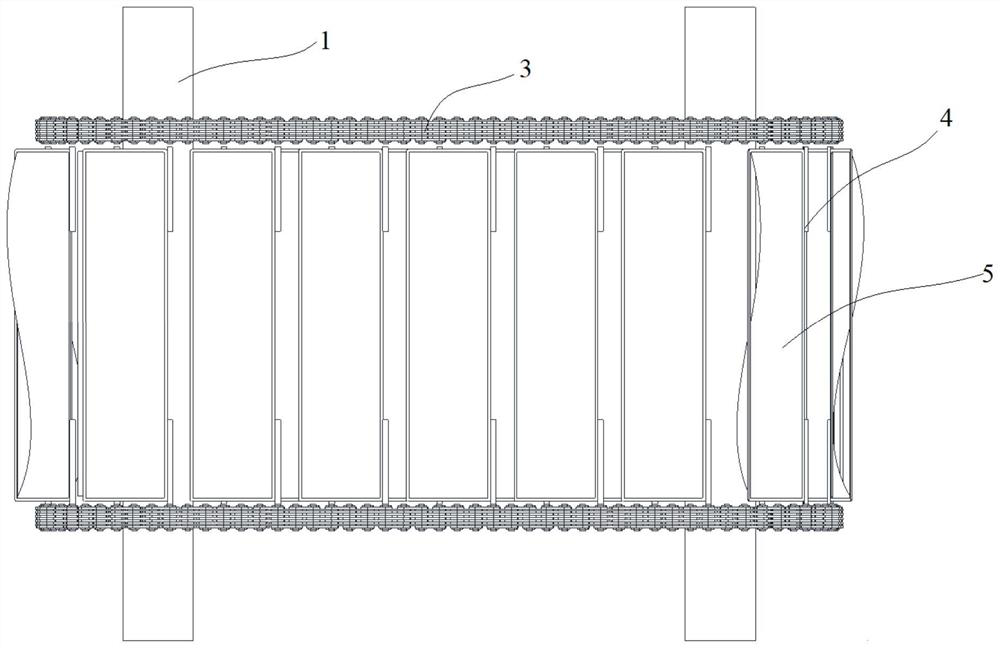

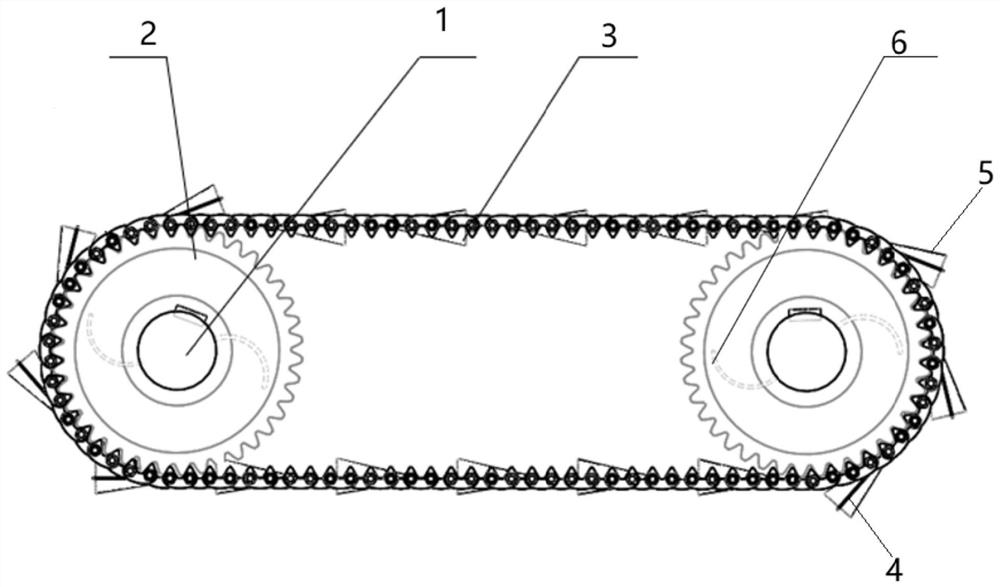

[0028] Such as Figure 1 to Figure 3 As shown, an S-blade composite membrane blade biaxial water turbine device includes two parallel transmission shafts 1, and each transmission shaft 1 is provided with two parallel transmission wheels 2, wherein the two transmission wheels The rotation planes are coplanar, and the rotation planes of the other two transmission wheels are coplanar, that is, two transmission wheels 2 form a group of coplanar transmission wheel groups, and the coplanar transmission wheel groups are connected by a transmission belt 3; The transmission wheels are connected by a transmission belt 3, and a plurality of rectangular blade supports 4 are fixed in an array between the two transmission belts 3, and one side of the rectangular blade support 4 is fixed between the two transmission belts 3 through a fixed shaft, and on the rectangular blade support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com