Reversing valve structure of hydraulic breaking hammer

A technology of hydraulic breaker and reversing valve, which is applied in the direction of fluid pressure actuation device, fluid pressure actuation system components, servo motor components, etc., and can solve problems such as mid-cylinder cavitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

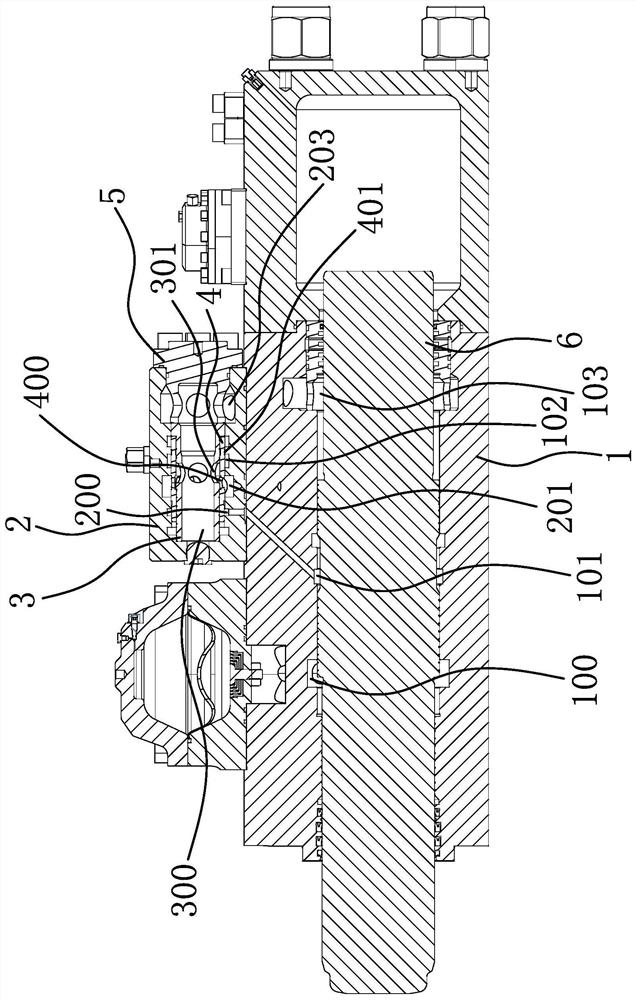

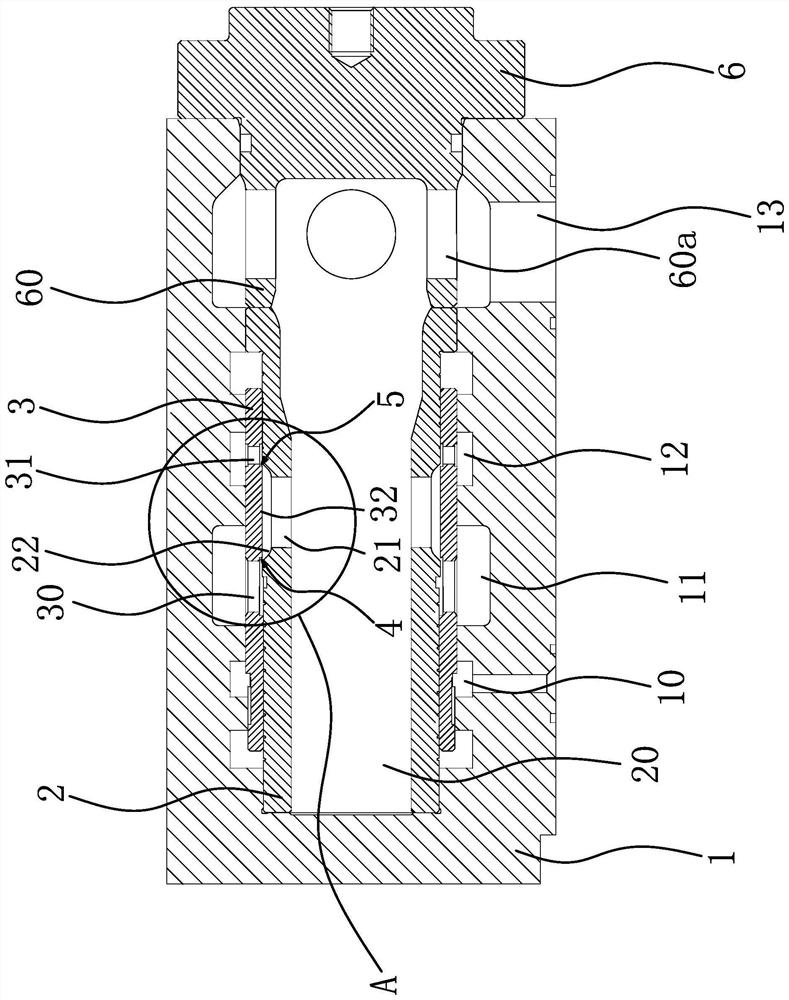

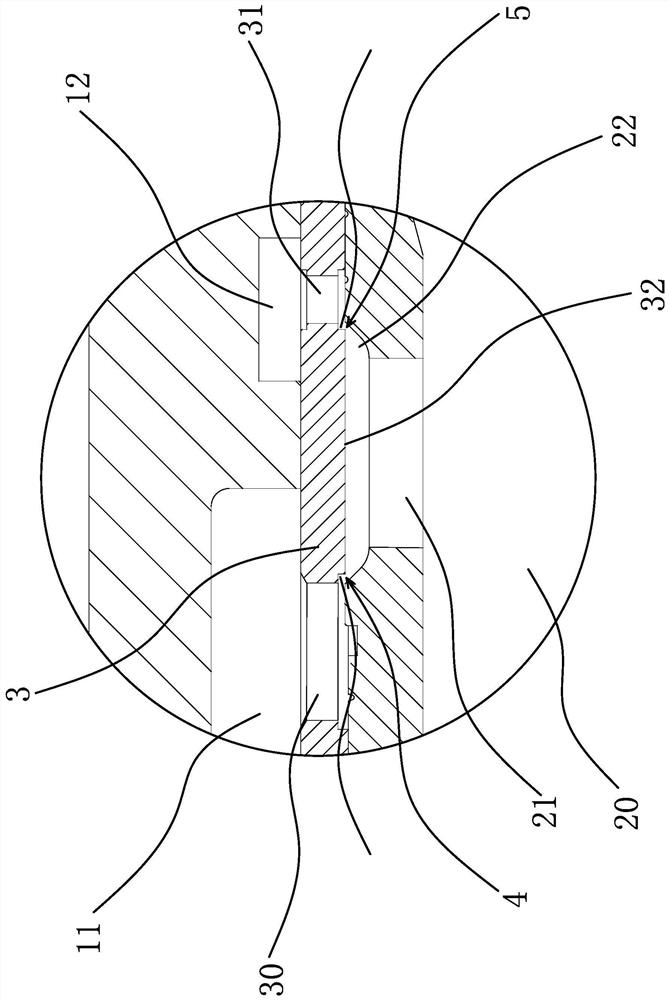

[0029] Such as figure 2 and image 3 As shown, the reversing valve structure of the hydraulic breaker includes a valve body 1, a valve core 2 arranged in the valve body 1, and a reversing valve 3 slidingly arranged between the valve body 1 and the valve core 2. The valve body 1 A reversing chamber 10, a high-pressure chamber 11 and a low-pressure chamber 12 are provided along the inner peripheral surface of the valve core. The valve core 2 has a high-low pressure switching chamber 20, and the middle part of the valve core 2 is provided with an oil hole 21 communicating with the high-low pressure switching chamber 20. , the reversing valve 3 has the oil hole 2 30 that can communicate with the high pressure chamber 11 and the oil hole 1 21, and the oil hole 3 31 that can communicate with the low pressure chamber 12 and the oil hole 1 21, and the inner peripheral surface of the reversing valve 3 is located at the oil hole 2 The position between 30 and oil hole 3 31 has a blocki...

Embodiment 2

[0034] The content of this embodiment is basically the same as that of the above-mentioned embodiment 1, the difference is that in this embodiment, an annular groove 22 is provided on the outer peripheral surface of the valve core 2, and an oil hole 21 is provided on the bottom surface of the groove 22. When the plugging part 32 moves to be opposite to the oil hole 1 21, the oil passage 1 4 communicates with the high-pressure chamber 11 and the groove 22, and the oil passage 2 5 communicates with the low-pressure chamber 12 and the groove 22, and the groove 22 is along the spool 2. The width in the axial direction is greater than the width of the blocking portion 32 in the axial direction of the valve core 2 .

Embodiment 3

[0036] The content of this embodiment is basically the same as that of the above-mentioned embodiment 1. The difference is that in this embodiment, the outer wall of the valve core 2 is provided with a through hole 1 and a through hole 2 along the radial direction. When one 21 is opposite, the through hole one communicates with the high pressure chamber 11 and the oil hole one 21, and the through hole two communicates with the low pressure chamber 12 and the oil hole one 21.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com